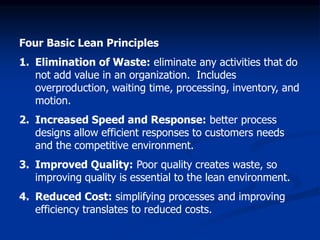

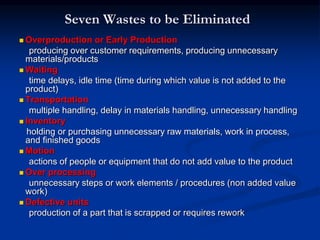

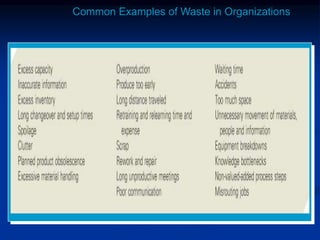

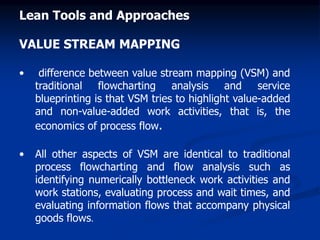

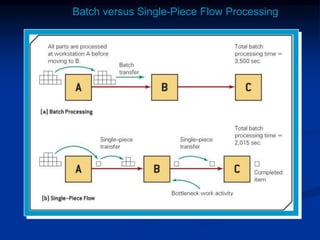

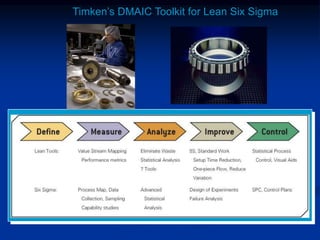

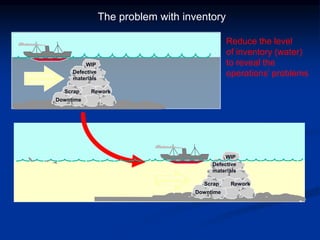

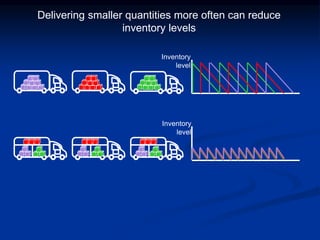

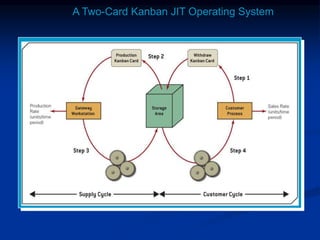

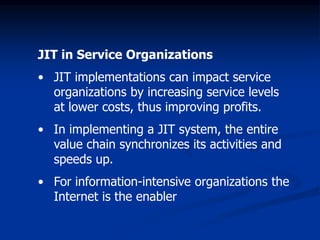

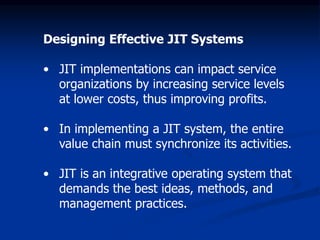

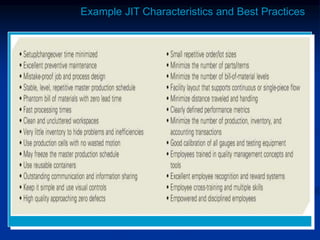

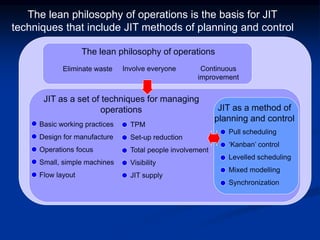

The document discusses Lean Thinking and Just-in-Time (JIT) systems. It defines Lean as doing more with less waste and focusing on core capabilities. The key principle of Lean is eliminating all waste to become faster, more dependable, higher quality, and lower cost. JIT aims to meet demand instantly with no waste. The document outlines Lean tools like value stream mapping, small batch production, visual controls, and 5S. It also discusses JIT techniques like pull scheduling, Kanban control, and levelled production to minimize inventory levels. Lean and JIT both focus on eliminating waste to improve productivity, quality and reduce costs.