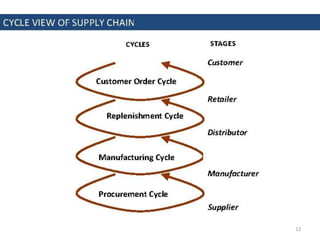

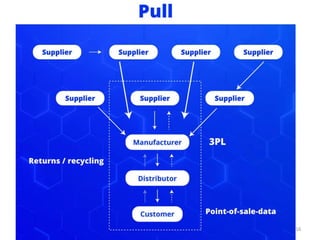

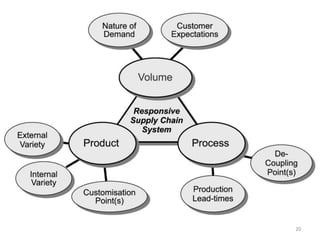

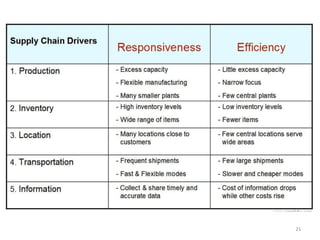

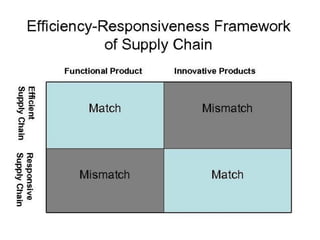

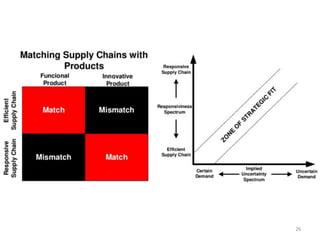

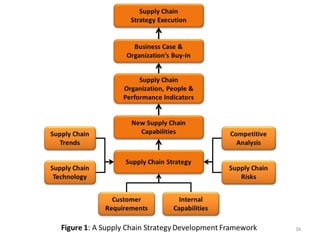

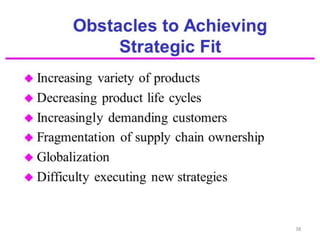

The document outlines various supply chain strategies, emphasizing the importance of having a well-defined roadmap to optimize sourcing, manufacturing, delivery, and logistics. It discusses four key strategies: placing buffers to absorb delays, diversifying sourcing networks to mitigate risks, investing in demand forecasting for better planning, and standardizing processes for consistency. Additionally, it addresses the concepts of push and pull supply chains, responsiveness, and the need for alignment between business and supply chain strategies.