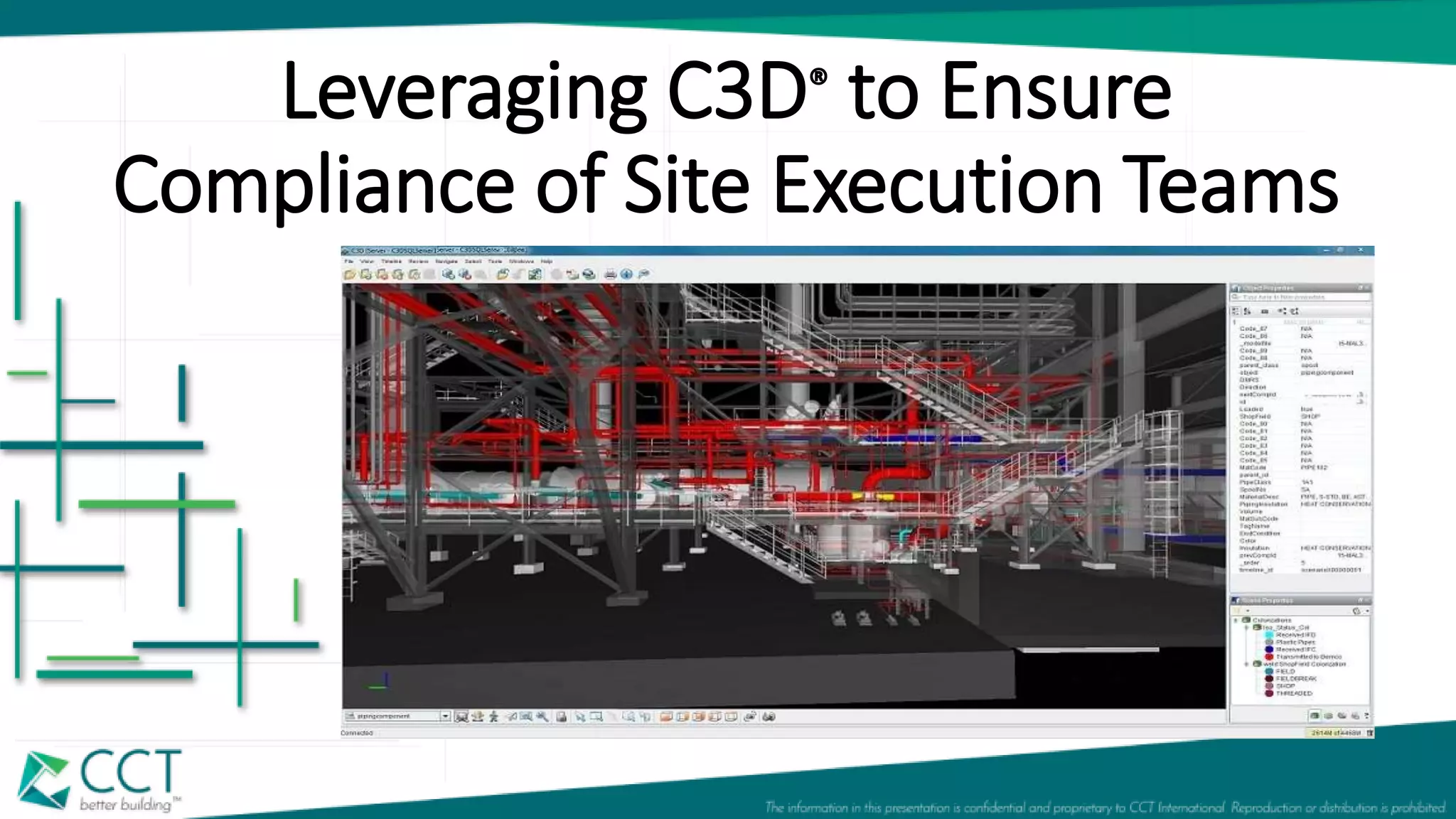

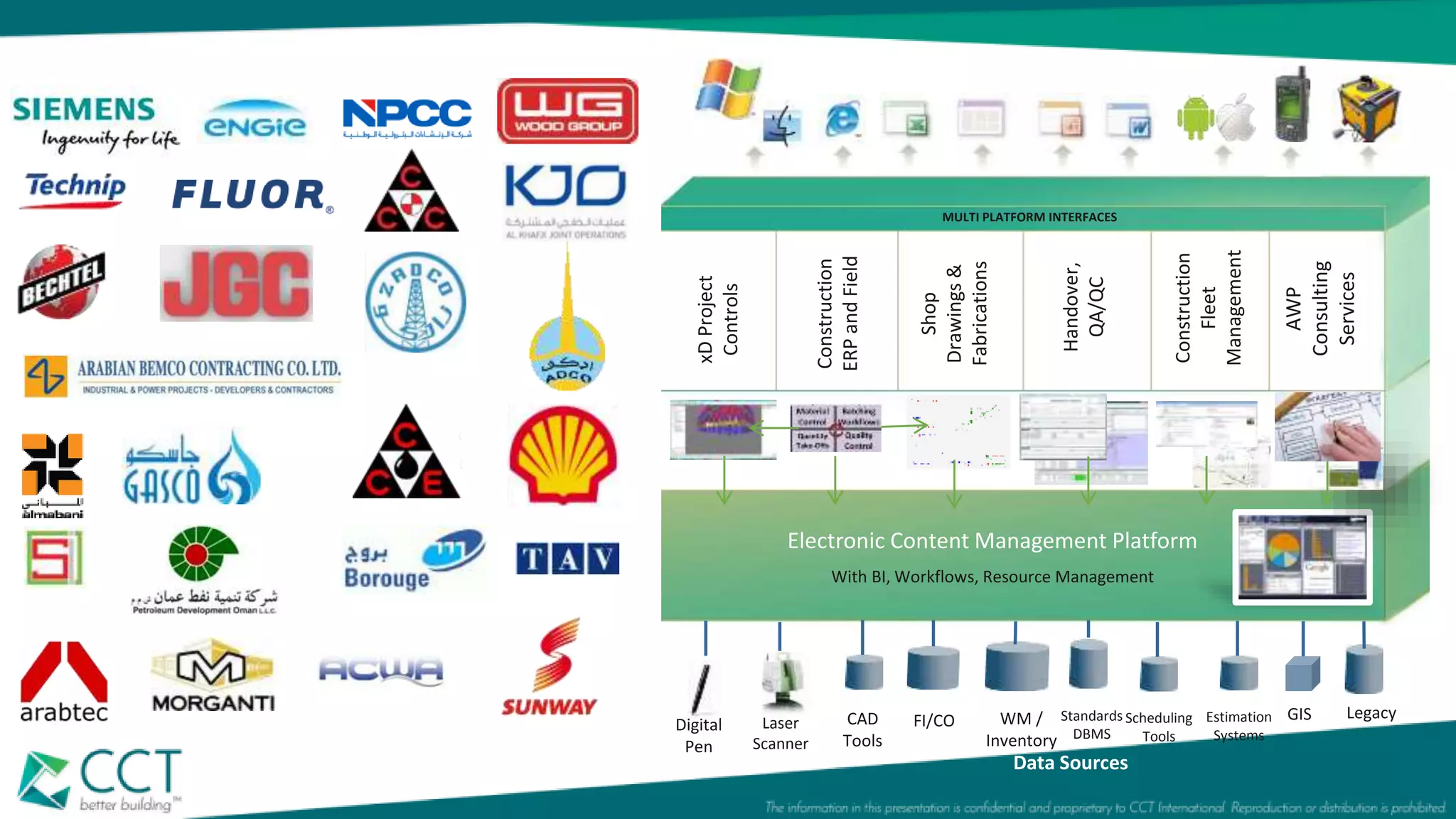

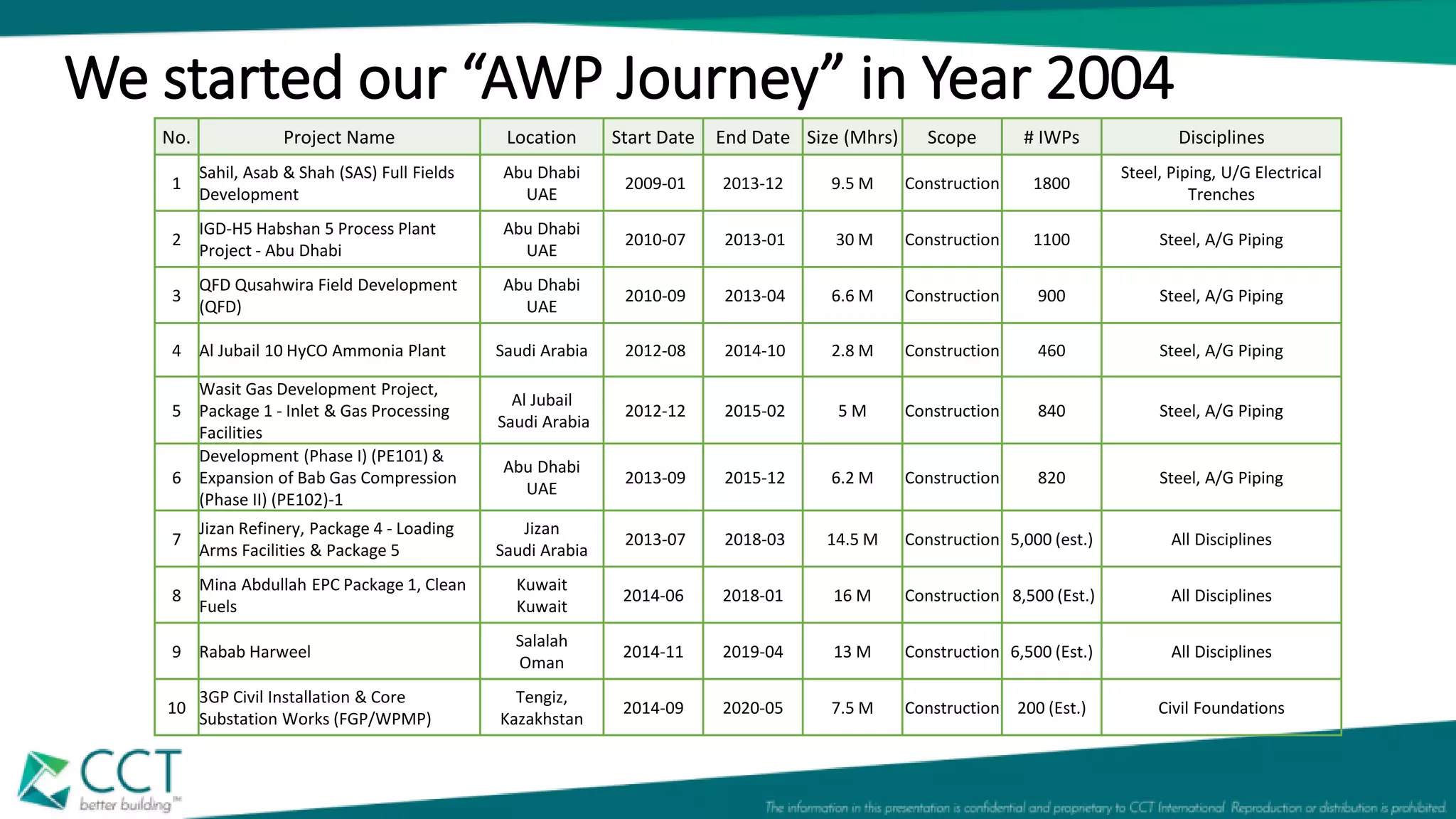

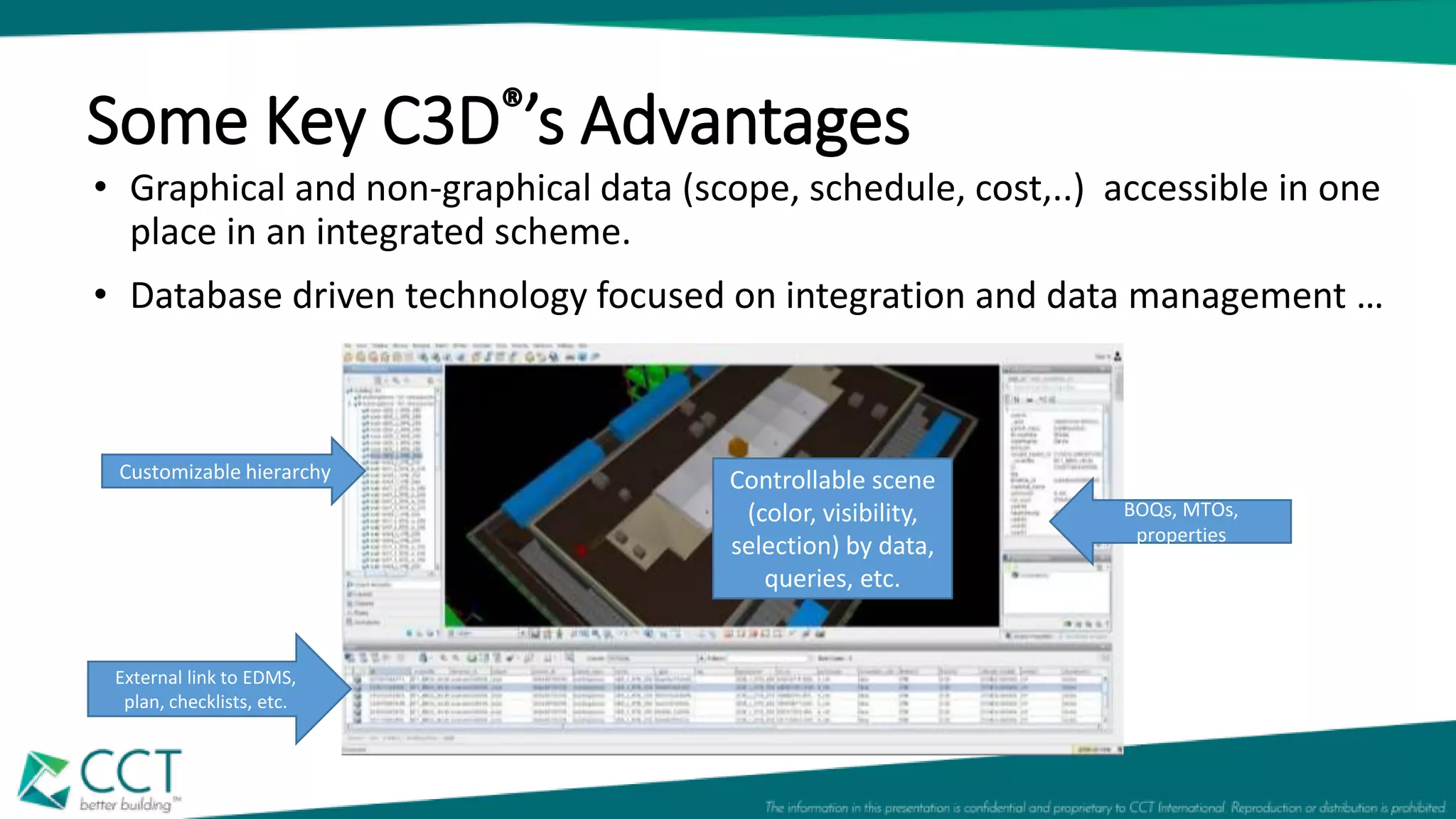

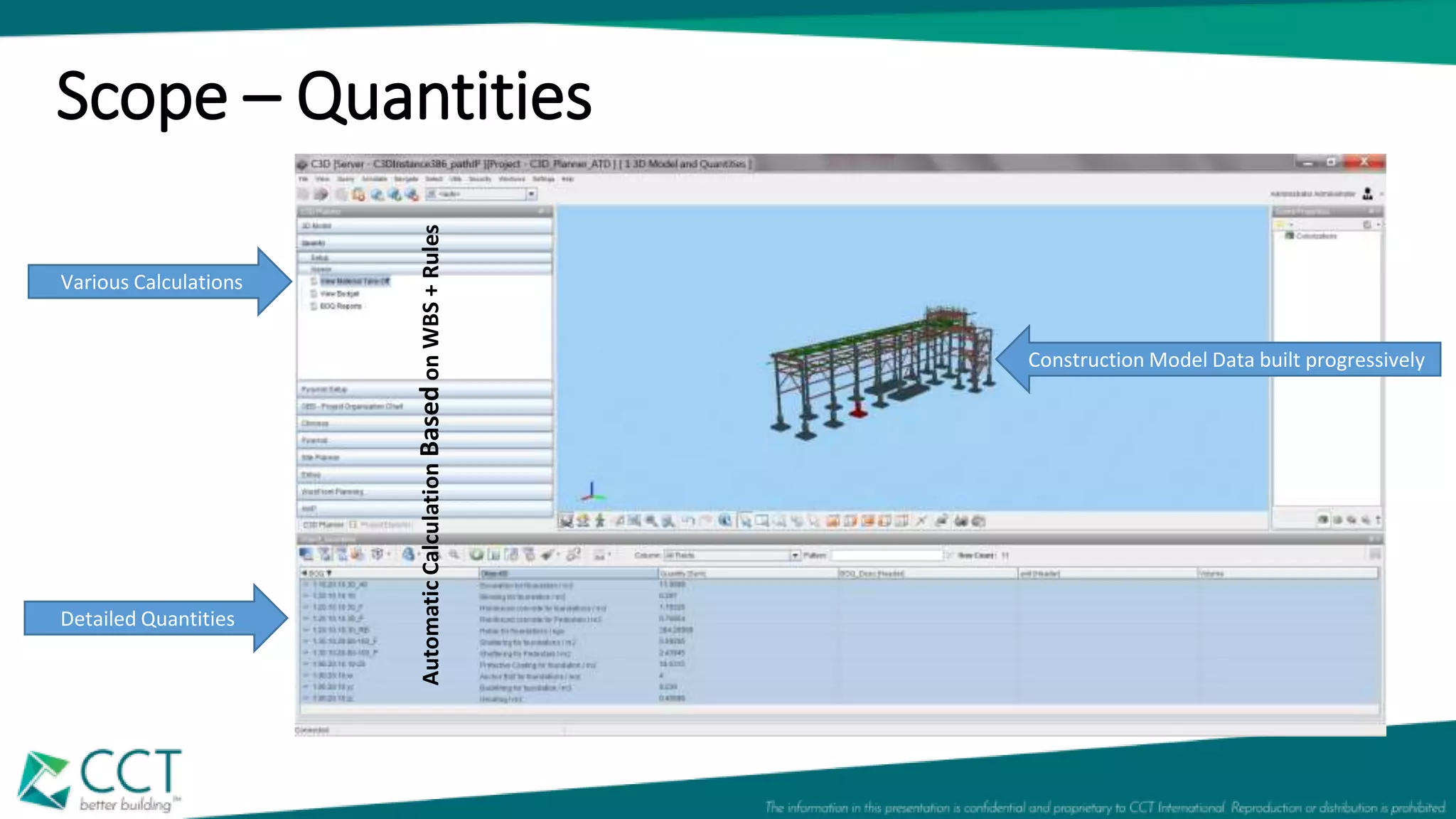

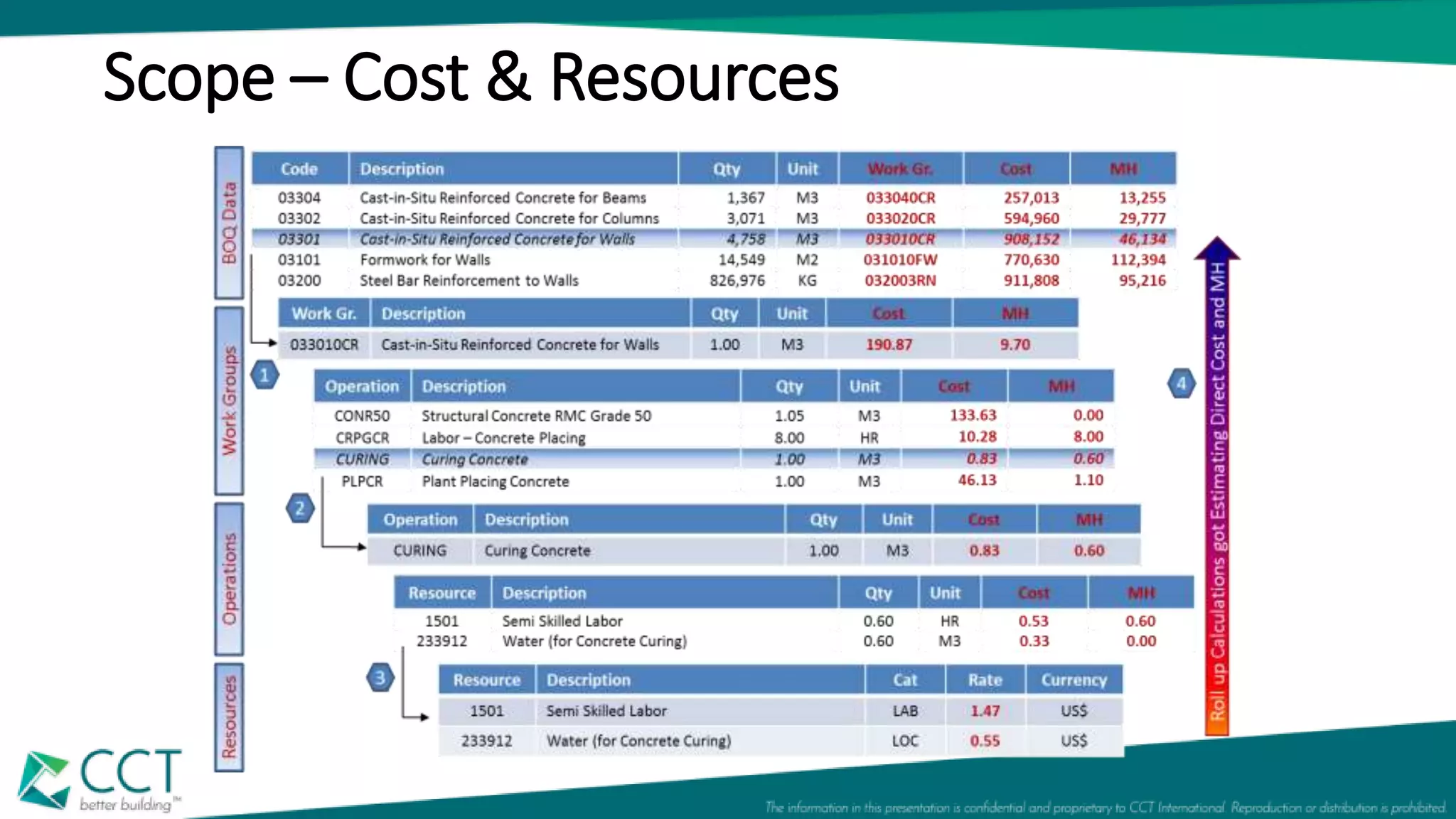

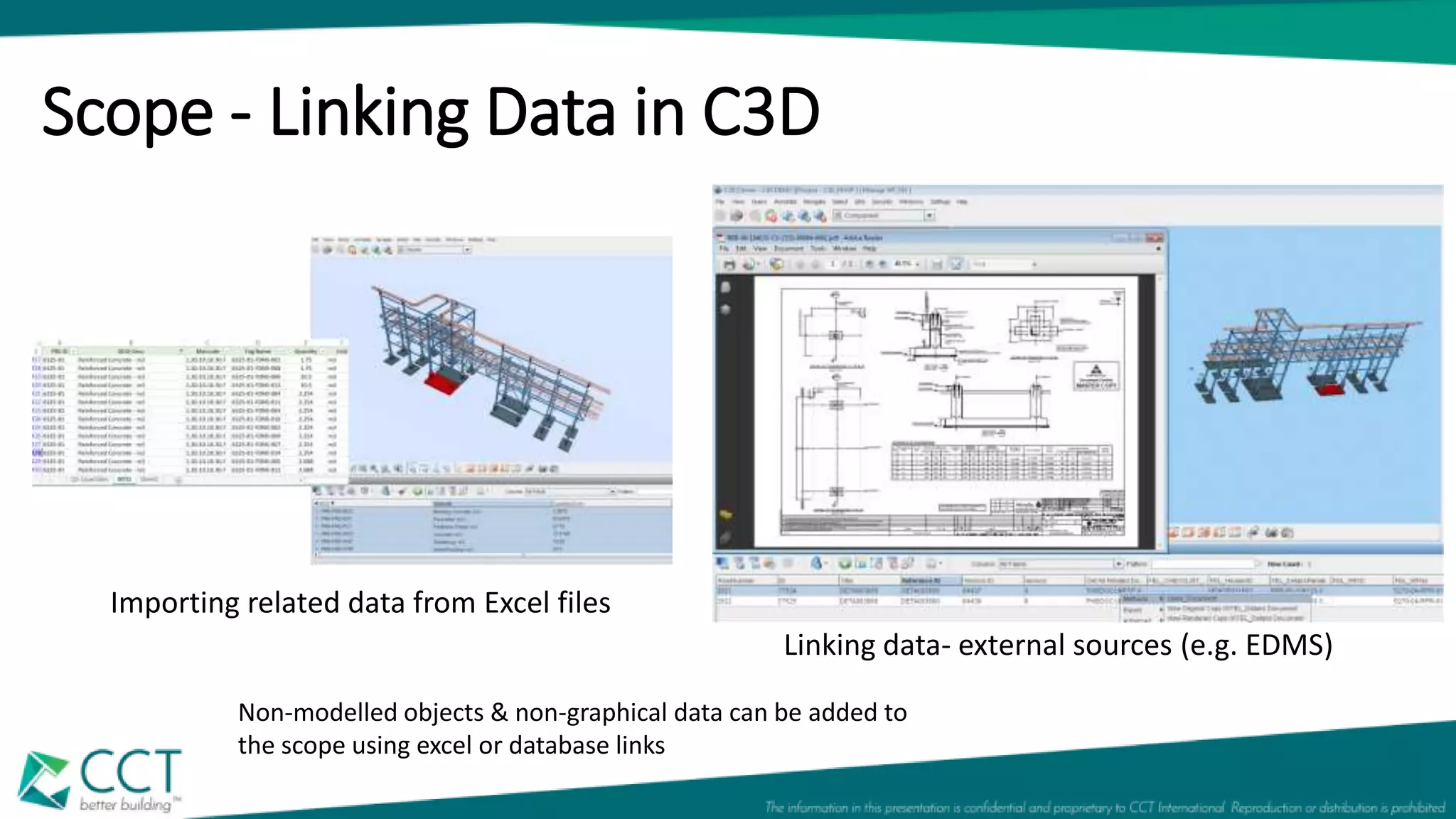

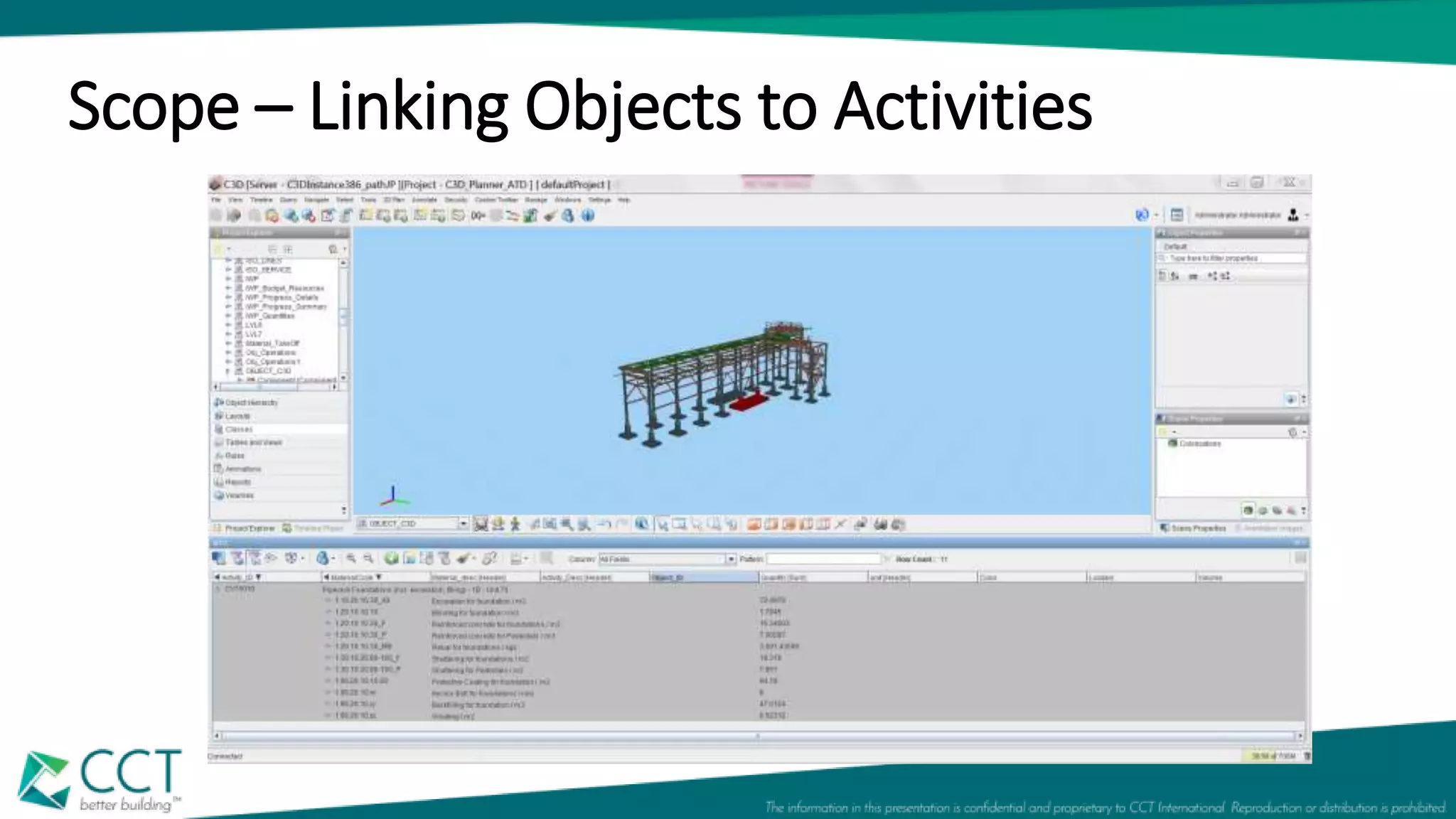

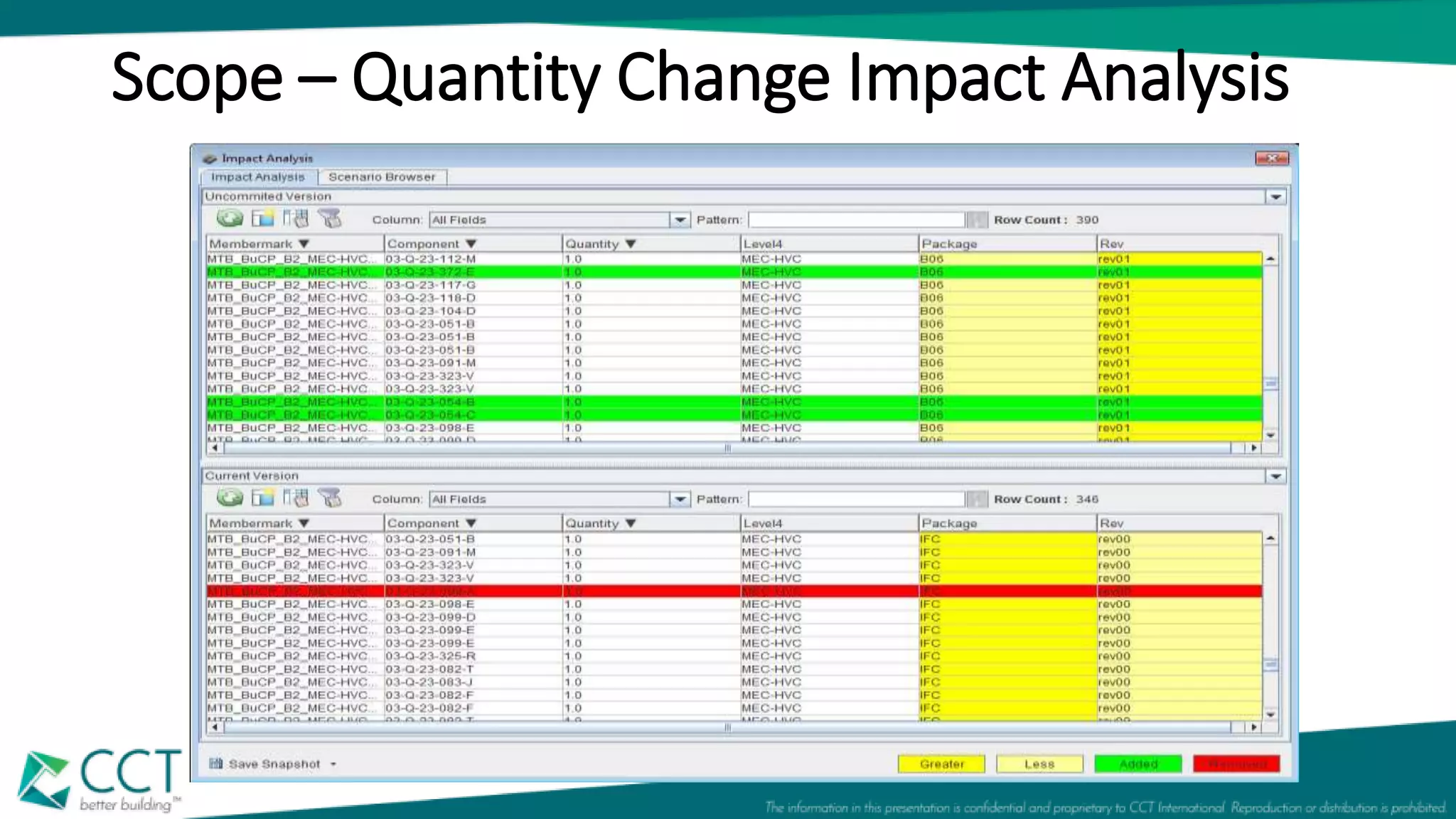

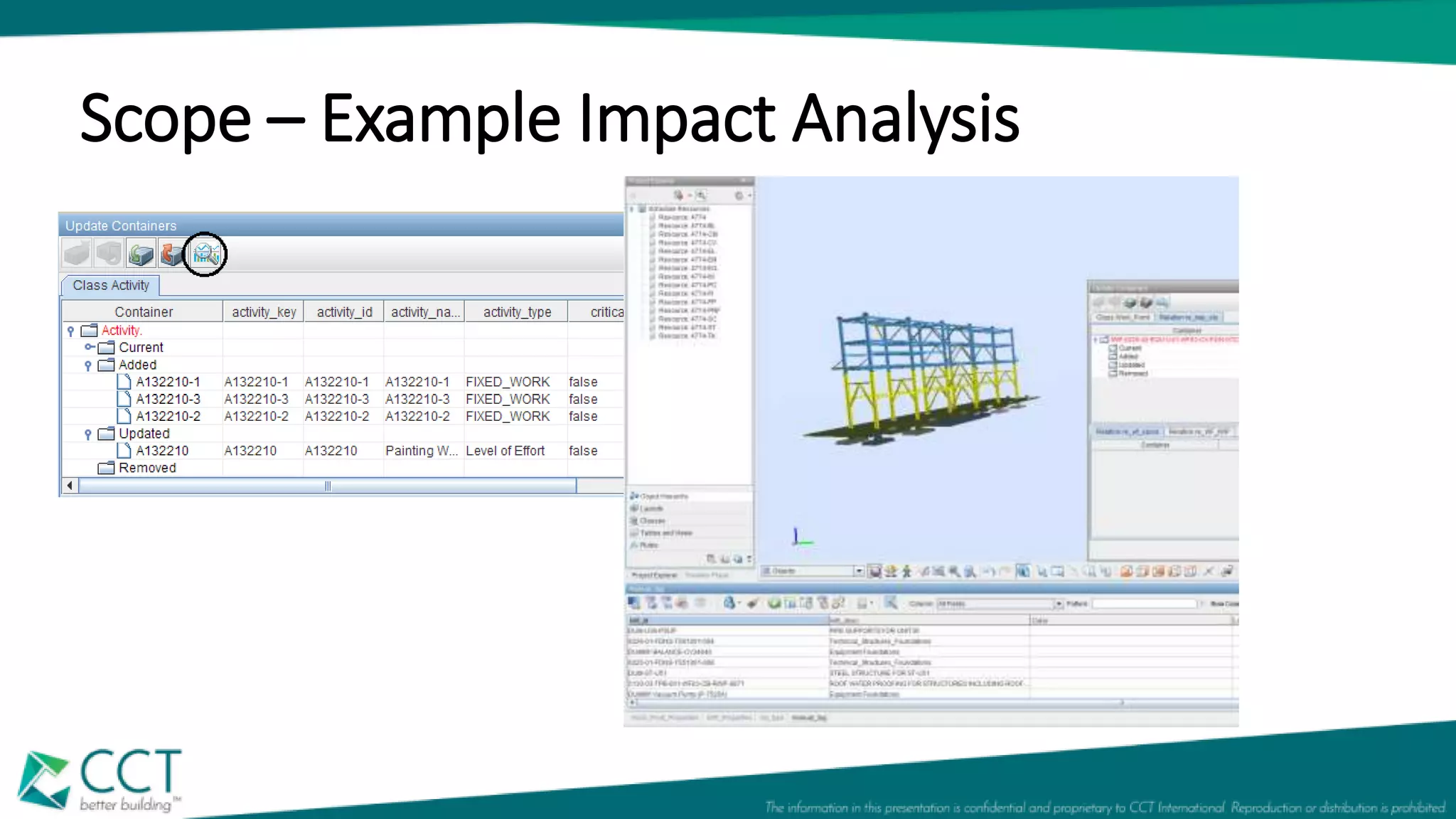

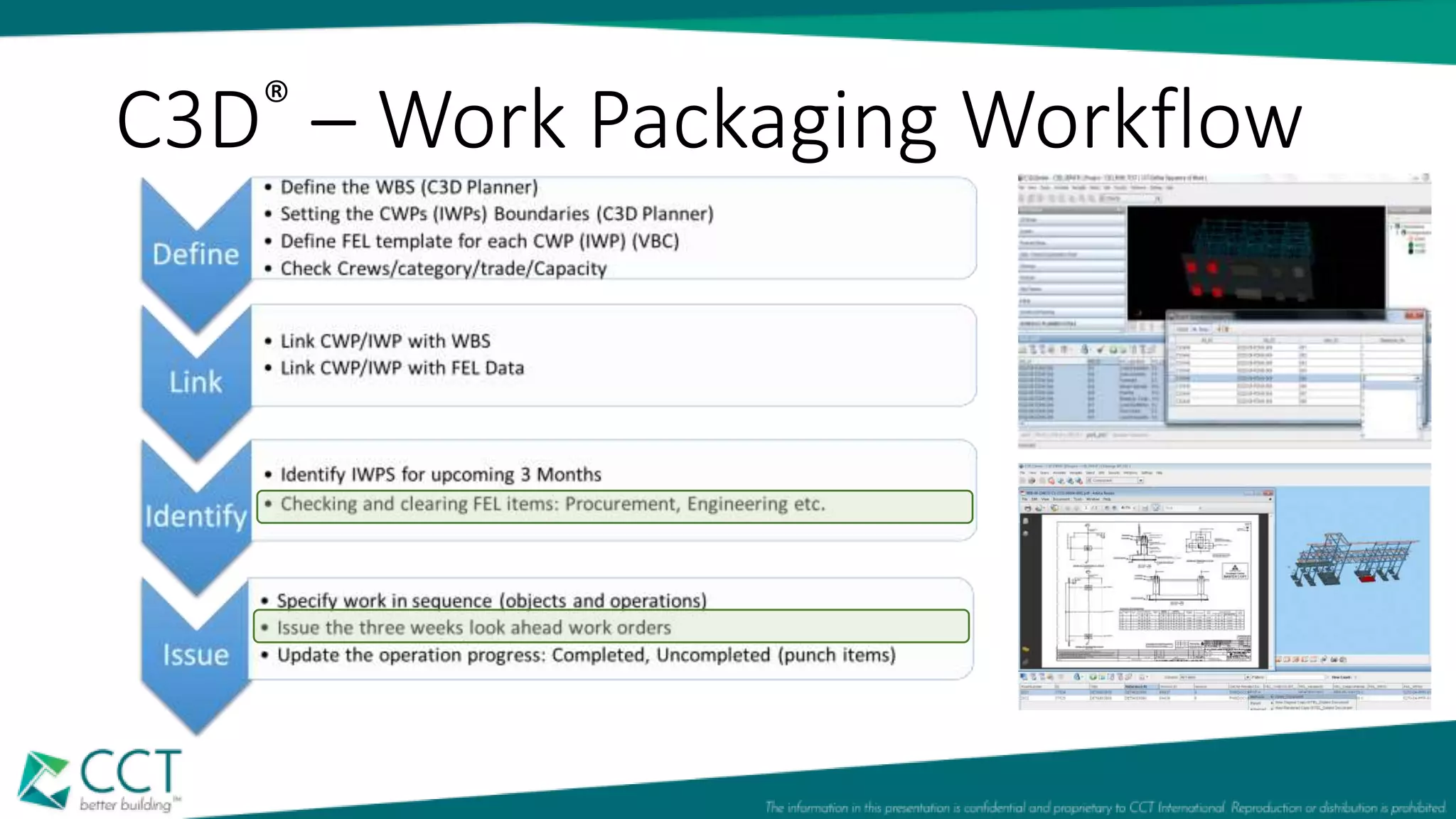

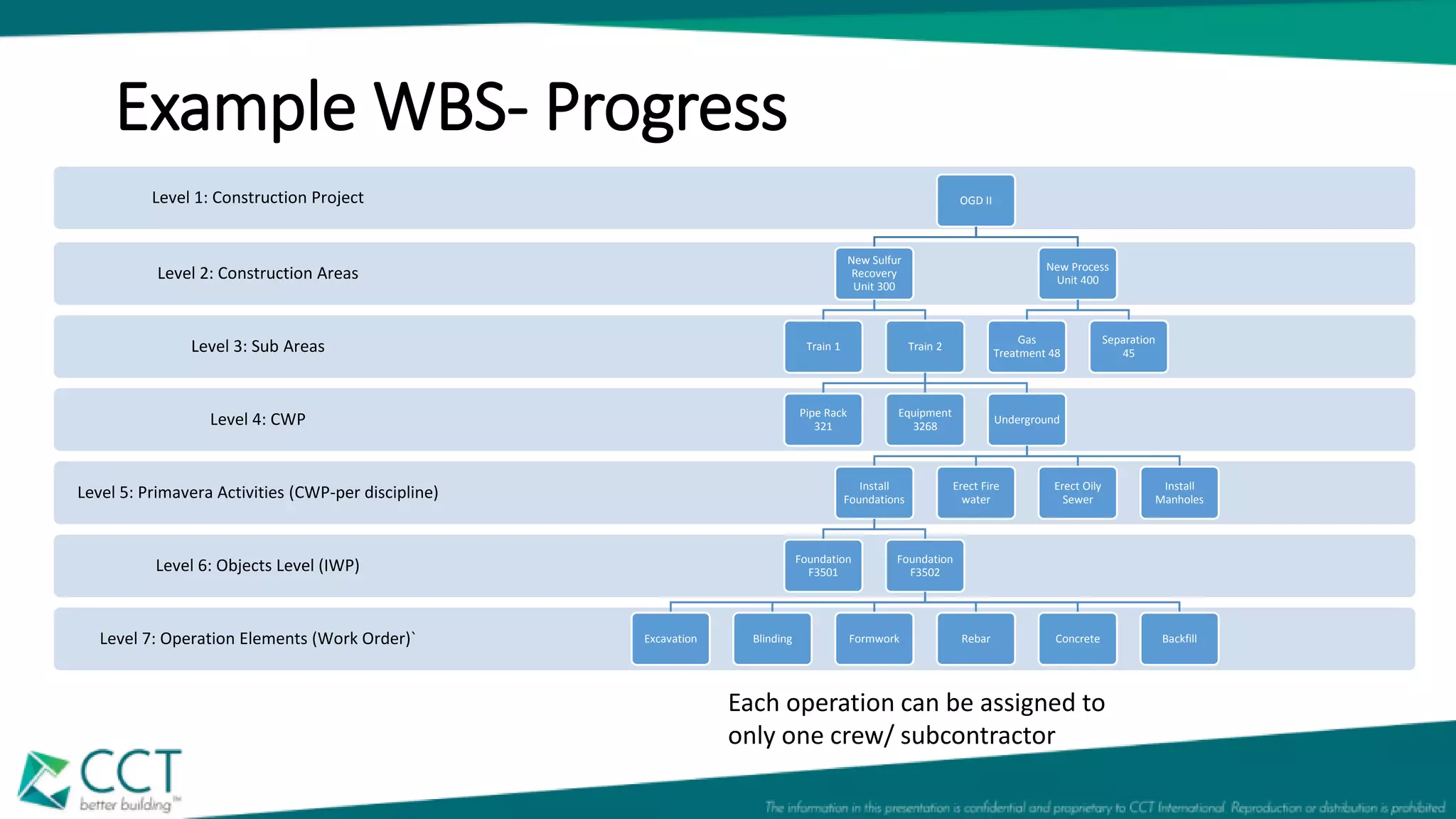

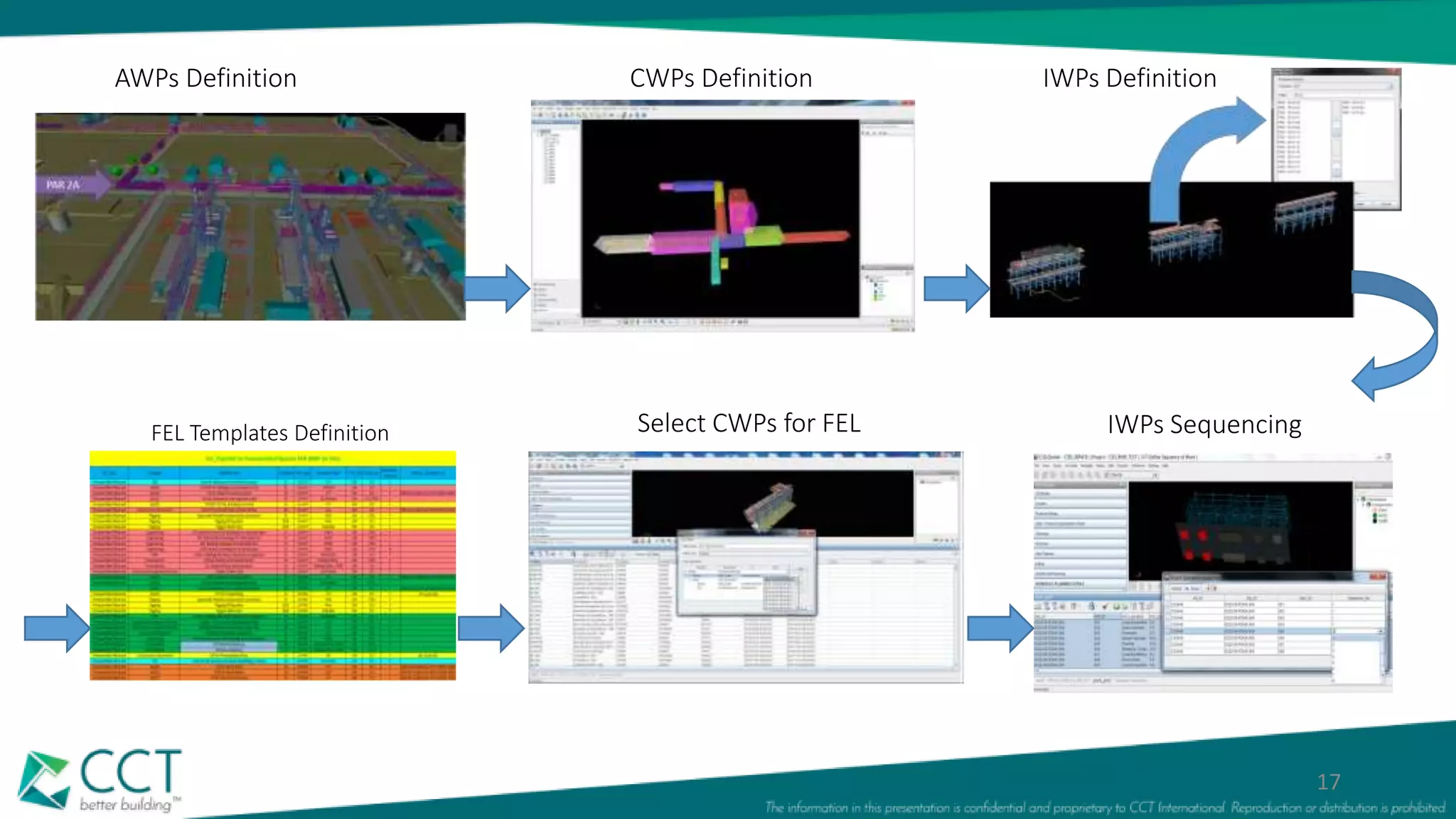

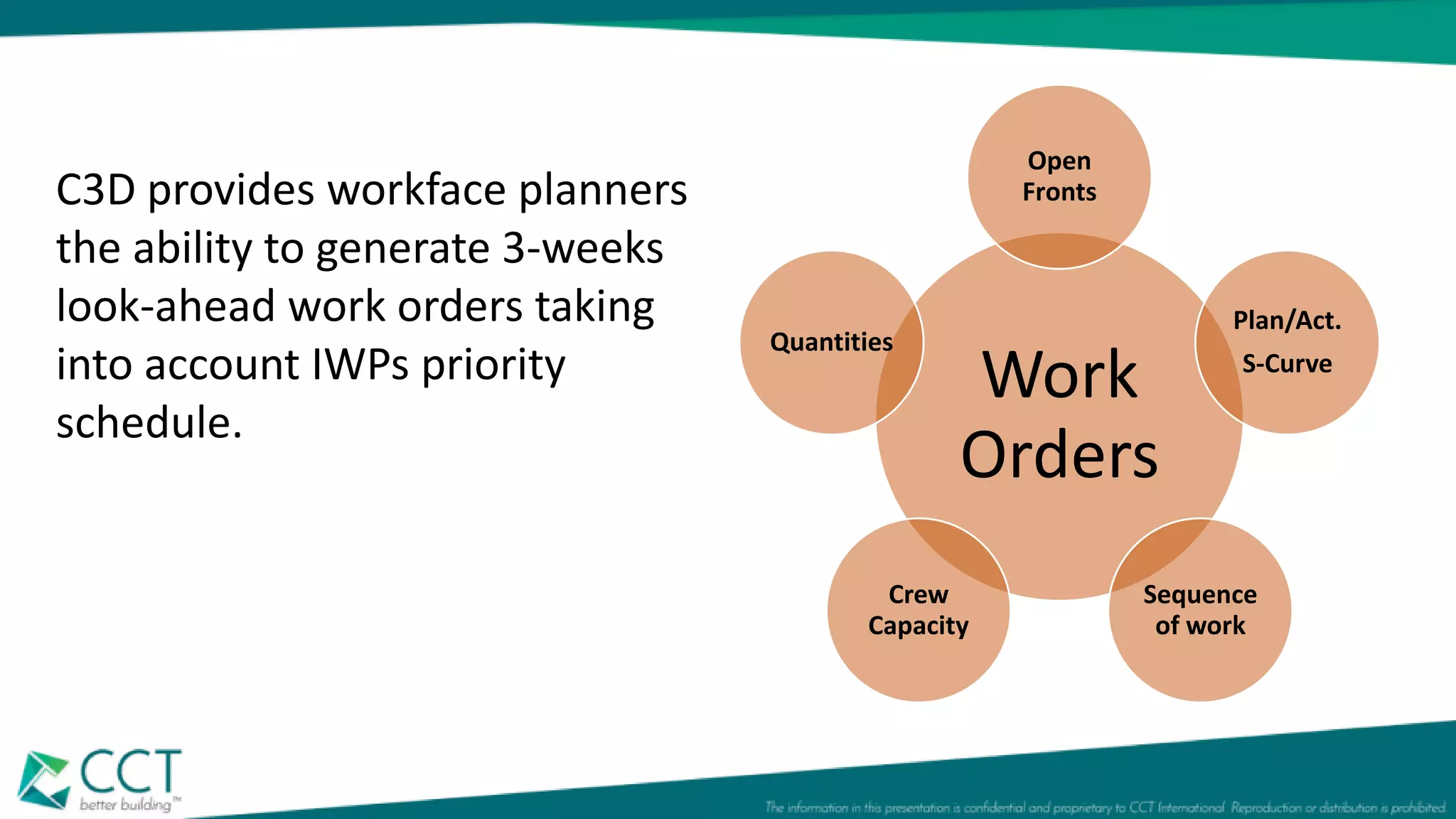

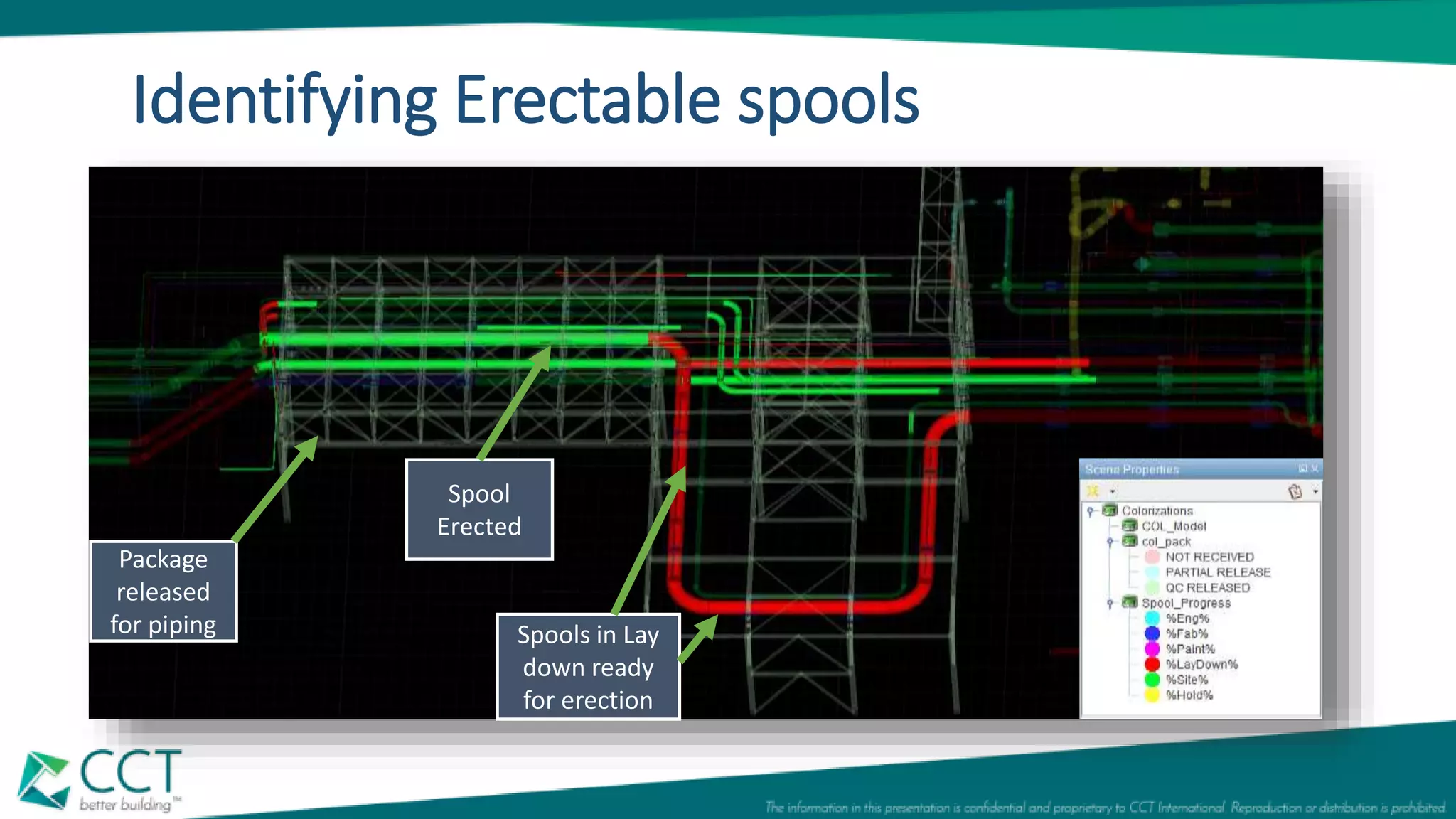

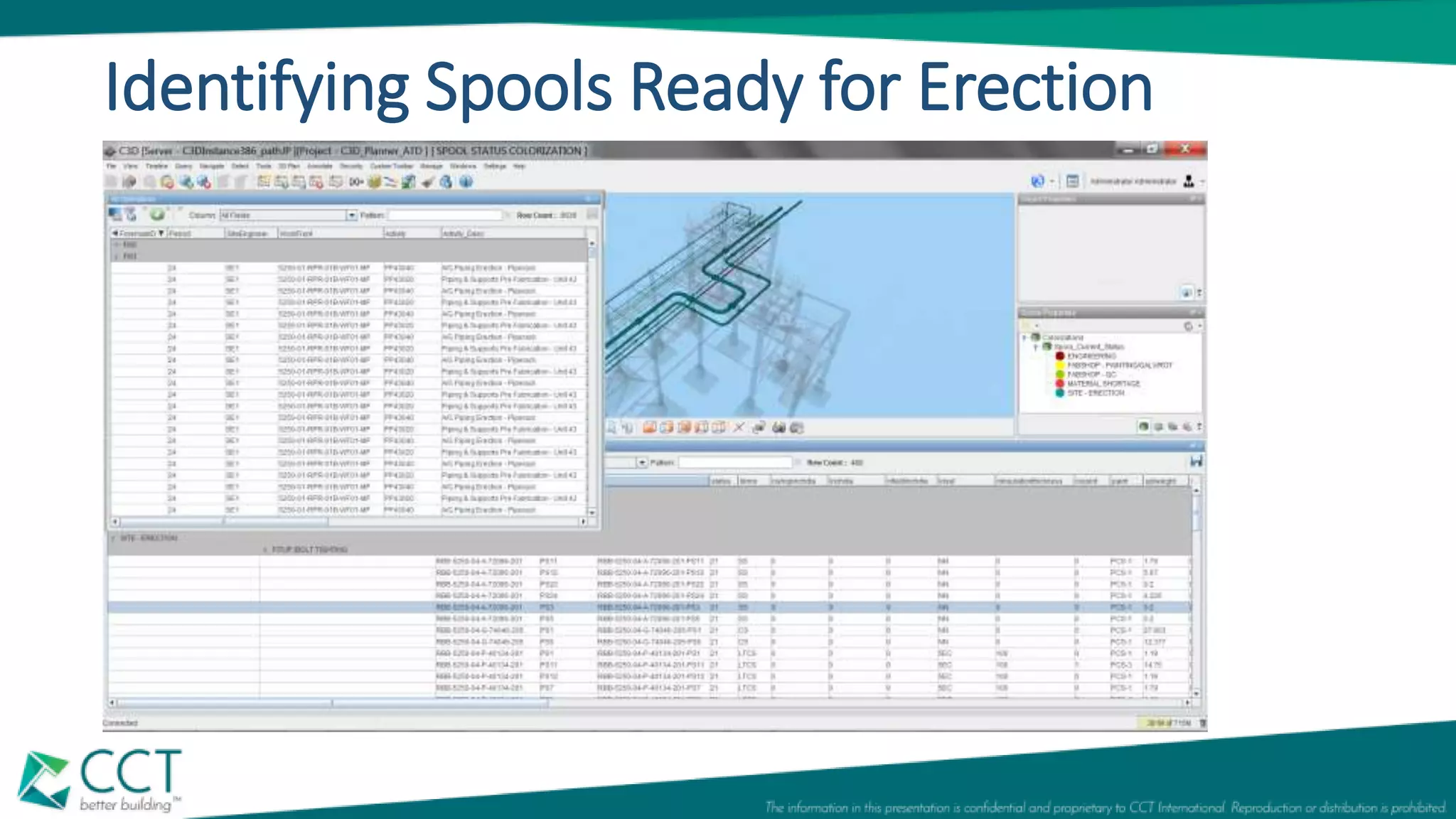

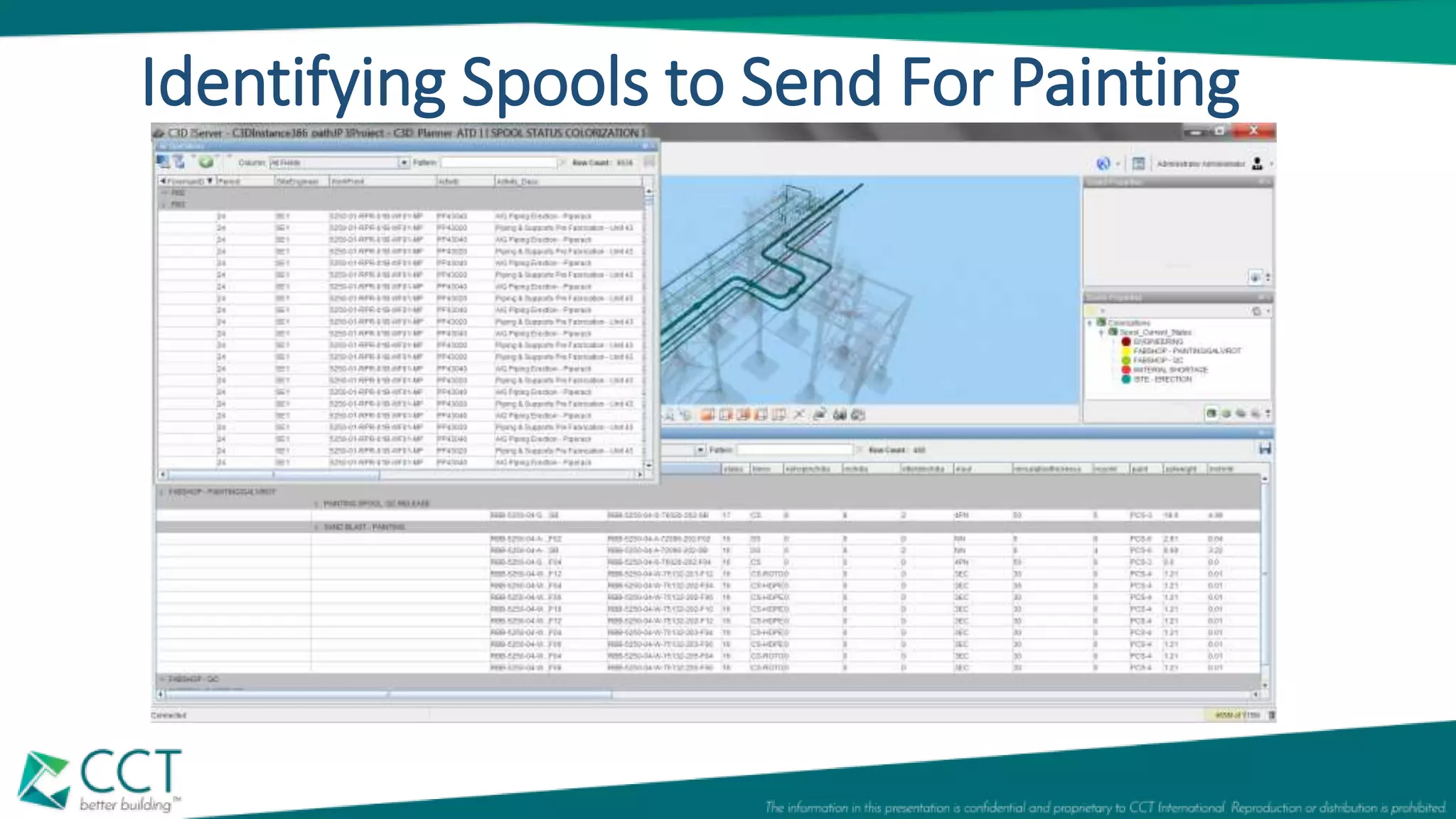

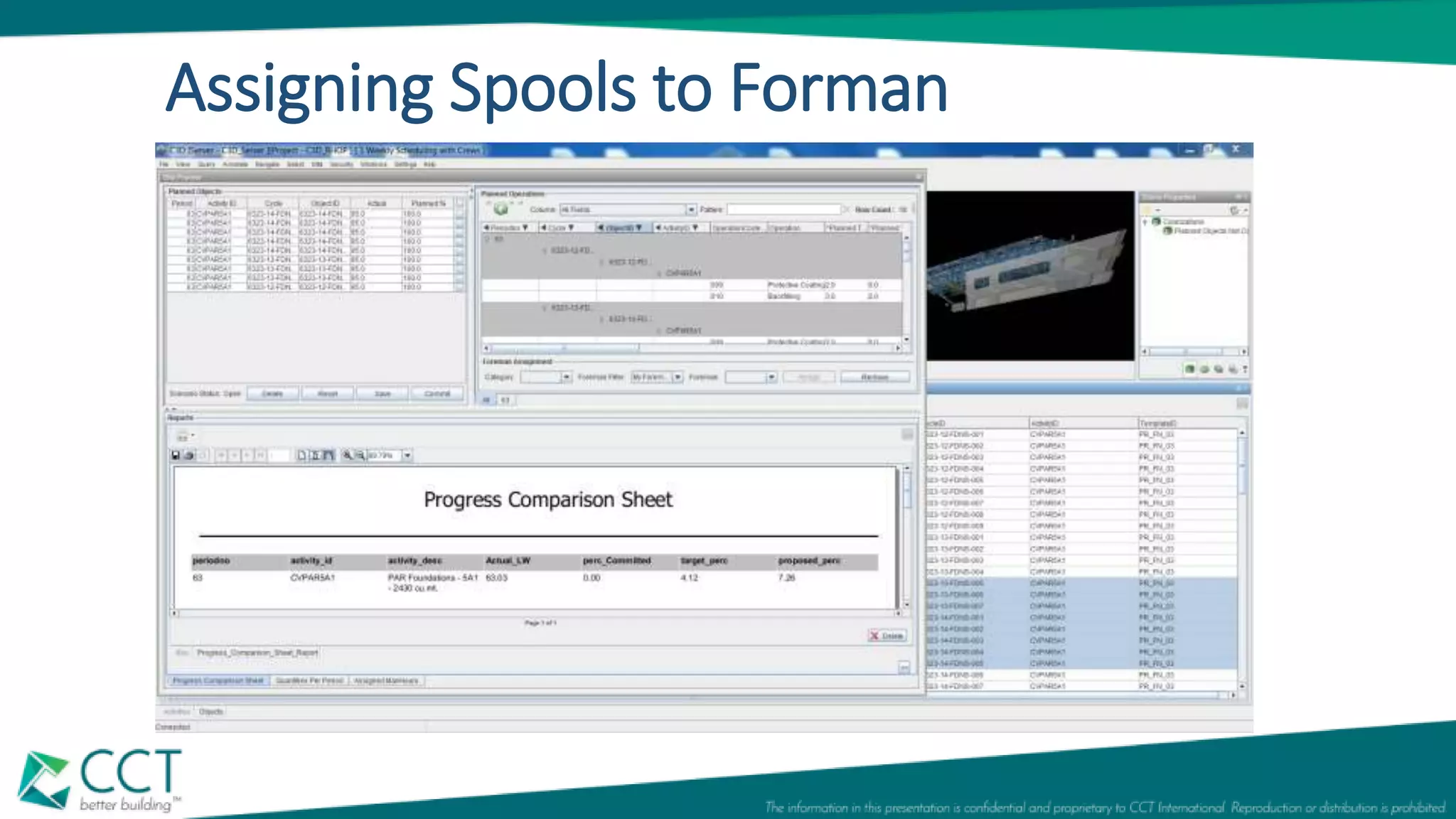

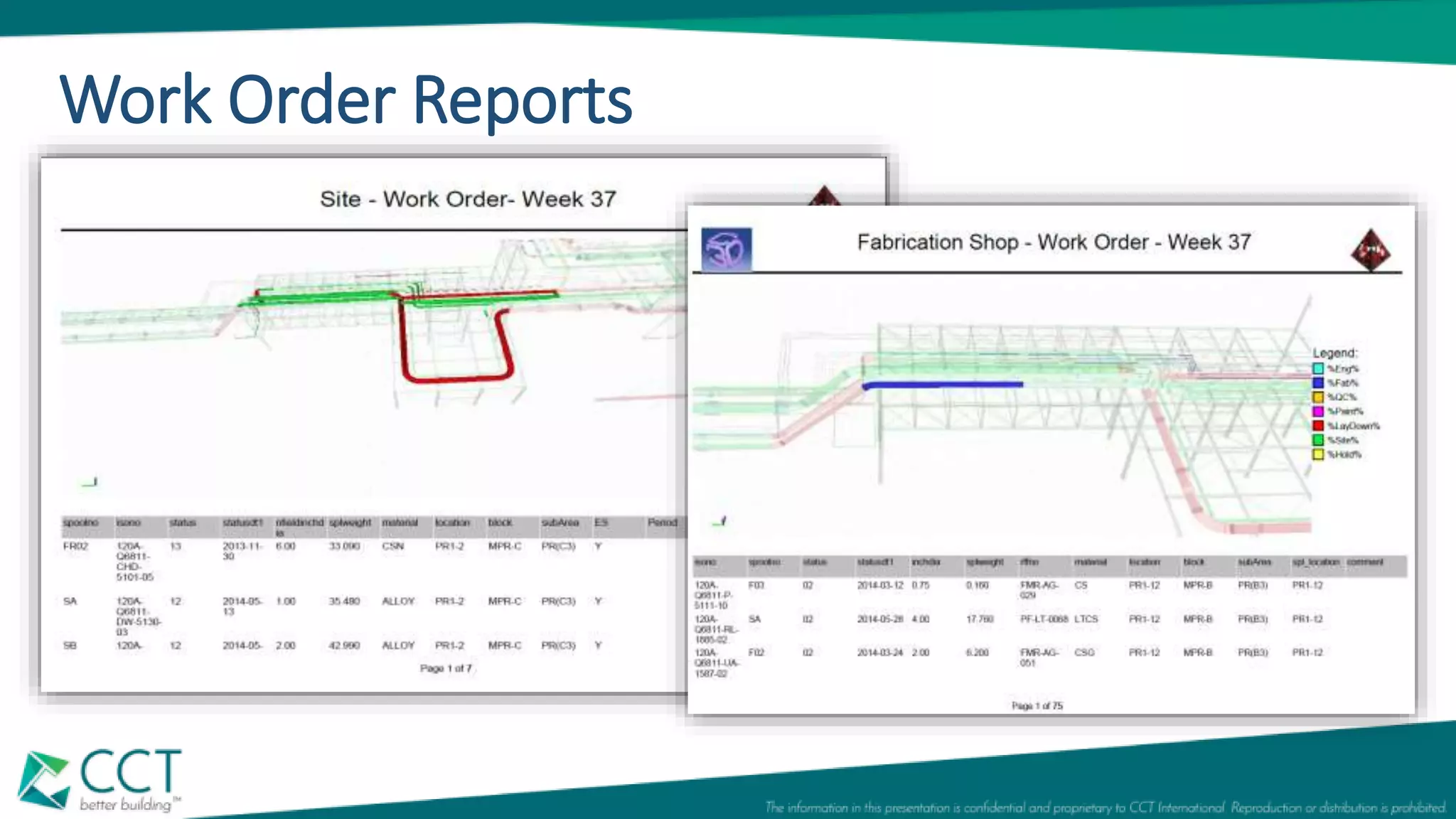

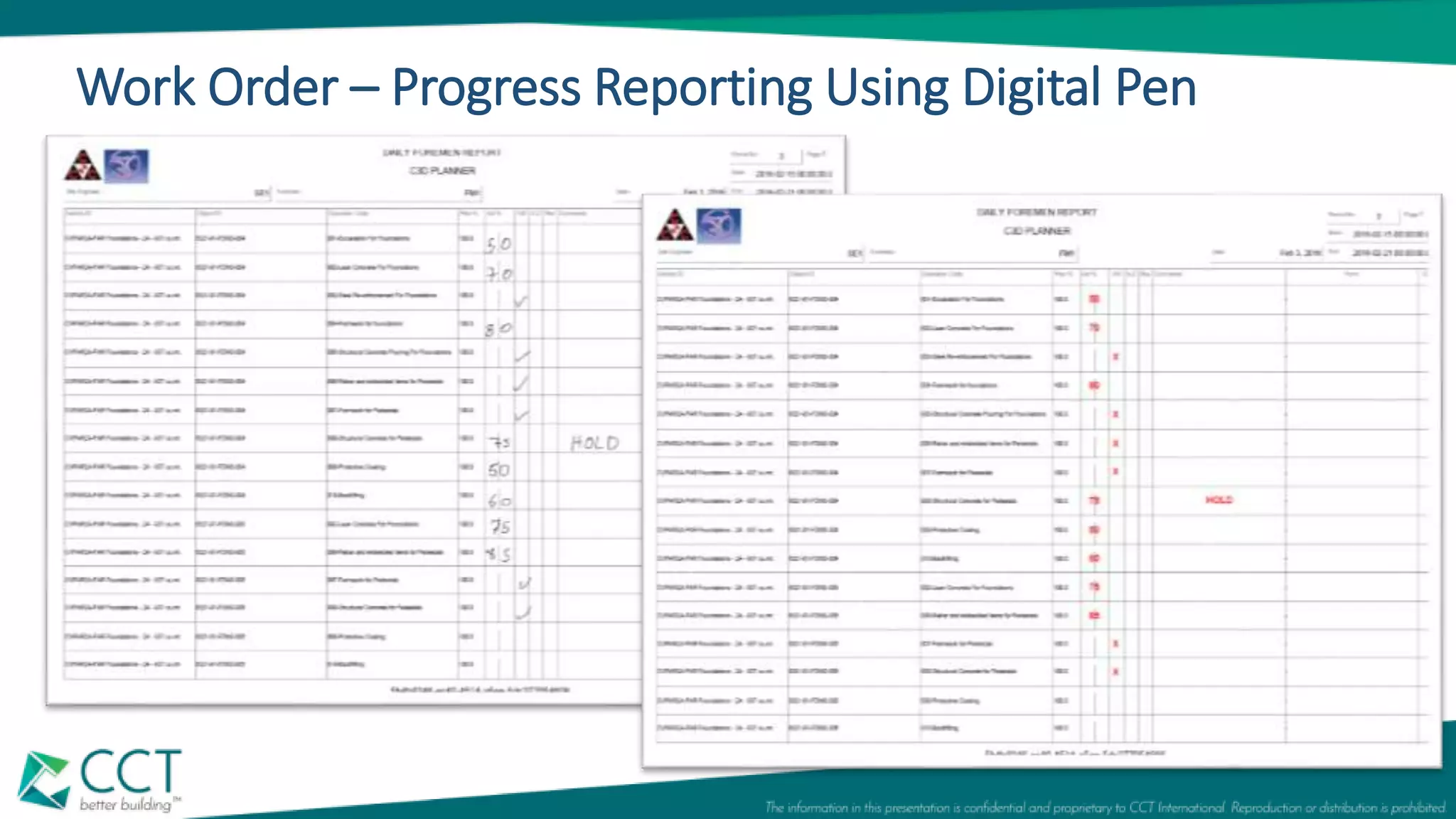

The document discusses the use of c3d®, a BIM-based project control tool, to enhance compliance among site execution teams in construction projects. It outlines various aspects of construction management including project planning, scope definition, and the importance of detailed work breakdown structures. The emphasis is on integrating construction data to improve efficiency and ensure that work orders align with approved scopes.