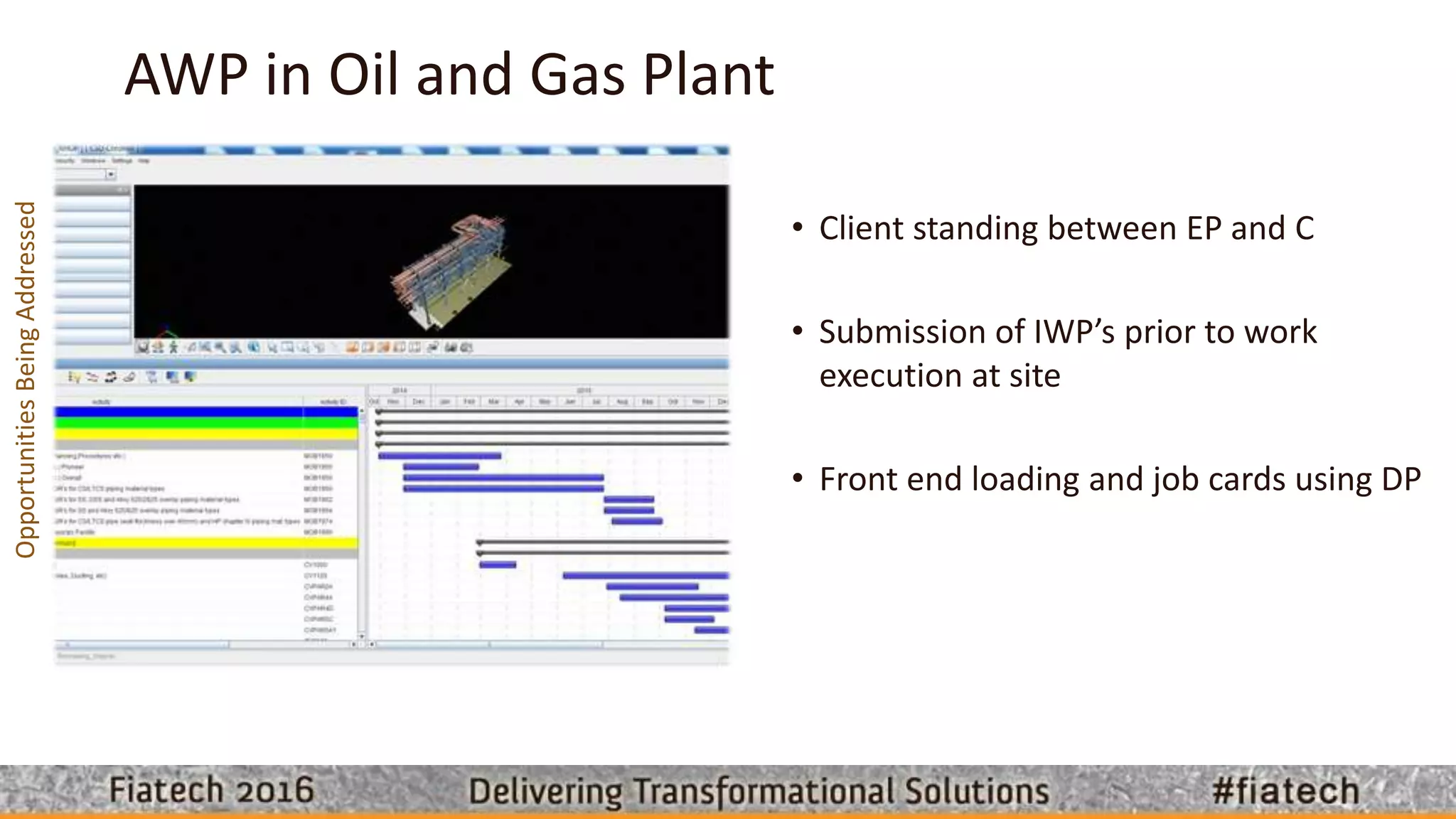

This document discusses advanced work packaging (AWP) in oil and gas plant projects. It provides examples of how AWP was implemented in the Rabab Harweel Integrated Project (RHIP) in Oman, including defining work fronts and installation work packages, front-end loading, and developing a workflow using BIM tools. The benefits realized from using AWP in RHIP included improved forecasting of manpower needs, increased crew productivity, and submission of installation work packages before planned start dates. Future applications of AWP are also discussed.