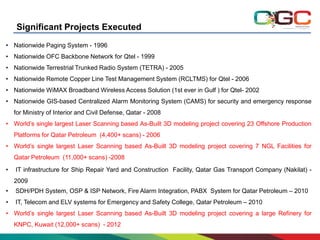

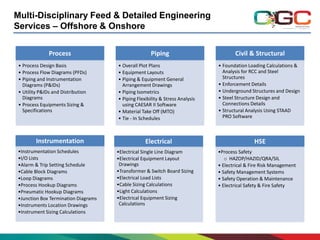

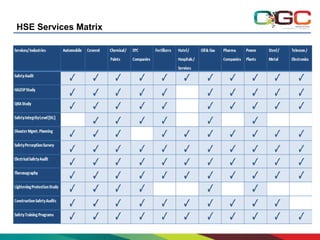

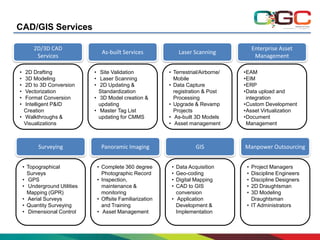

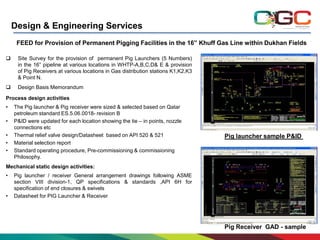

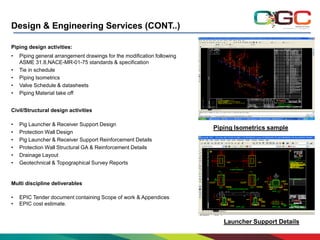

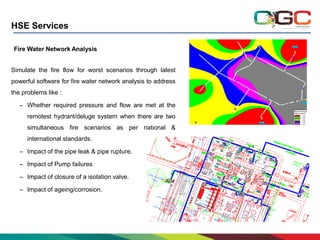

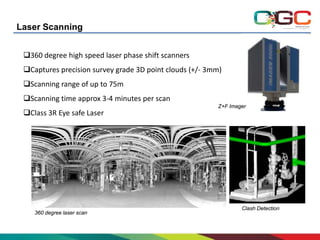

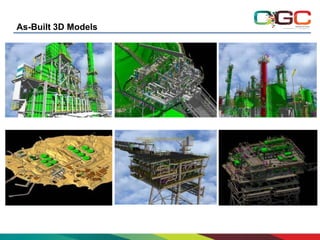

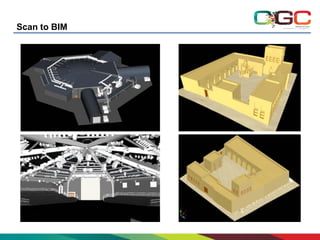

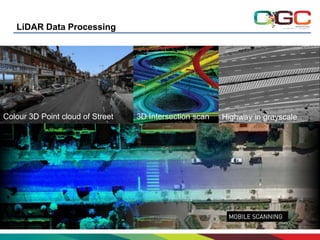

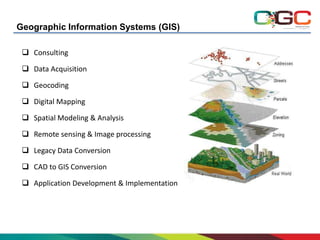

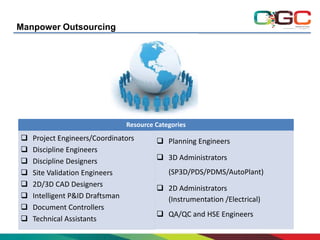

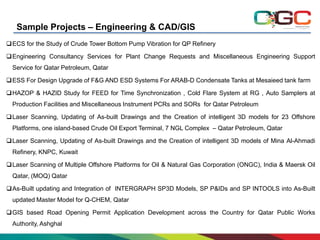

Consolidated Gulf Company is a 190 million USD conglomerate providing technology and engineering solutions across several industries. It has over 600 employees and offices in multiple countries. Some of its notable past projects include laser scanning of oil and gas facilities for Qatar Petroleum and KNPC of Kuwait. It offers multi-disciplinary engineering services including process, piping, civil, electrical and instrumentation design. It is also expert in laser scanning, BIM, GIS and manpower outsourcing.