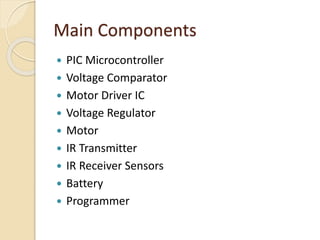

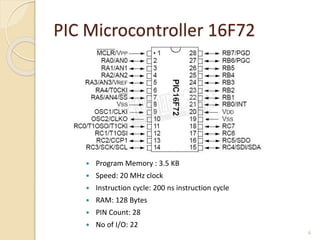

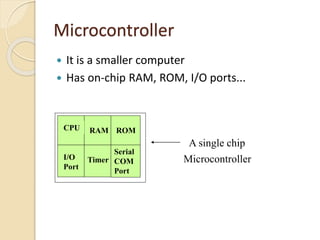

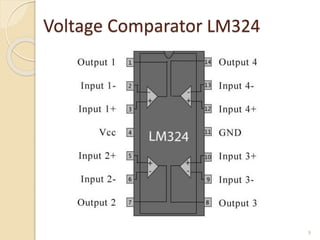

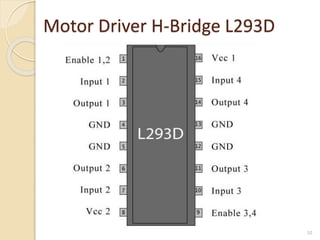

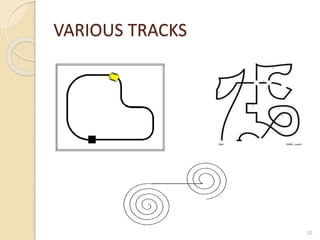

The document describes a line following robot with obstacle detection capabilities. It uses a PIC microcontroller, IR sensors, motors and other components. The robot follows a black line but can detect and stop for objects in its path, then continue once the object is removed. It has applications in automated delivery systems, factories and tours. The hardware and software work together to sense the line and navigate corners while avoiding obstacles.