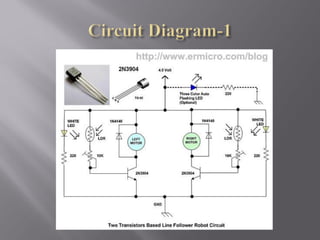

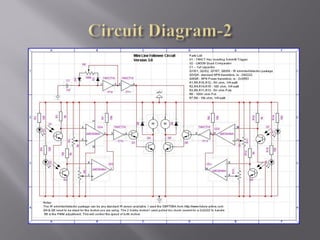

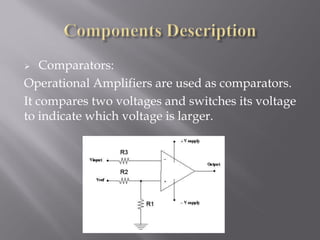

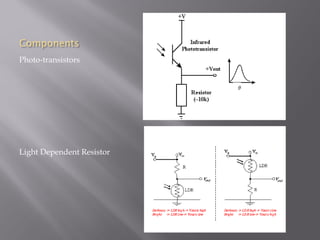

This document outlines a semester project to build a line-following robot. It will use discrete electronic components like light dependent resistors and transistors to sense a white line on a black surface and motors to maneuver along the line. The project will have modules for mechanical design, motor control, and light sensing. It provides details on the components, circuit design, team responsibilities, timeline and potential risks.