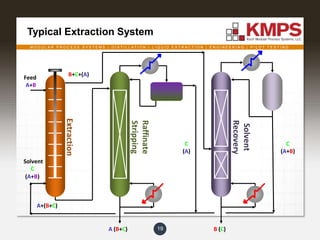

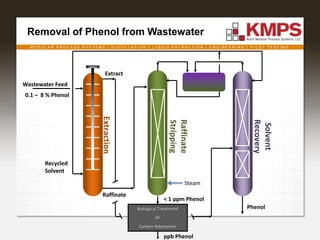

Koch Modular Process Systems (KMPS) specializes in the design and construction of mass transfer systems for the chemical processing industry, leveraging over 20 years of experience. The document outlines various applications of liquid-liquid extraction technology in industries such as chemicals, pharmaceuticals, petroleum, and food processing, detailing its advantages over distillation in certain scenarios. It also includes extraction methodologies, typical extraction systems, and specific case studies, such as removing phenol from wastewater.

![M O D U L A R P R O C E S S S Y S T E M S | D I S T I L L A T I O N | L I Q U I D E X T R A C T I O N | E N G I N E E R I N G | P I L O T T E S T I N G

Telephone: (201) 267-8670

www.modularprocess.com

7

Removal of Organics From Water:

Distillation vs. Extraction

Organic

Compound

BP [°C]

Water Solu.

[%]

Azeotrope

B.P. [°C]

Azeotrope

Water [%]

Typical Reduction

Level

Methylene Chloride 40 2.0 38.1 1.5 < 50 ppb

Acetone 56.2 Infinite Non Azeotropic < 50 ppb

Methanol 64.5 Infinite Non Azeotropic < 50 ppb

Benzene 80.1 0.18 69.4 8.9 < 50 ppb

Toluene 110.8 0.05 85.0 20.2 < 50 ppb

Formaldehyde -21 Infinite Non Azeotropic < 1,000 ppm

Formic Acid 100.8 Infinite 107.1 22.5 < 500 ppm

Acetic Acid 118.0 Infinite Non Azeotropic < 500 ppm

Pyridine 115.5 57 92.6 43 < 10 ppm

Aniline 181.4 3.60 99.0 80.8 < 10 ppm

Phenol 181.4 8.20 99.5 90.8 < 10 ppm

Nitrobenzene 210.9 0.04 98.6 88.0 < 10 ppm

Dimethyl Acetamide 166.1 Infinite Non Azeotropic < 10 ppm

n-Methylpyrrolidone 202.0 Infinite Non Azeotropic < 10 ppm

DistillationExtraction](https://image.slidesharecdn.com/kmps-liquidliquidextraction-151021160016-lva1-app6891/85/Liquid-Liquid-Extraction-7-320.jpg)

![M O D U L A R P R O C E S S S Y S T E M S | D I S T I L L A T I O N | L I Q U I D E X T R A C T I O N | E N G I N E E R I N G | P I L O T T E S T I N G

Telephone: (201) 267-8670

www.modularprocess.com

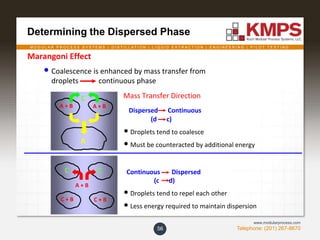

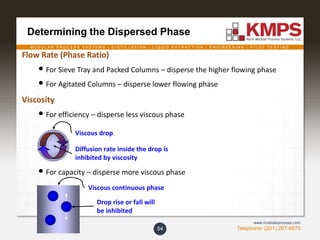

Determining the Dispersed Phase

55

Surface Wetting

• Want the continuous phase to preferentially wet the internals – this

minimizes coalescence and therefore maximizes interfacial area.

Importance of maintaining droplets

Assume – 30% holdup of dispersed phase in 1 M3 of solution

Droplets coalesce.

Interfacial area lost.

Droplets retain shape.

Maximizes interfacial area.

Droplet

Diameter [m]

Droplet

Volume [M3]

Number

Droplets

Droplet SA

[M2]

Interfacial Area

[M2/M3]

100 0.3 7.16x1010 1.26x10-7 9022

300 0.3 2.65x109 1.13x10-6 2995

500 0.3 5.73x108 3.14x10-6 1796](https://image.slidesharecdn.com/kmps-liquidliquidextraction-151021160016-lva1-app6891/85/Liquid-Liquid-Extraction-55-320.jpg)