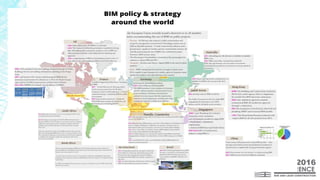

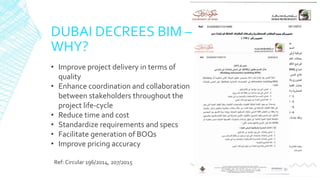

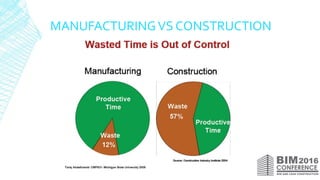

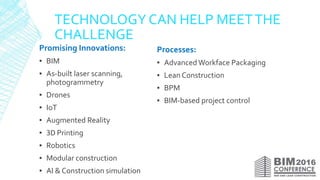

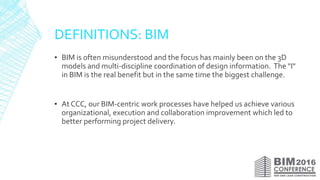

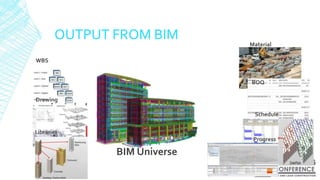

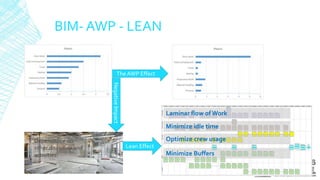

The document discusses the implementation of Building Information Modeling (BIM) in Dubai's construction industry, highlighting its benefits in improving project delivery, coordination, and reducing costs. Key innovations like drones, AI, and lean construction methodologies are emphasized as tools for enhancing efficiency. The conference focused on BIM-based project controls, advanced work packaging, and the importance of collaboration and structured data in successful construction management.