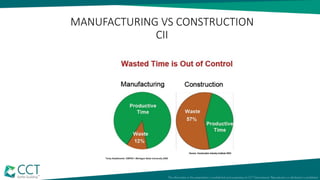

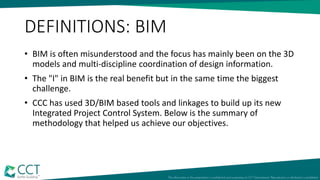

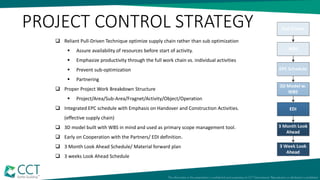

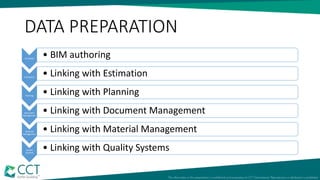

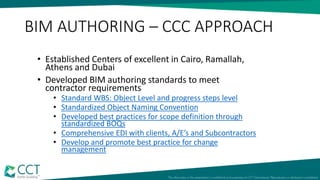

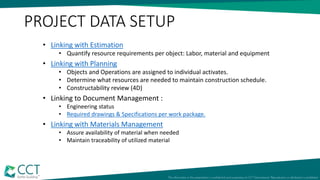

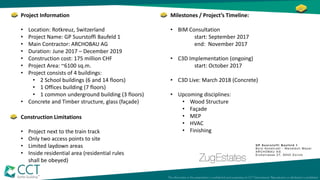

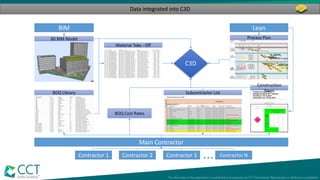

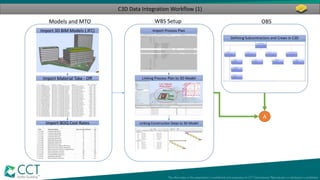

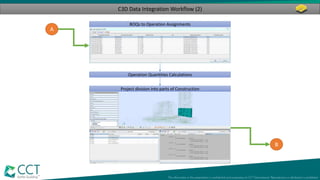

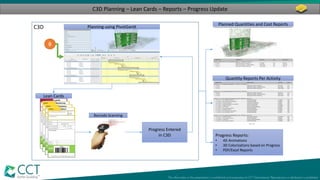

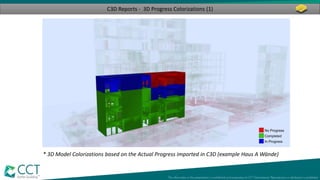

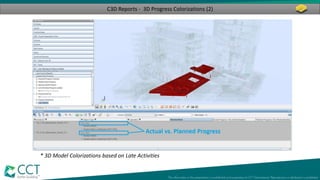

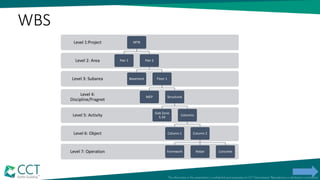

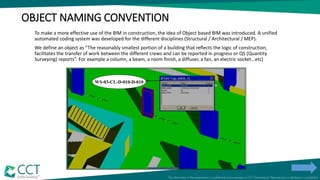

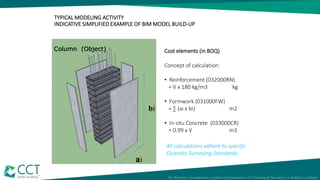

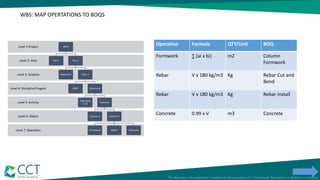

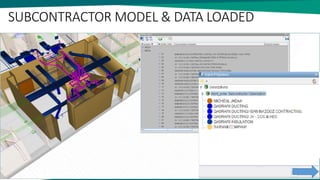

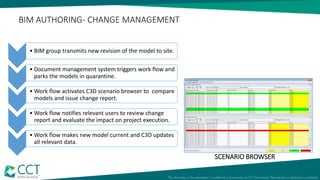

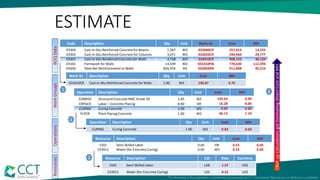

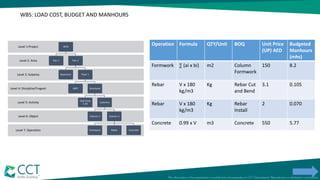

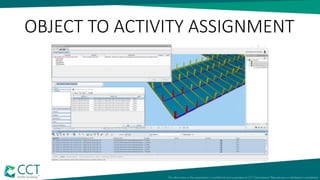

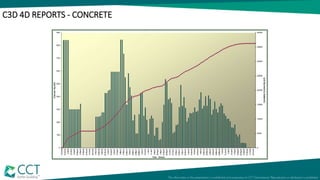

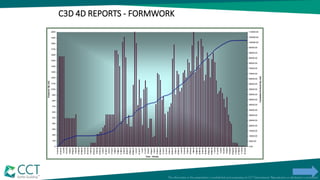

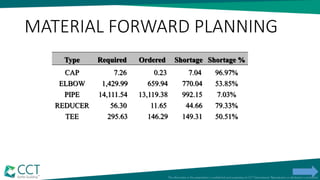

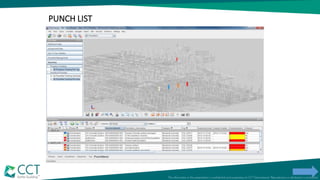

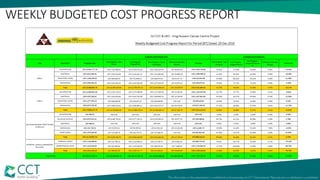

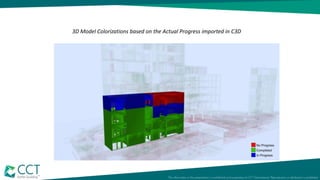

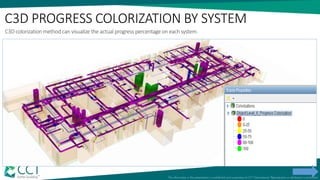

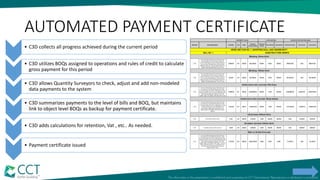

This document discusses using BIM and an integrated project control system to improve construction project controls. It defines BIM and outlines CCC's approach, which links 3D models, estimating, planning, document management, materials management, and quality systems. The methodology uses object-based modeling, work breakdown structures, integrated schedules, early partnering, look-ahead planning, and links data between functions like estimating and planning. It provides examples of model authoring standards, naming conventions, estimating against models, assigning operations to activities, and generating 4D reports and progress visualizations to improve project controls using an integrated BIM-based approach.