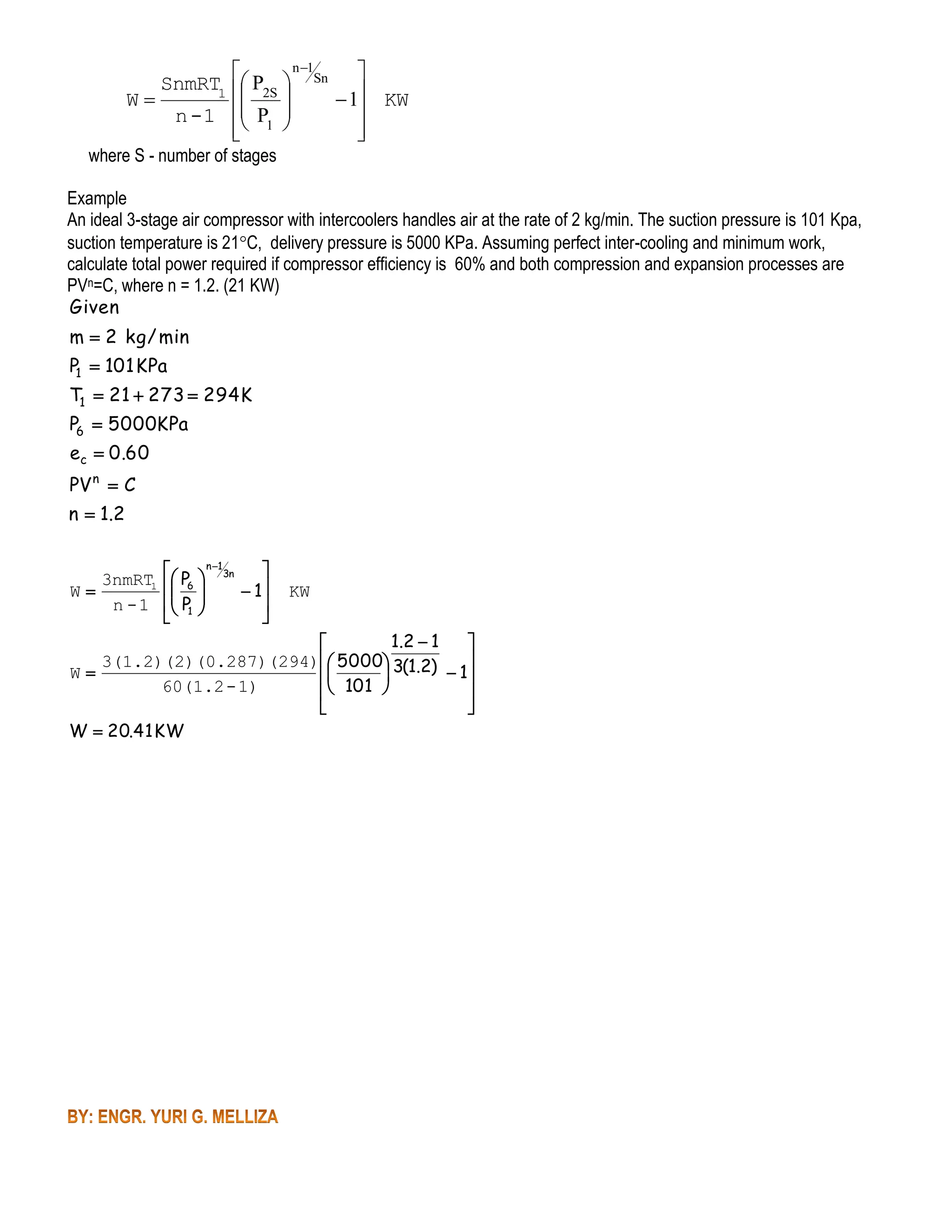

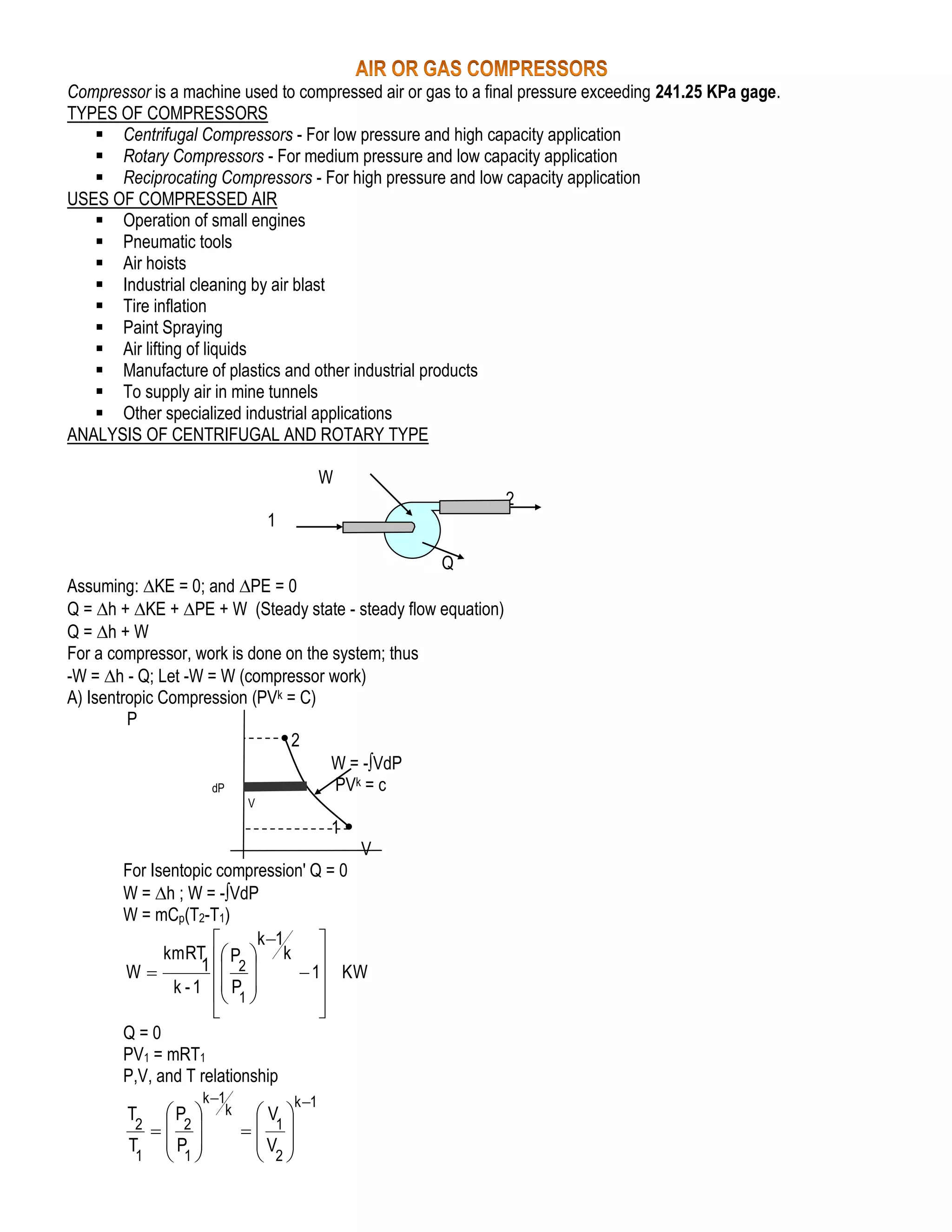

A compressor is a machine that compresses air or gas to pressures over 241.25 KPa. There are three main types: centrifugal for low pressure/high capacity, rotary for medium pressure/low capacity, and reciprocating for high pressure/low capacity. Compressed air has many industrial and specialized uses. Compressors can be analyzed using the steady flow energy equation and isentropic, polytropic, or isothermal processes. Multistage compression saves power by cooling the air between stages to limit temperature and pressure increases.

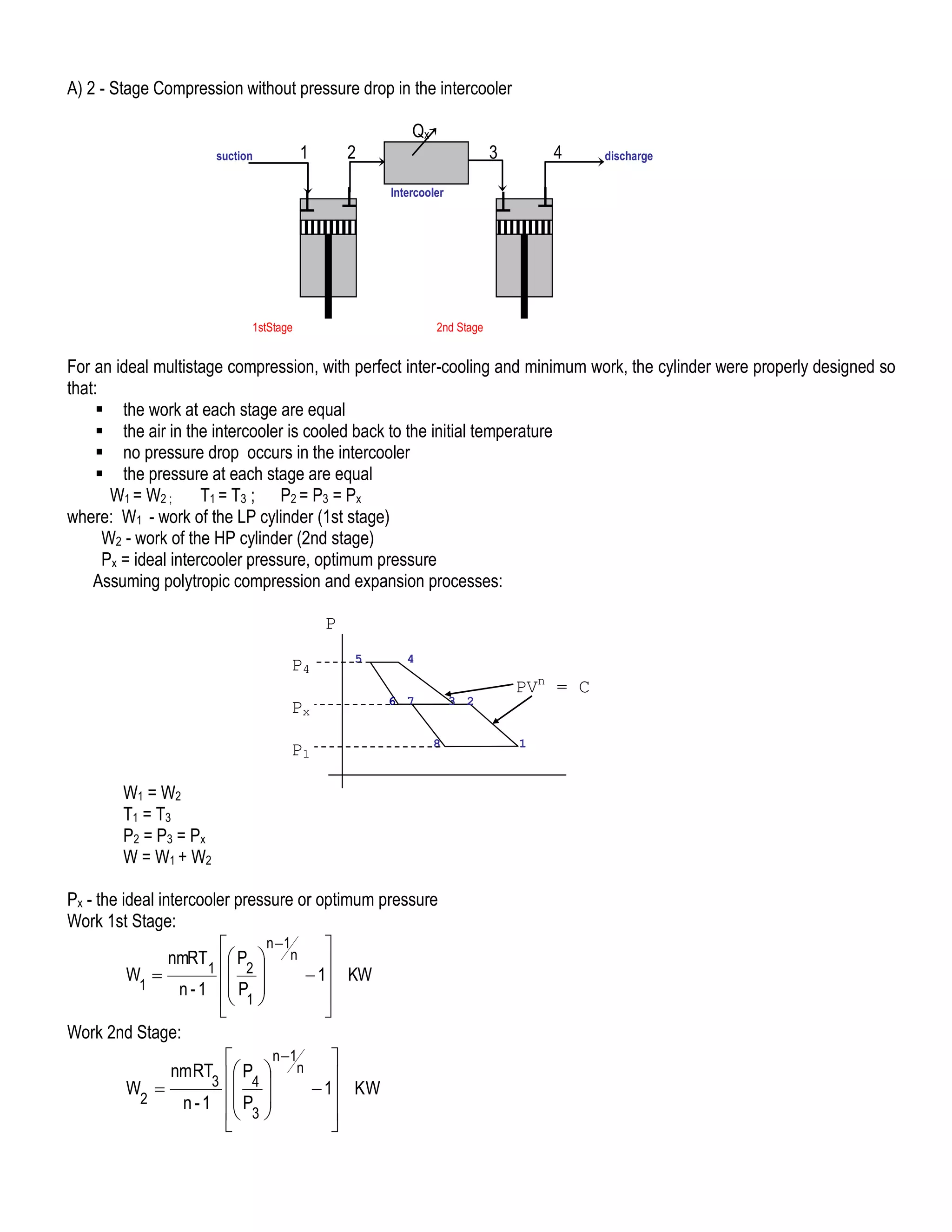

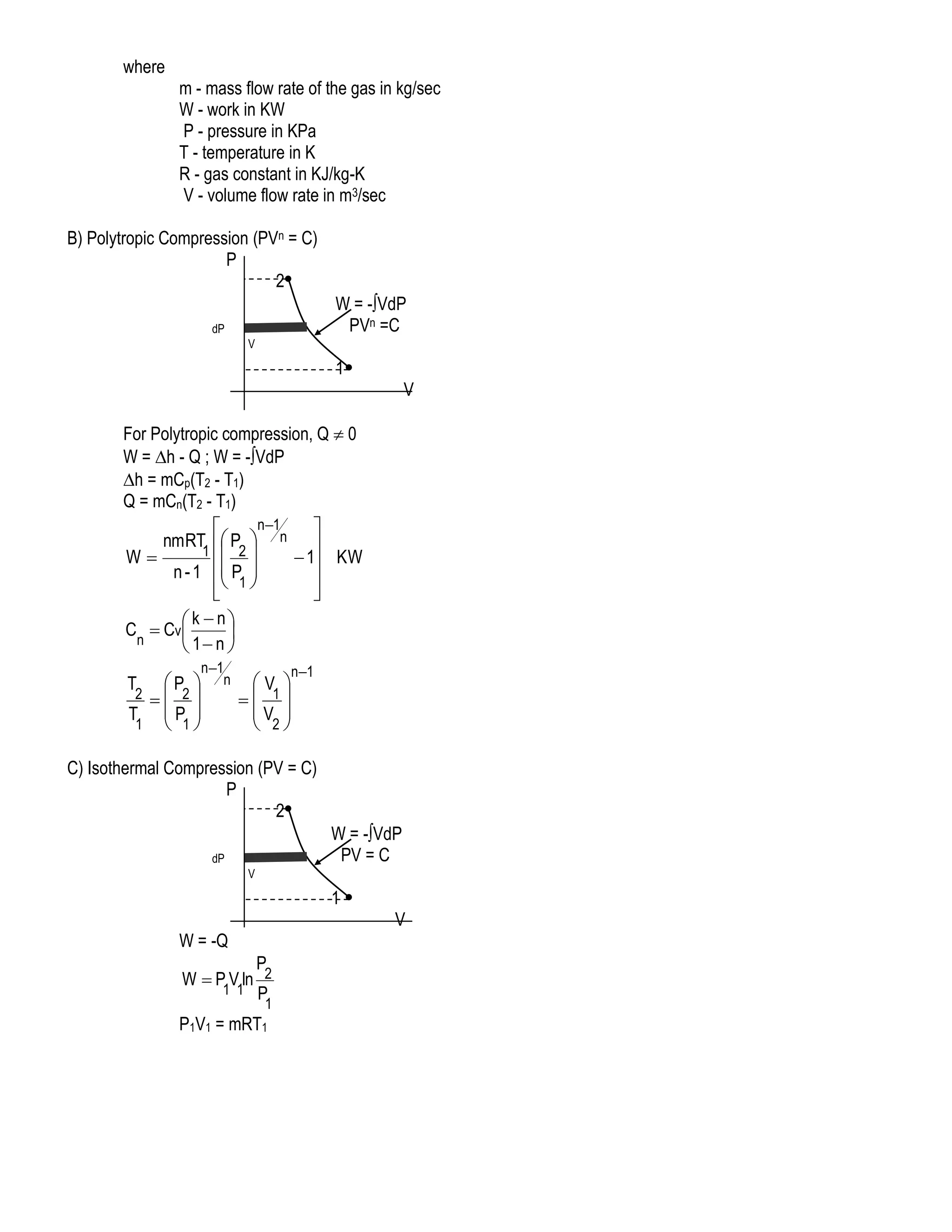

![DISPLACEMENT VOLUME

A) For single acting

VD = LD2Nn' m3/sec

4(60)

B) For Double acting without considering the volume of piston rod

VD = 2LD2Nn' m3/sec

4(60)

C) For Double acting considering volume of piston rod

VD = LNn'[2D2 - d2] m3/sec

4(60)

where: L - length of stroke, m

D - diameter of bore, m

d - diameter of piston rod, m

n' - no. of cylinders

ACTUAL VOLUMETRIC EFFICIENCY

V

ηva a x 100 %

VD

Va - actual volume of air or gas drawn in

MEAN EFFECTIVE PRESSURE

W

Pm

KPa

VD

W in KJ, KJ/kg, KW

VD in m3, m3/kg, m3/sec

PISTON SPEED

PS = 2LN m/min

PS = 2LN m/sec

60

EFFICIENCY

A) COMPRESSION EFFICIENCY

cn = Ideal Work

x 100%

Indicated Work

B) MECHANICAL EFFICIENCY

m = Indicated Work x 100%

Brake Work

C) COMPRESSOR EFFICIENCY

c = cn = m = Ideal Work x 100%

Brake work

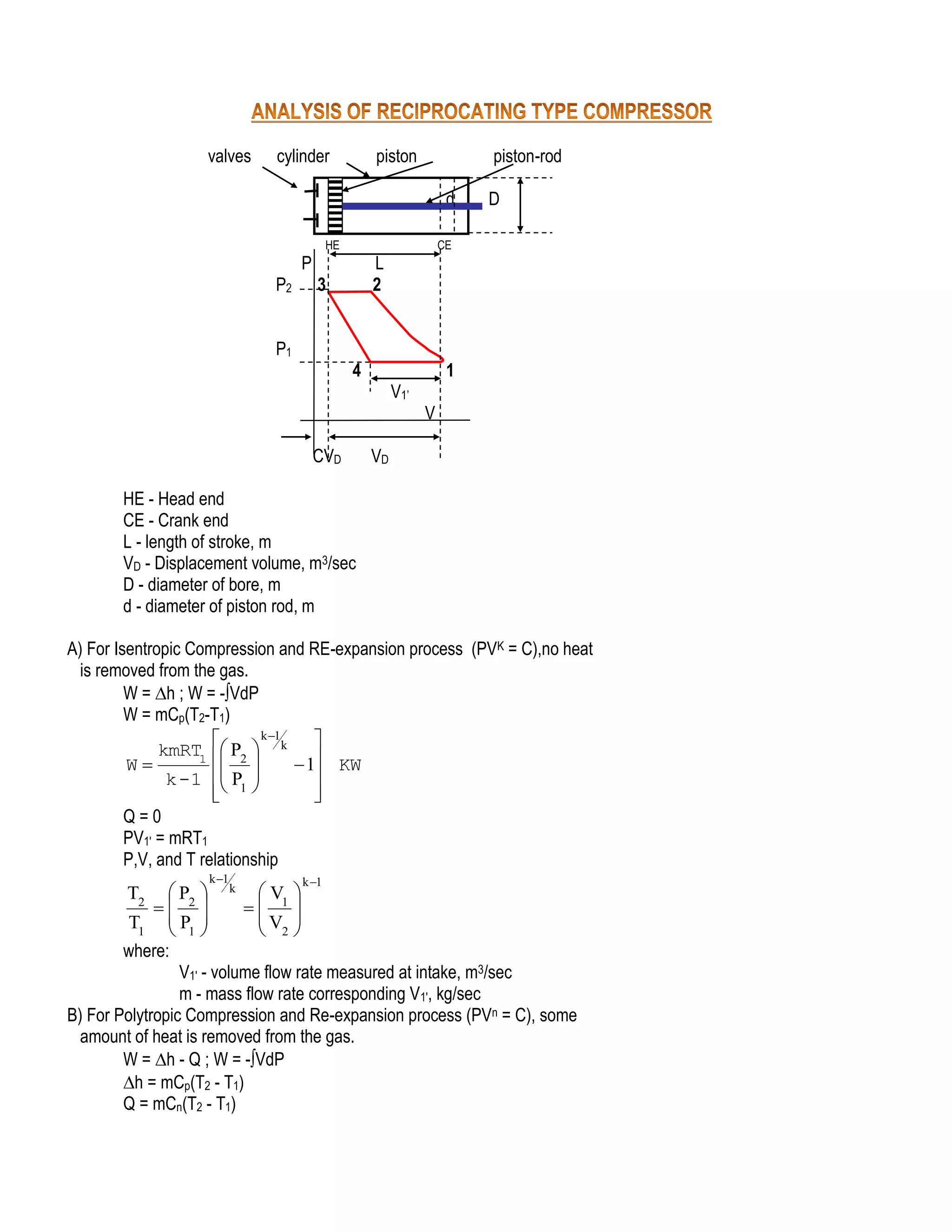

MULTISTAGE COMPRESSION

Multi staging is simply the compression of air or gas in two or more cylinders in place of a single cylinder compressor. It is

used in reciprocating compressors when pressure of 300 KPa and above are desired, in order to:

Save power

Limit the gas discharge temperature

Limit the pressure differential per cylinder

Prevent vaporization of lubricating oil and to prevent its ignition if the temperature becomes too high.

It is common practice for multi-staging to cool the air or gas between stages of compression in an intercooler, and it is this

cooling that affects considerable saving in power.](https://image.slidesharecdn.com/notesoncompressor-140208205915-phpapp02/75/LECTURE-Notes-on-compressor-5-2048.jpg)