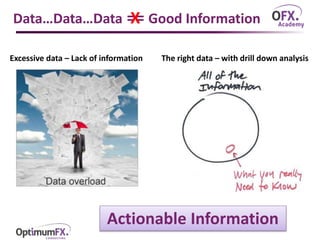

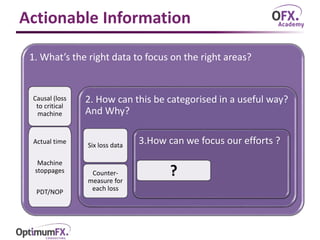

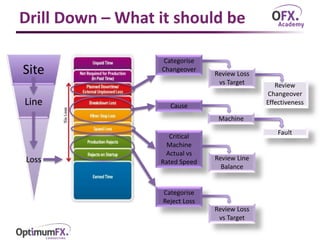

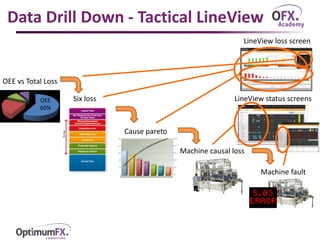

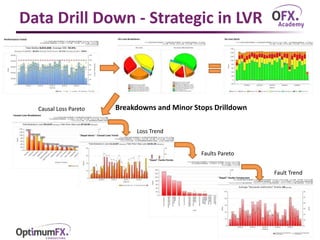

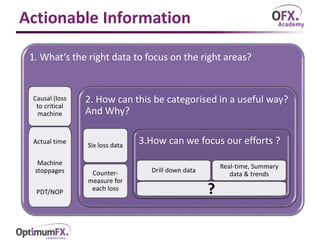

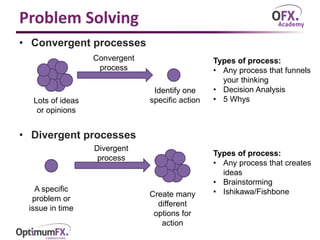

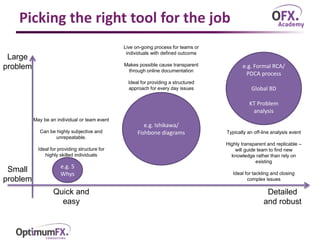

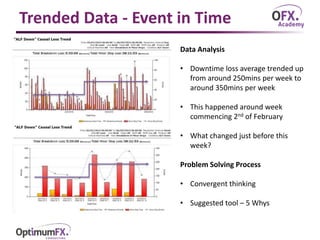

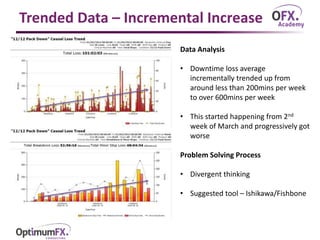

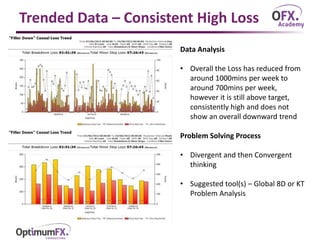

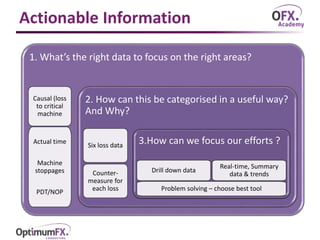

The document discusses improving packaging line performance through targeted data analysis and problem-solving processes. It emphasizes the importance of identifying the right data, categorizing losses, and using appropriate tools like 5 Whys and Ishikawa diagrams to analyze issues. The analysis reveals trends in downtime loss and encourages a systematic approach to effectively address performance issues.