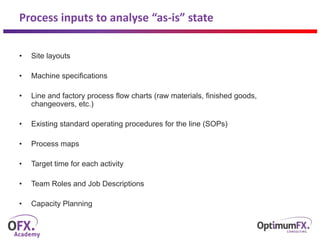

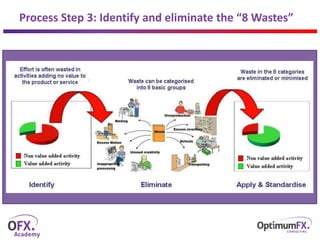

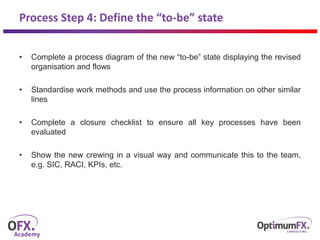

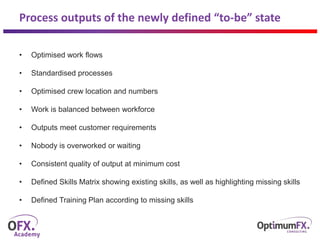

Line crew optimization is a methodology designed to enhance production line efficiency by balancing labor costs, quality, and productivity through a continuous improvement approach. It involves analyzing existing processes, mapping workflows, and eliminating waste, while ensuring every team member has defined roles and responsibilities. The outcome is a streamlined operation that meets customer requirements while maintaining team balance and minimizing downtime.