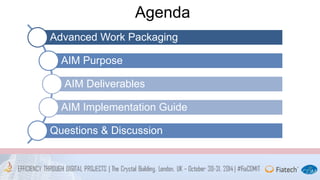

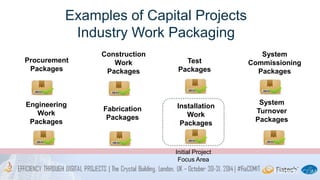

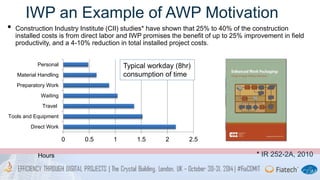

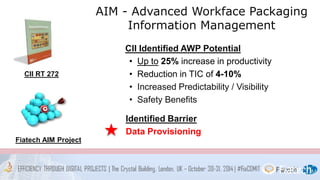

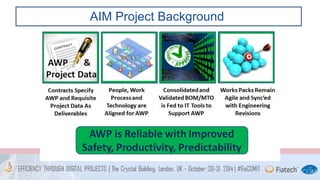

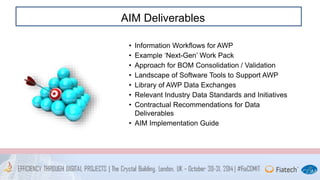

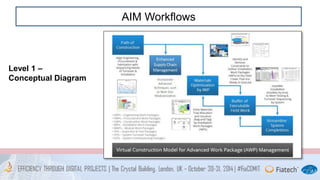

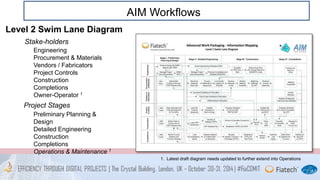

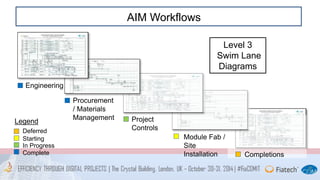

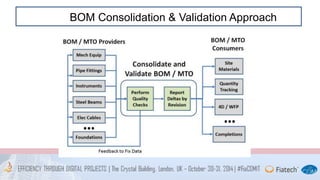

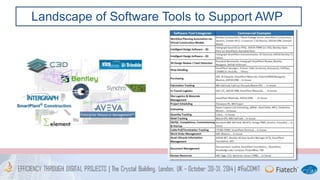

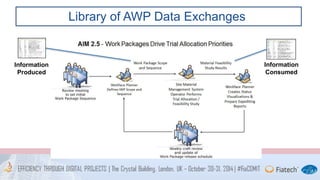

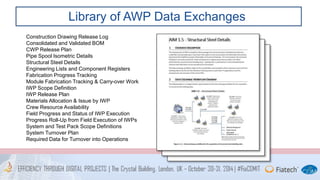

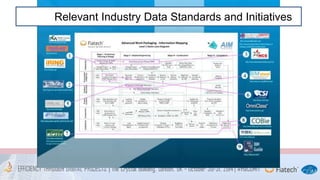

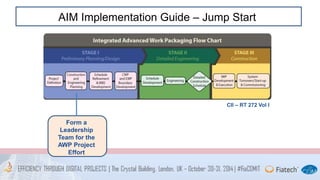

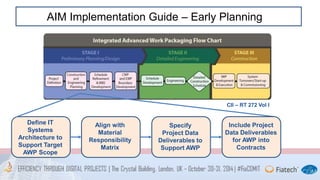

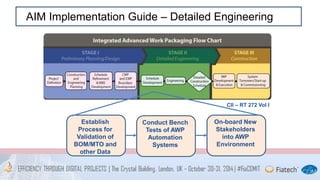

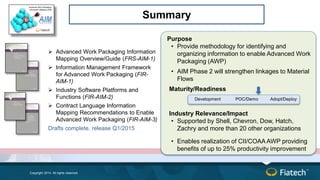

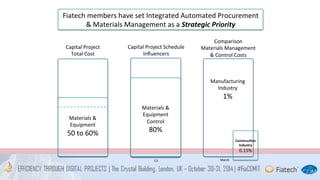

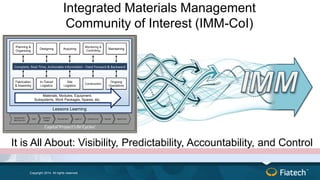

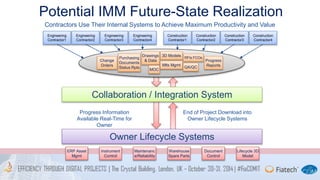

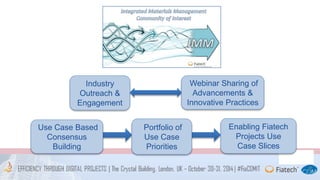

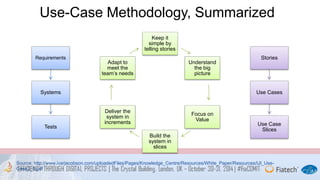

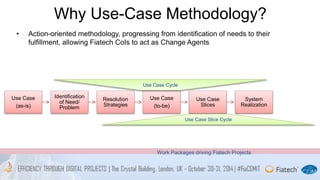

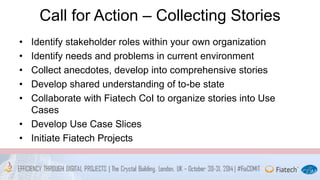

This document discusses Advanced Work Packaging Information Mapping (AIM), a project aimed at developing methods and tools to enable effective Advanced Work Packaging (AWP) in capital projects. The document outlines the AIM project deliverables which include information workflows for AWP, example work packages, approaches for bill of materials consolidation and validation, relevant software tools and data standards, contractual recommendations, and an implementation guide. It also discusses the potential benefits of AWP including up to 25% increased productivity and 4-10% reduction in total installed costs. Finally, the document promotes the use of use case methodology to further the goals of the Integrated Materials Management Community of Interest.