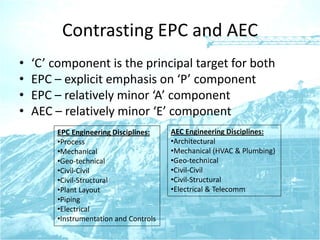

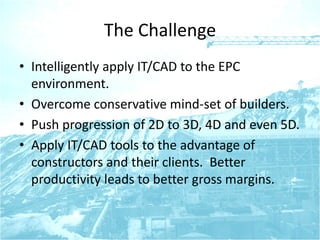

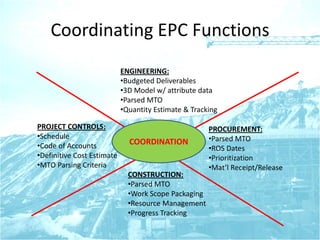

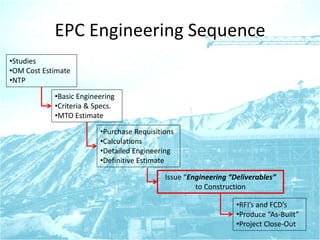

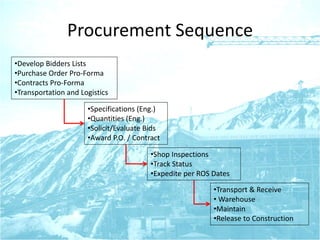

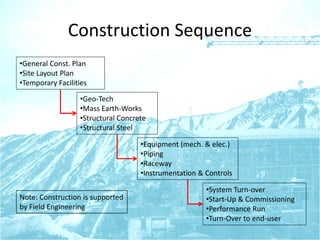

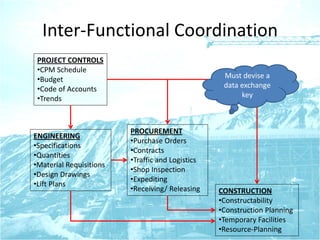

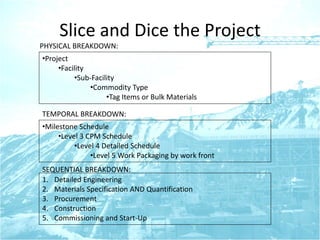

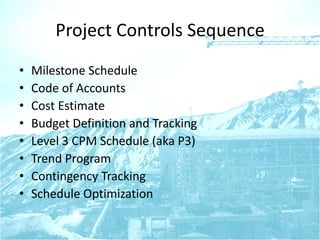

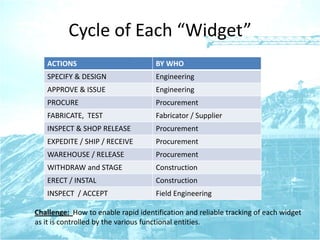

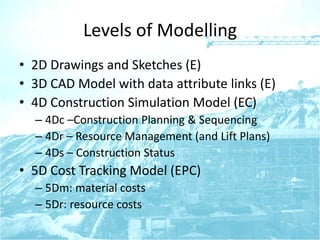

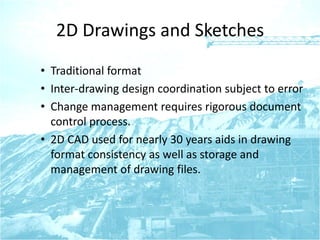

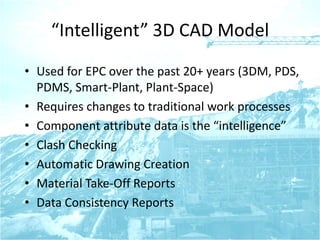

This document discusses engineering, procurement, and construction (EPC) projects and opportunities for improvement through automation. It provides an overview of EPC project challenges, contrasts EPC and architecture, engineering, and construction projects, reviews principal EPC functions and engineering disciplines. It also discusses the evolution of CAD use, levels of modeling including 2D, 3D, 4D, and 5D, and provides a case study of a $2.5 billion EPC copper concentrator plant project in Chile. The document proposes using a work execution package matrix to coordinate material management across spatial divisions and commodity types.