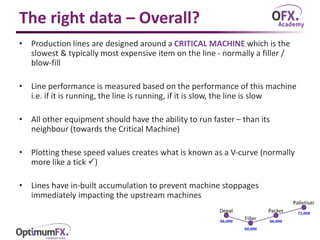

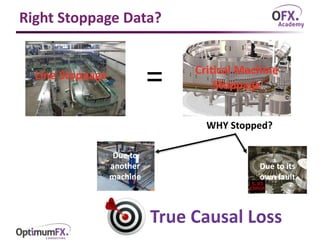

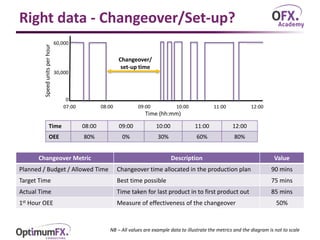

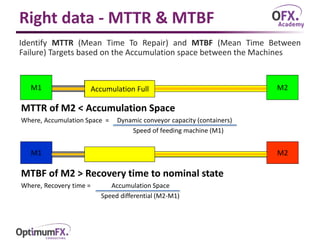

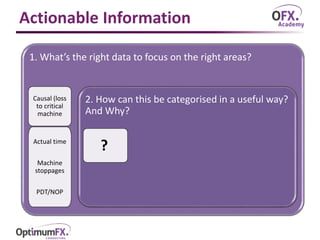

The document discusses how to improve packaging line performance by identifying and analyzing the correct data, focusing on the performance of the slowest critical machine. It emphasizes the importance of measuring line performance, categorizing machine stoppages, and calculating metrics like mean time to repair (MTTR) and mean time between failures (MTBF). Additionally, it explores the use of a v-curve for visualizing machine speeds and optimizing efforts based on actionable information.