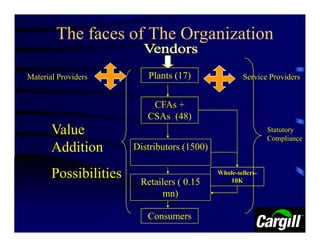

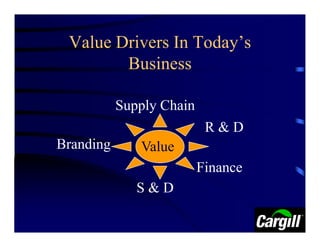

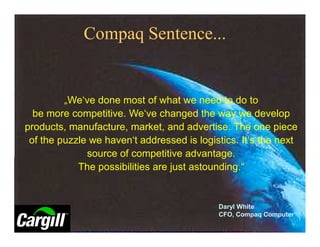

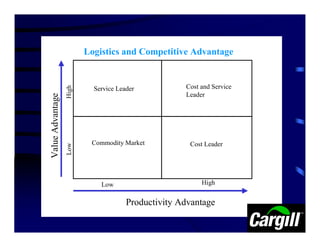

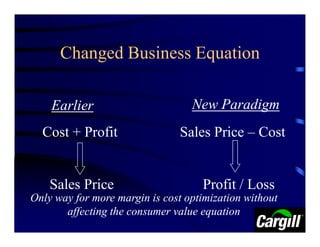

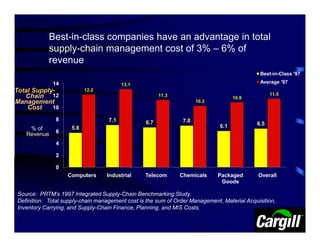

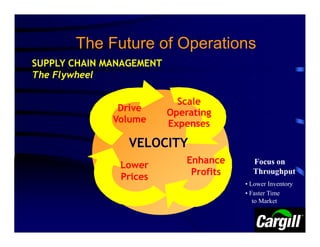

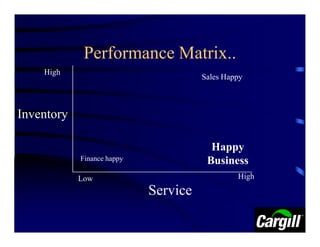

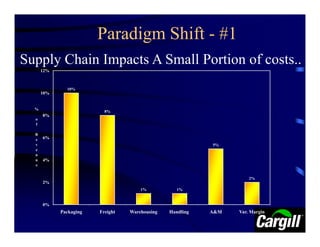

The document discusses supply chain management and its importance for competitive advantage. It outlines the key components of an organization's supply chain including material providers, plants, distributors, retailers, and consumers. Effective supply chain management can lower costs and increase productivity, creating advantages over competitors. The document also discusses how logistics and supply chain efficiencies can provide long-term competitive benefits through cost optimization without affecting consumer value. Overall, the document emphasizes that world-class companies use supply chain management to lower total costs by 3-6% of revenue compared to average companies.