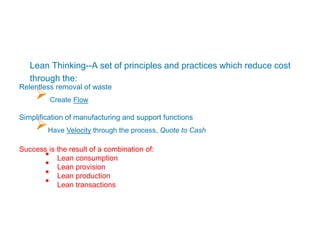

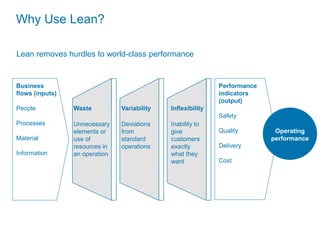

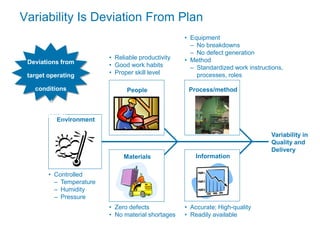

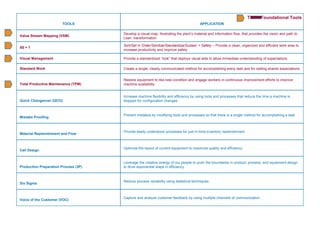

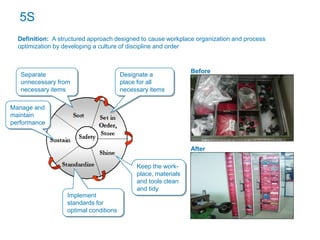

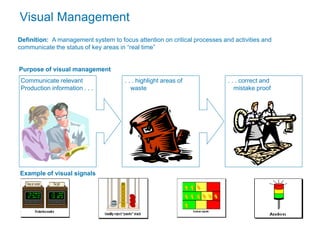

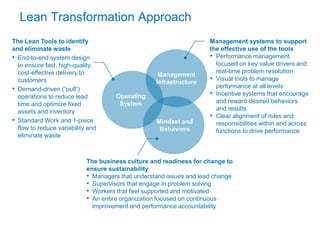

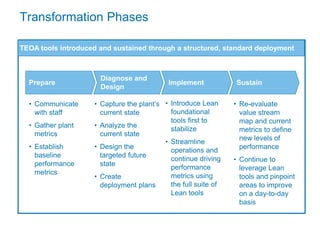

The document provides an overview of Lean, including its principles of reducing waste and increasing flow to improve performance. It describes the Lean approach and tool kit to drive operational improvements through a structured transformation approach involving roles, tools, and phases to prepare, diagnose, implement, and sustain Lean practices. The goal is to remove variability and inflexibility through techniques like 5S, visual management, and standard work to meet customer demands with higher quality, lower costs, and lead times.

![Prepare Phase

Implement Sustain

Prepare Diagnose and Design

Safety Inventory

Quality Plant-specific

data

Delivery Cost

Collect Site Data Baseline Site Performance

Total

productivity

improvement

Total production cost in factory

(labor [direct and indirect] + fixed +

consumables + variable + transfer)

Total standard hours earned

=

$ 76

$ 83

$ 82

$ 86

$ 76

$ 79

$ 71

$ 72

$ 64

$ 62

0

10

20

30

40

50

60

70

80

90

FY 08

May

FY 05 FY 06 FY 07 FY 08

Oct

FY 08

Nov

FY 08

Dec

FY 08

Jan

FY 08

Feb

FY 08

Mar

$ 70

FY 08

Apr

+6%

$ / hr](https://image.slidesharecdn.com/leanintroduction-220828090219-d9e67ec0/85/Lean-Introduction-pptx-25-320.jpg)