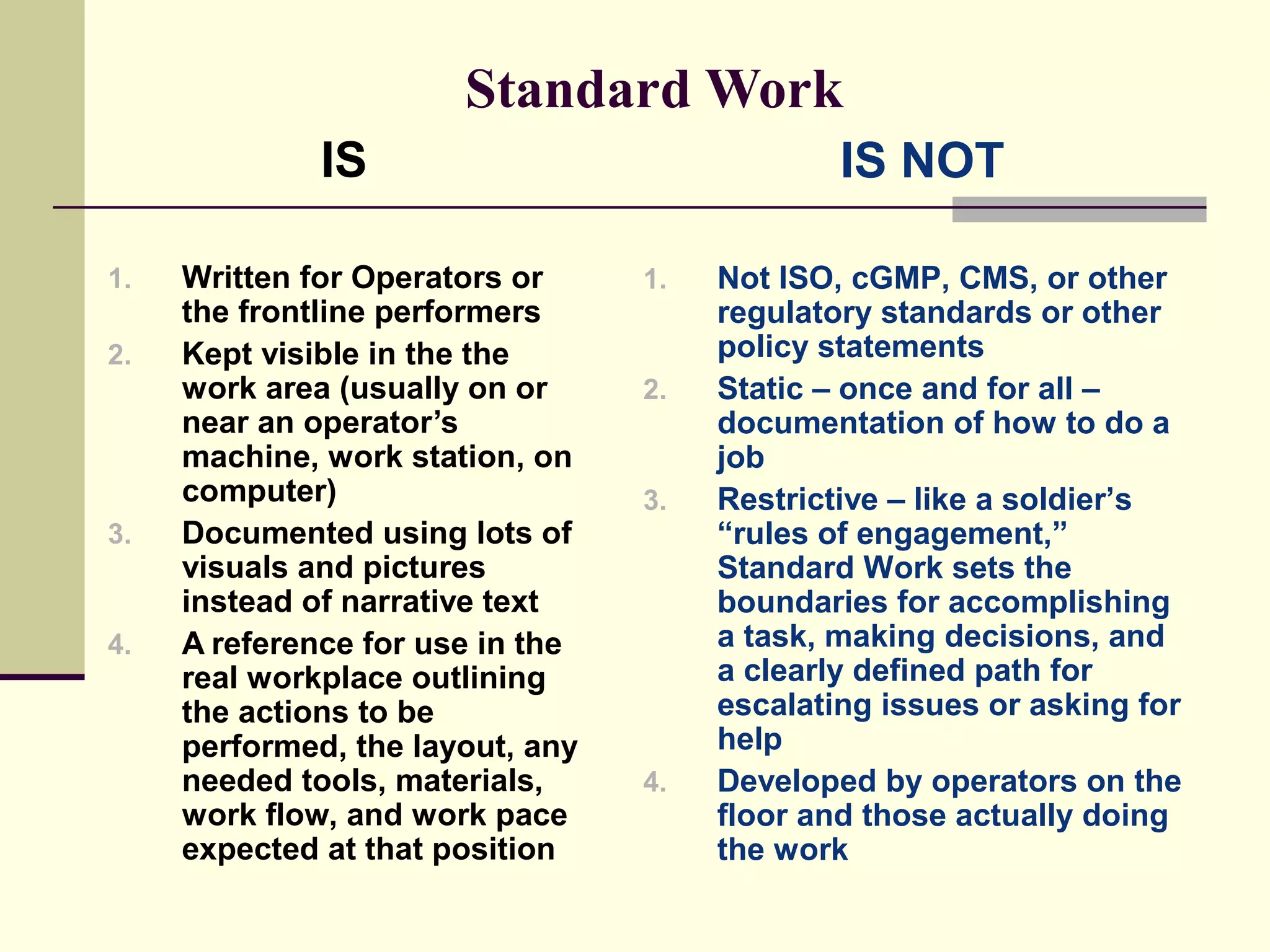

This document discusses standard work and its importance in organizations. Standard work is defined as the best, safest, and most efficient way to complete a specific task. It provides structure and consistency. Standard work benefits organizations by reducing variation, eliminating waste, ensuring safety and compliance, and allowing for continuous improvement. The document outlines how to create standard work and the different types. It notes that standard work, while difficult to develop, allows organizations to sustain gains and serves as a baseline for further improvement.