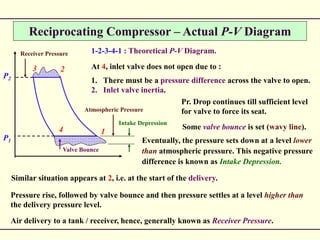

1) A compressor takes in air at atmospheric pressure and compresses it, delivering it at a higher pressure to a storage vessel.

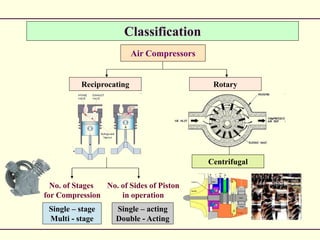

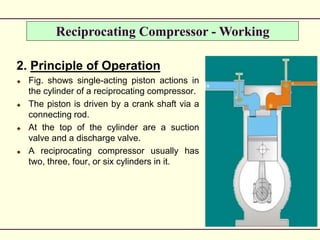

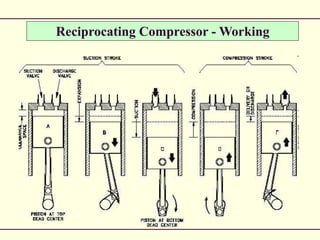

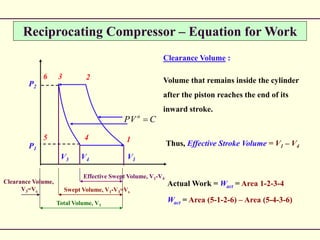

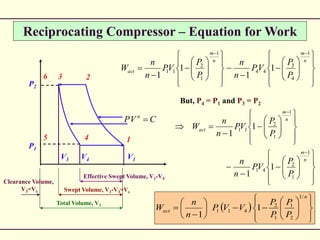

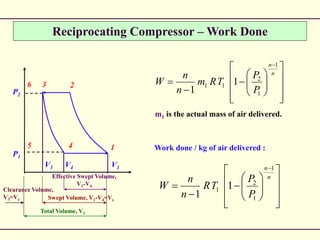

2) Reciprocating compressors use pistons driven by a crankshaft to compress air in cylinders. As the piston moves, the air is compressed and discharged from the cylinder.

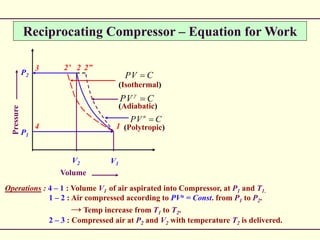

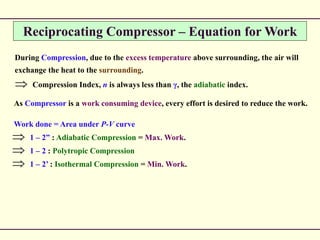

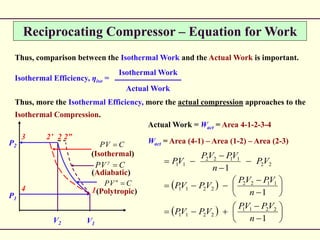

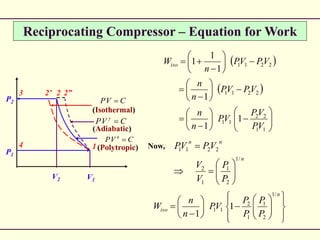

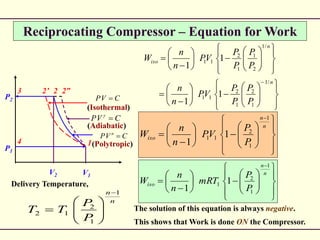

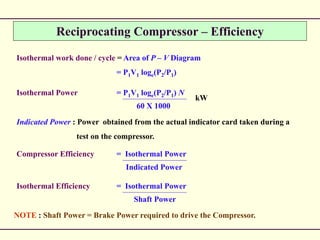

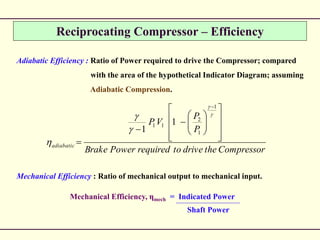

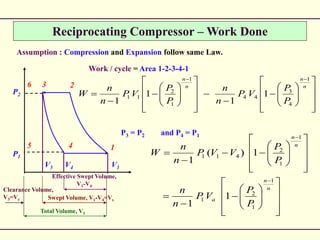

3) The work required to compress air depends on the pressure and volume changes. Actual work done is greater than theoretical isothermal work due to heat transfer during compression.