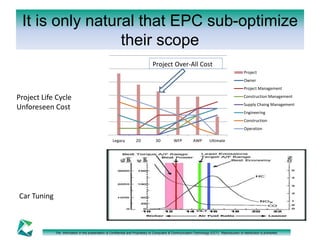

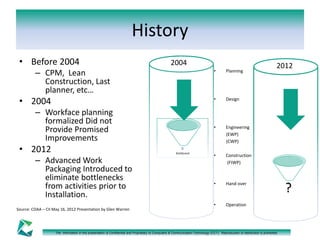

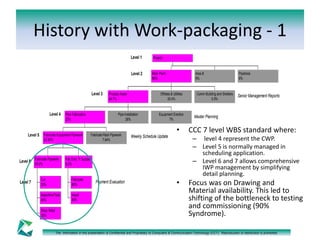

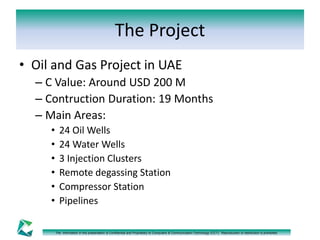

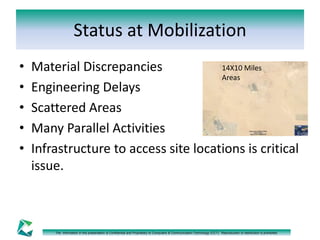

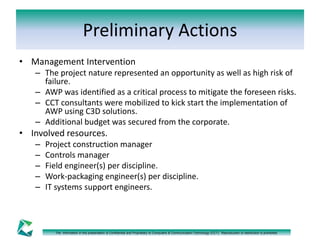

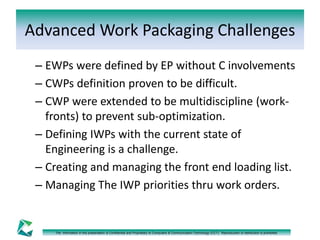

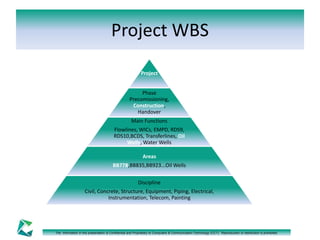

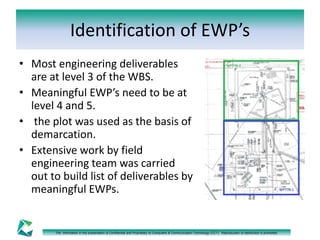

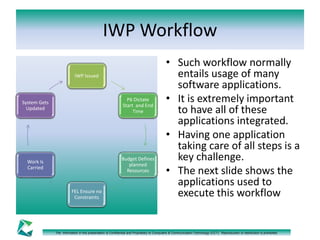

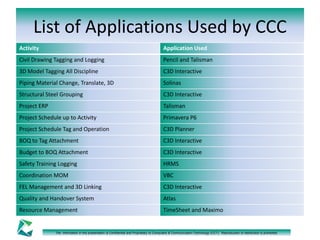

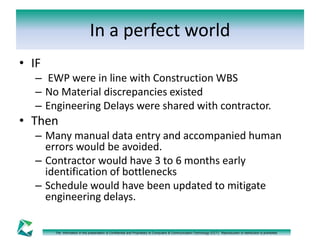

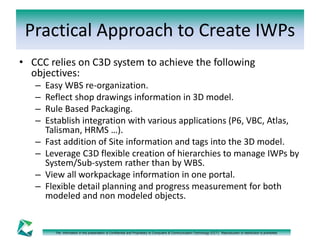

The presentation outlines the implementation of advanced work packaging (AWP) in construction projects, emphasizing its role in optimizing project controls and enhancing efficiency. Key achievements from previous implementations in various projects are highlighted, showcasing significant improvements in productivity and reductions in construction delays and defects. Challenges related to coordination, data management, and cultural shifts within construction teams are also discussed, alongside the ongoing efforts to integrate advanced technologies for better project outcomes.