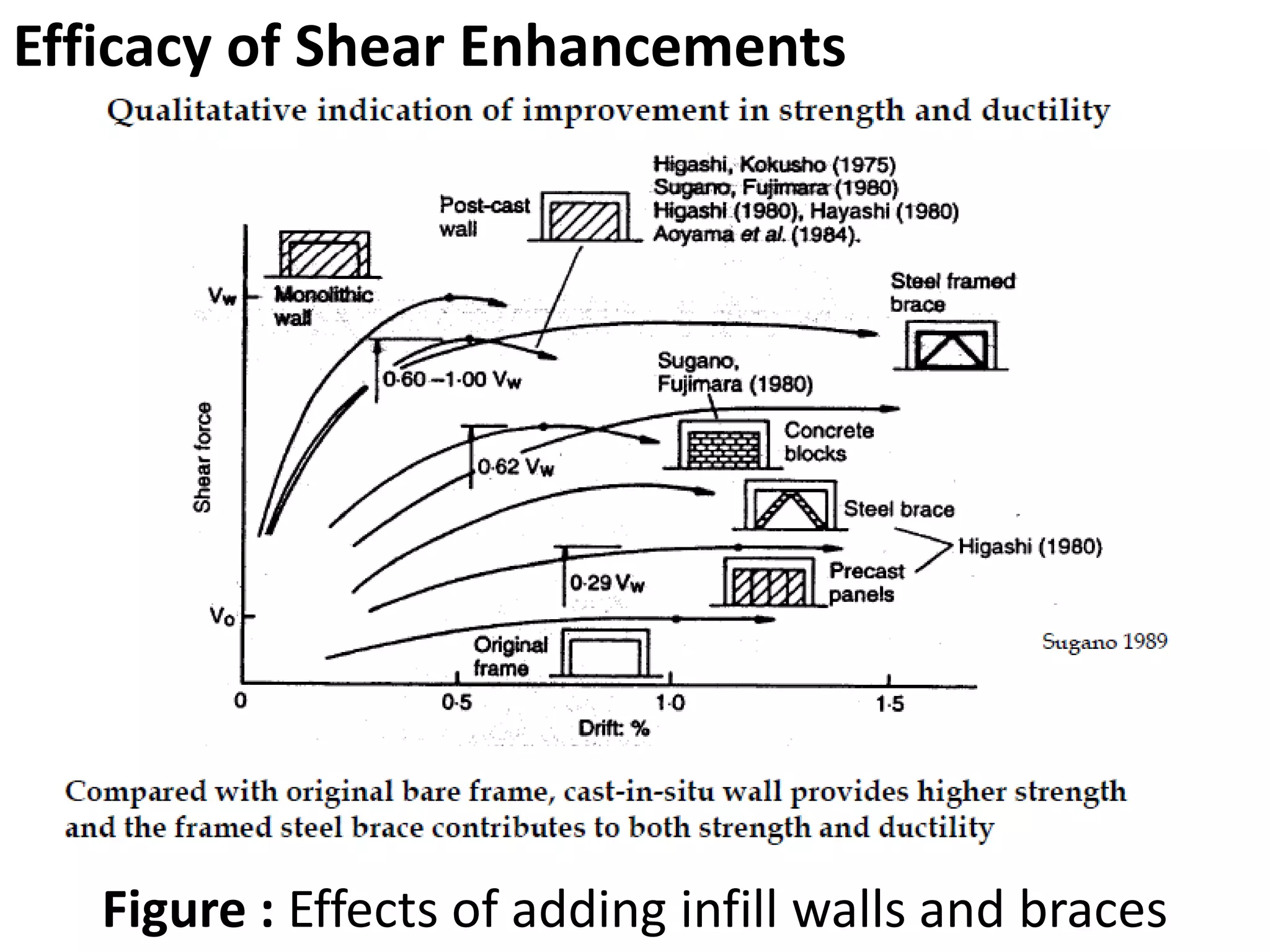

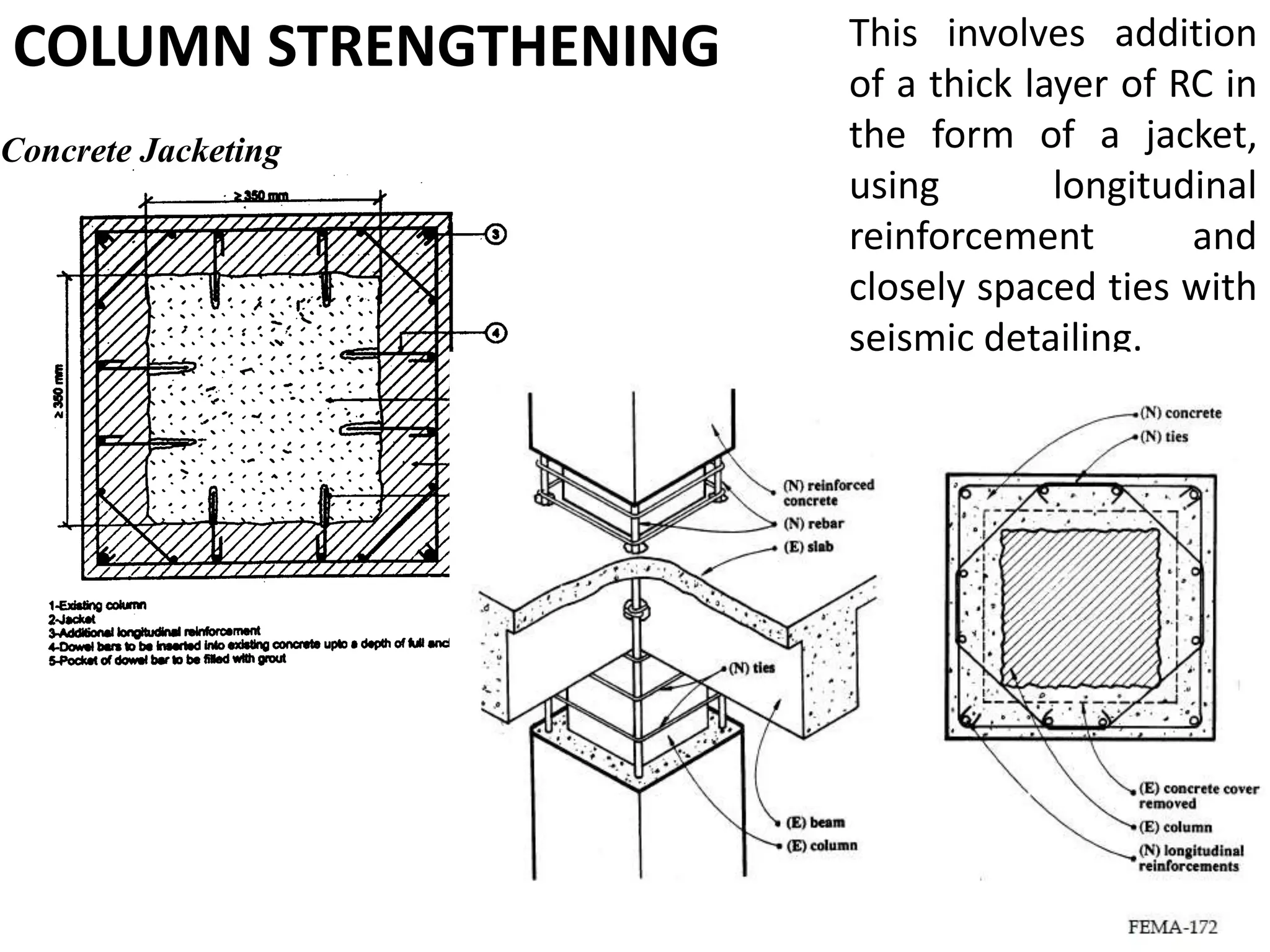

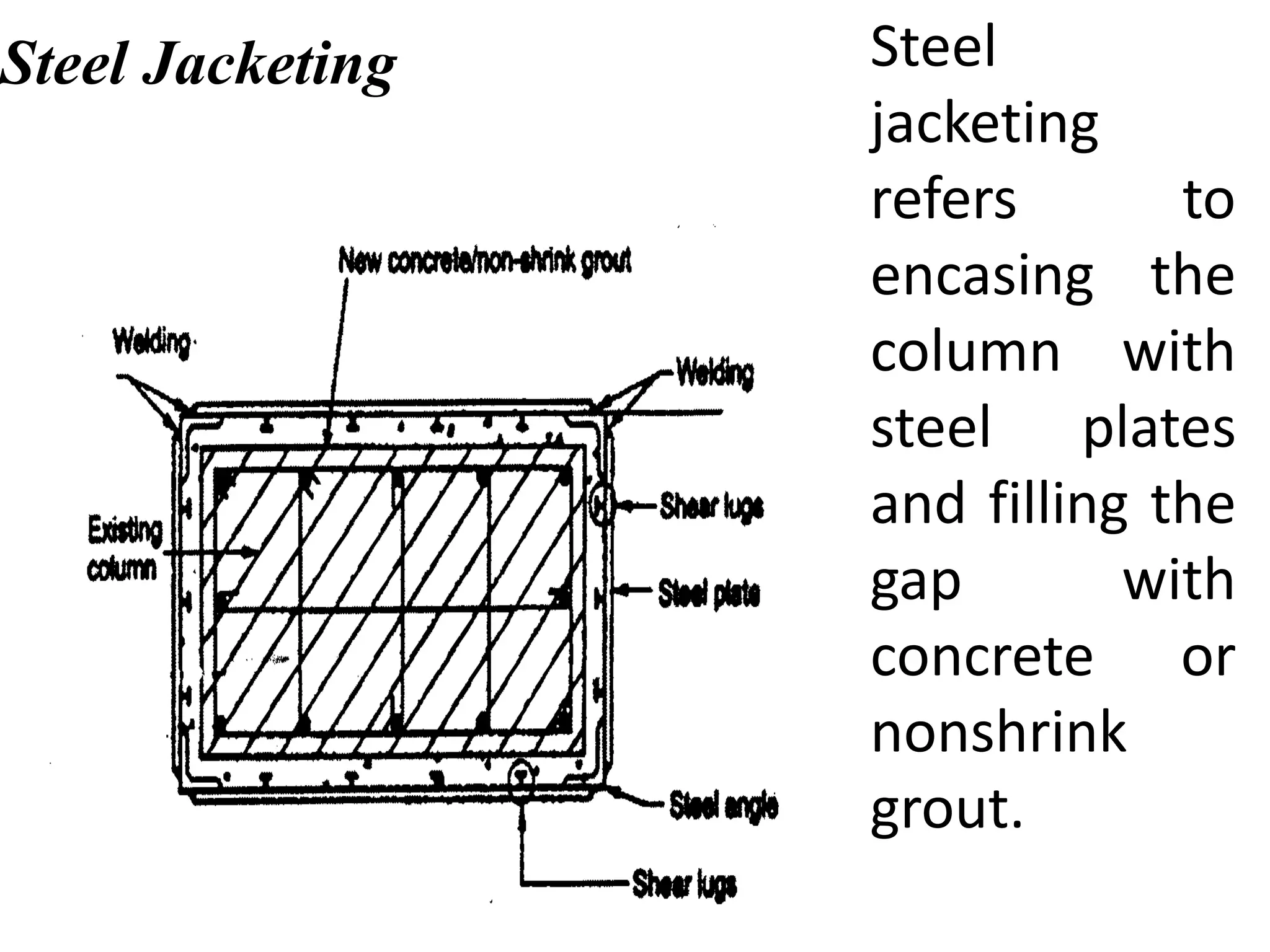

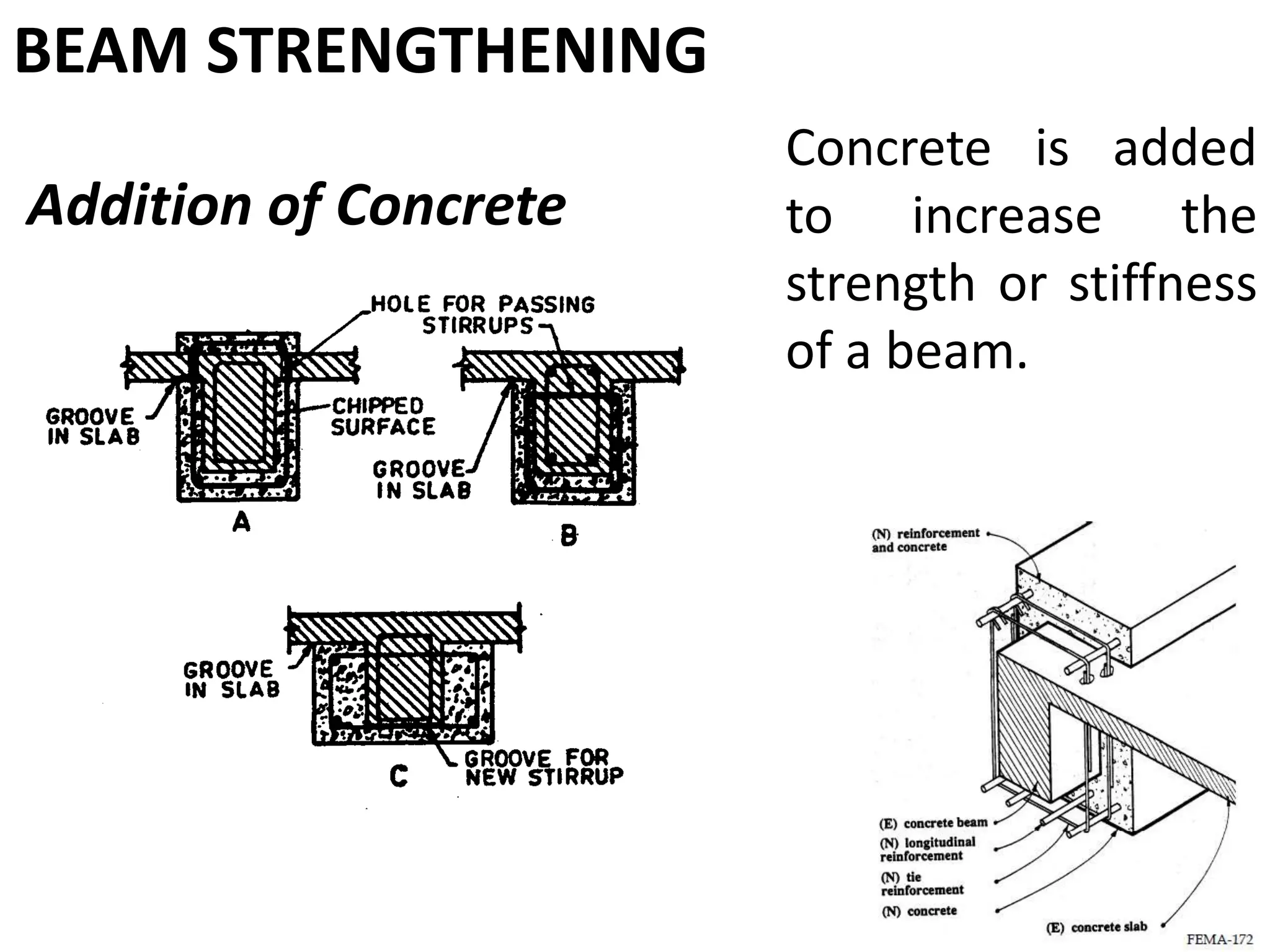

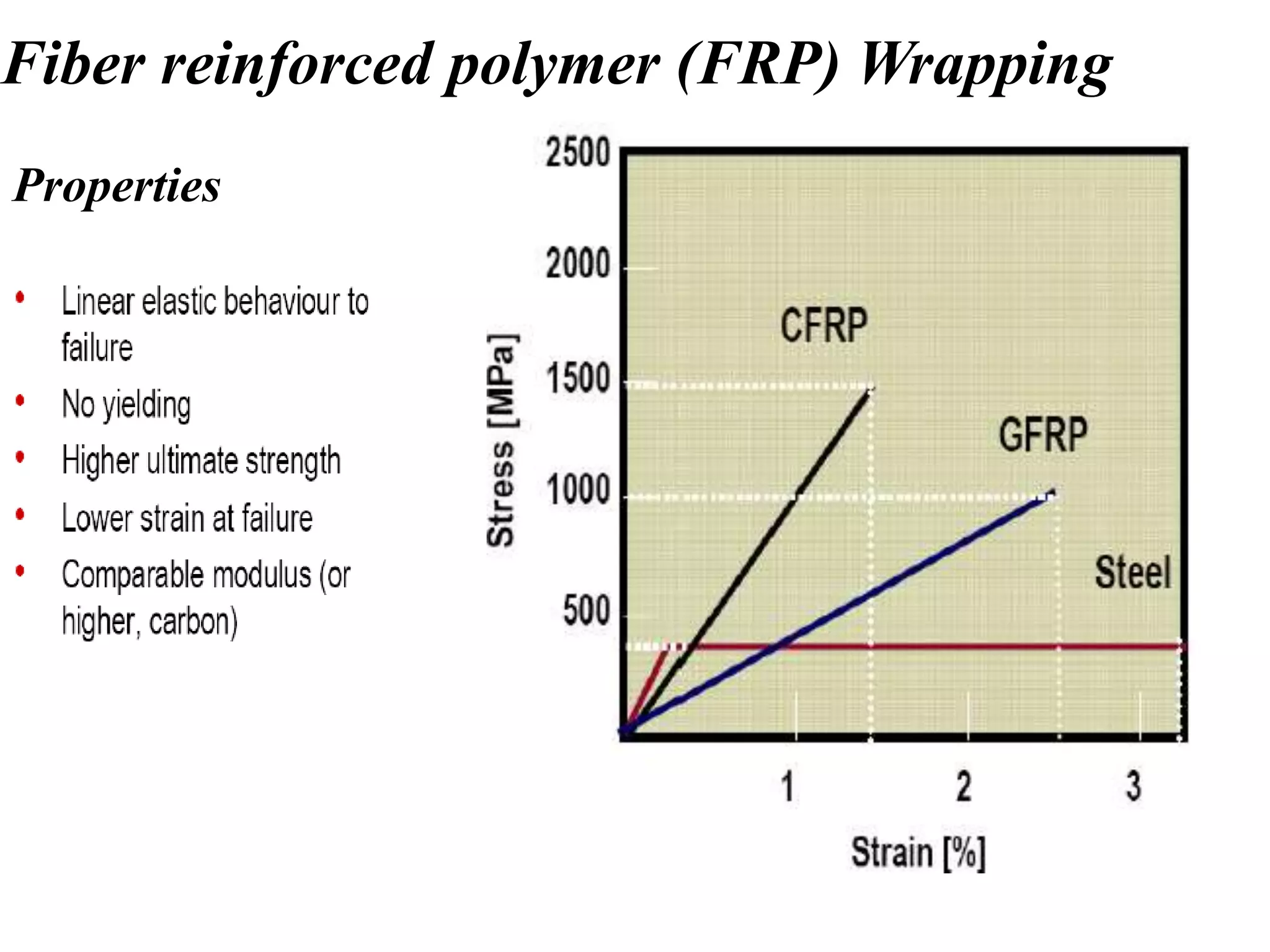

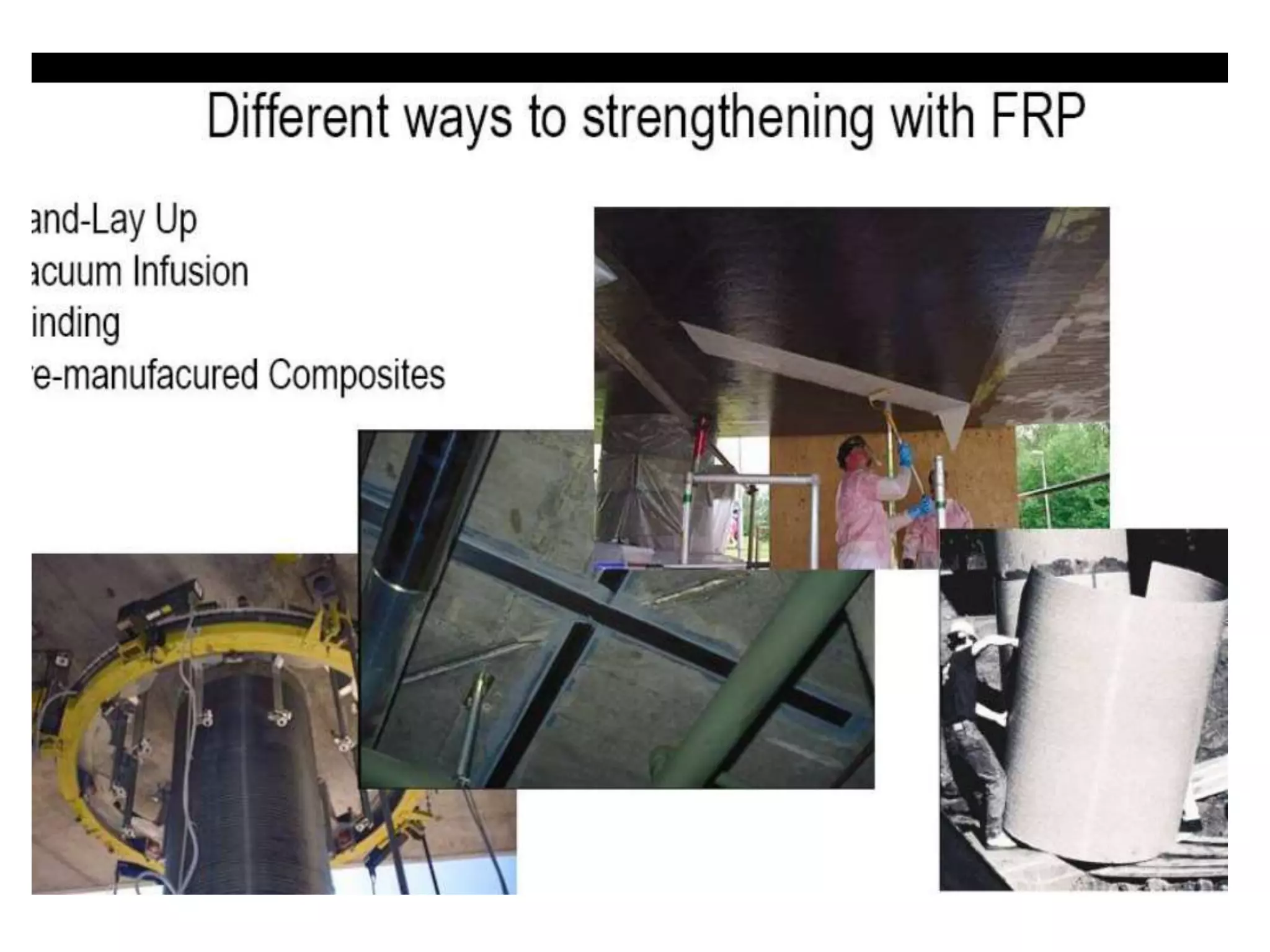

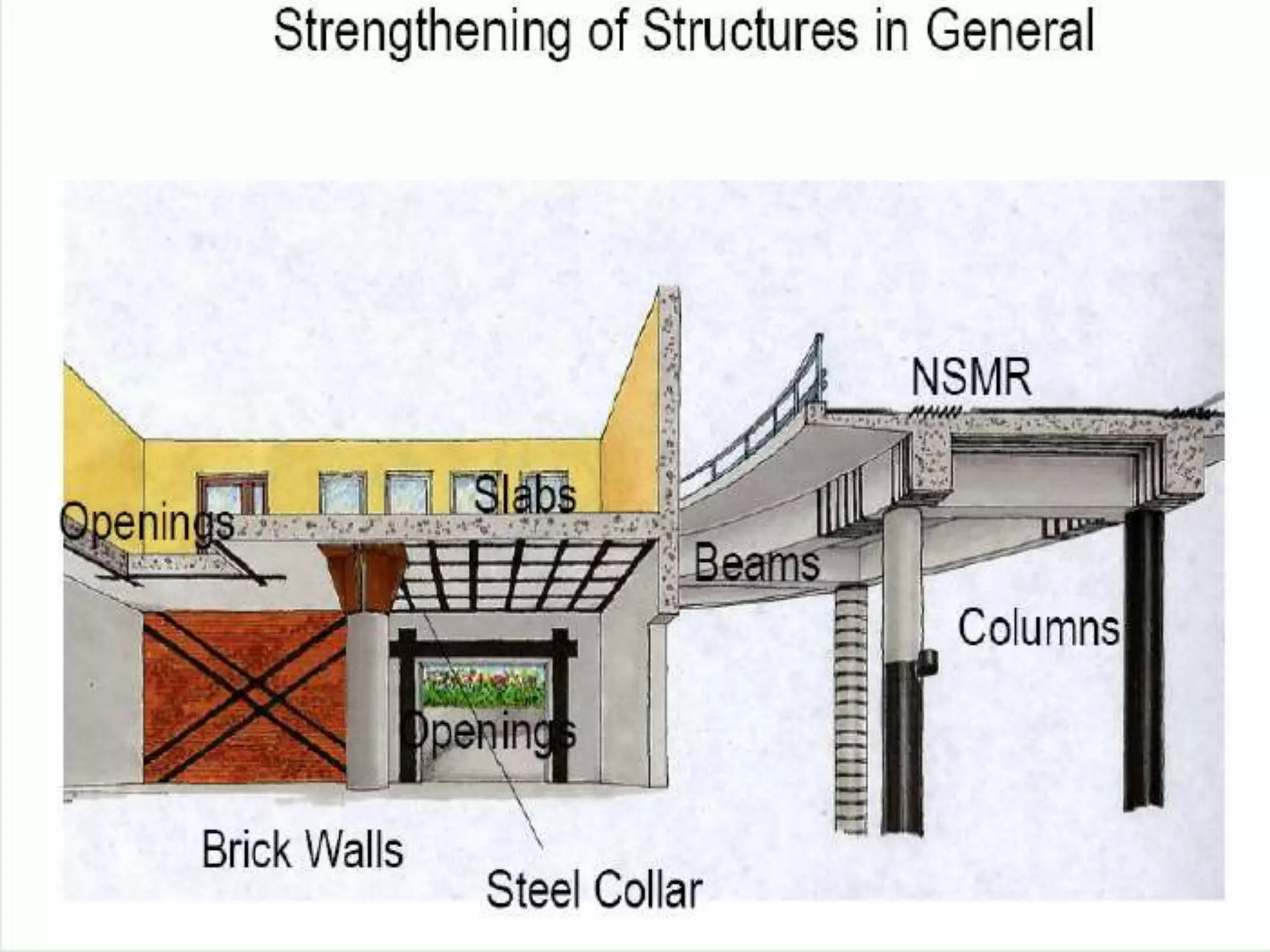

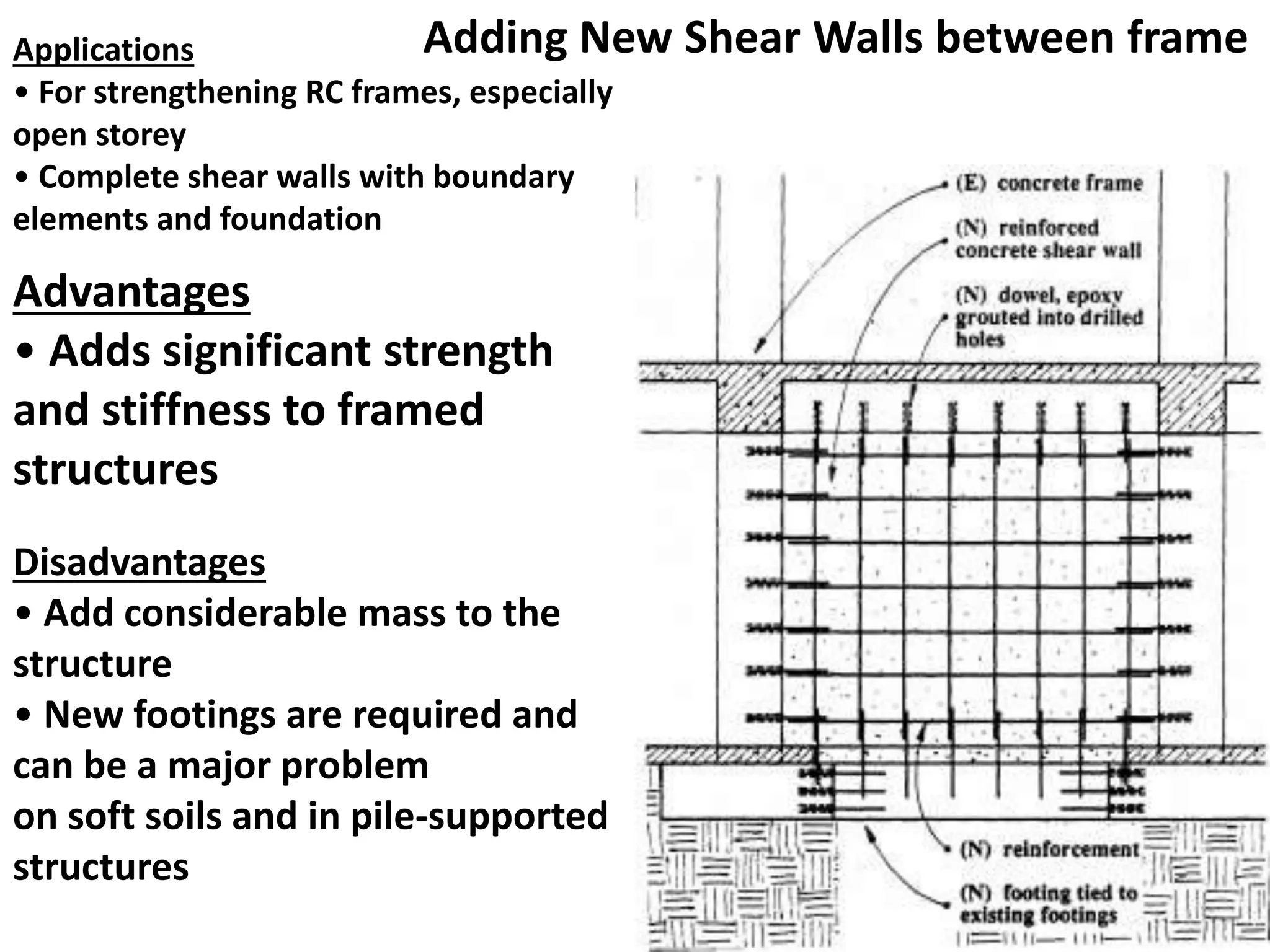

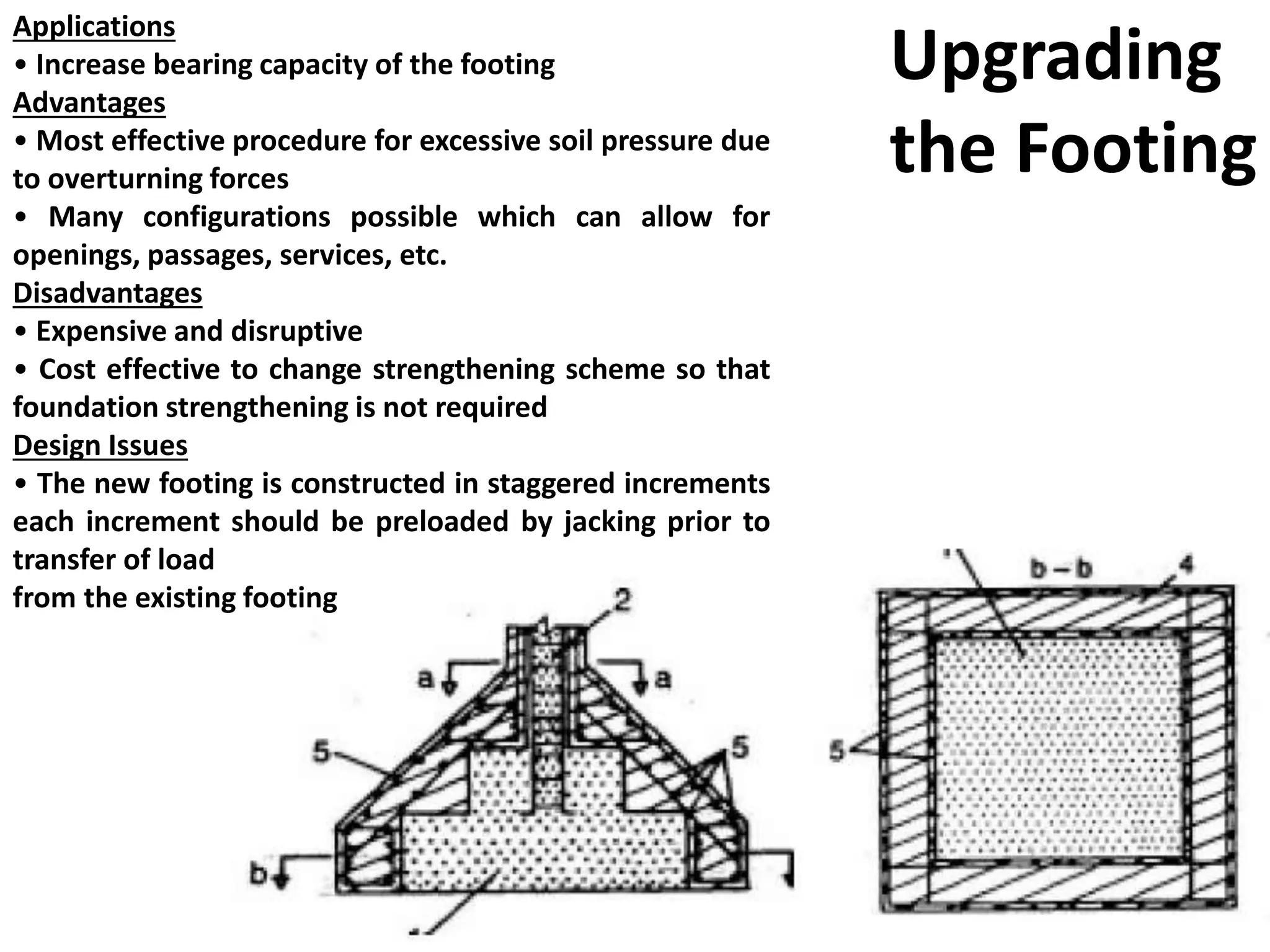

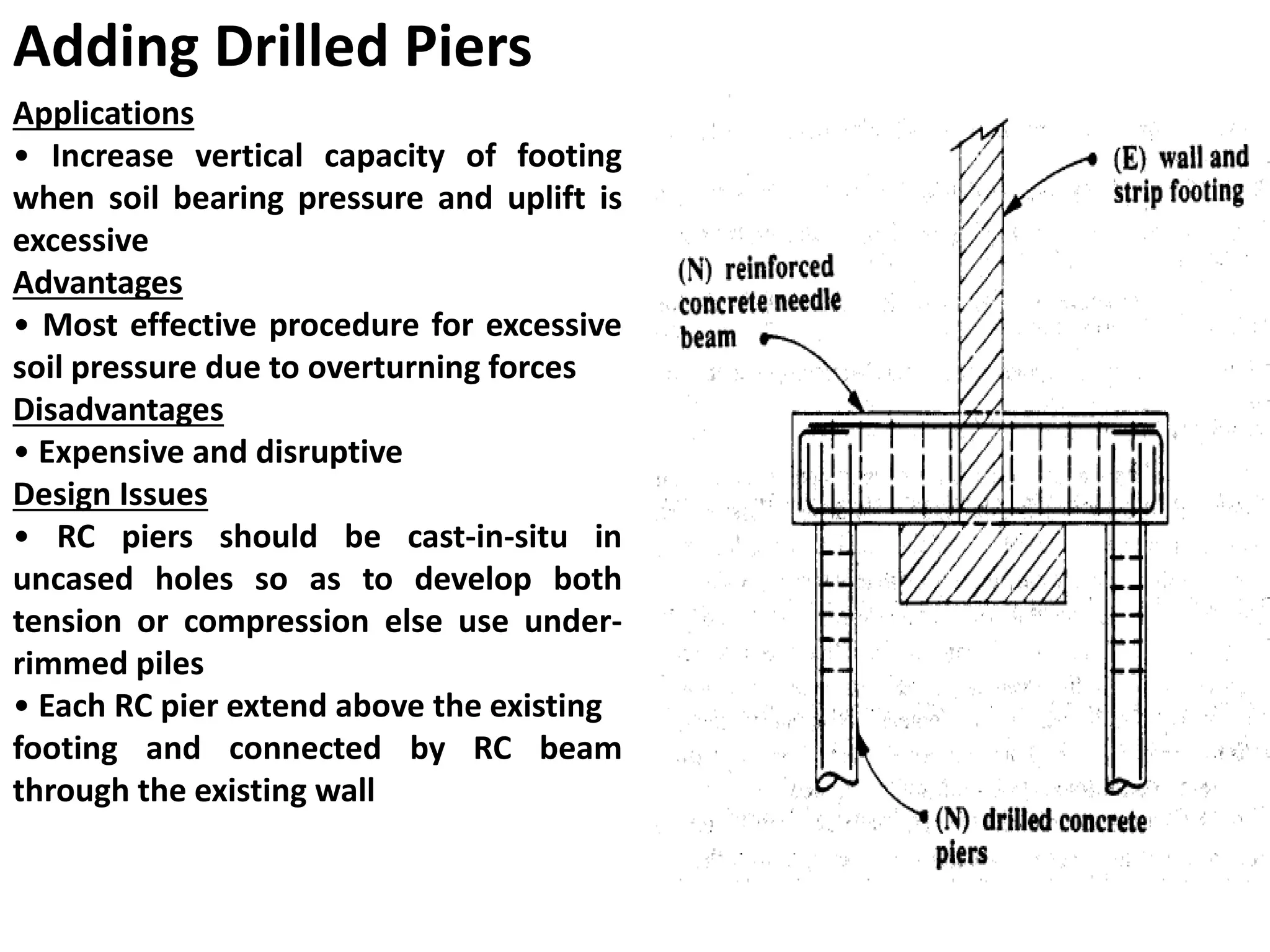

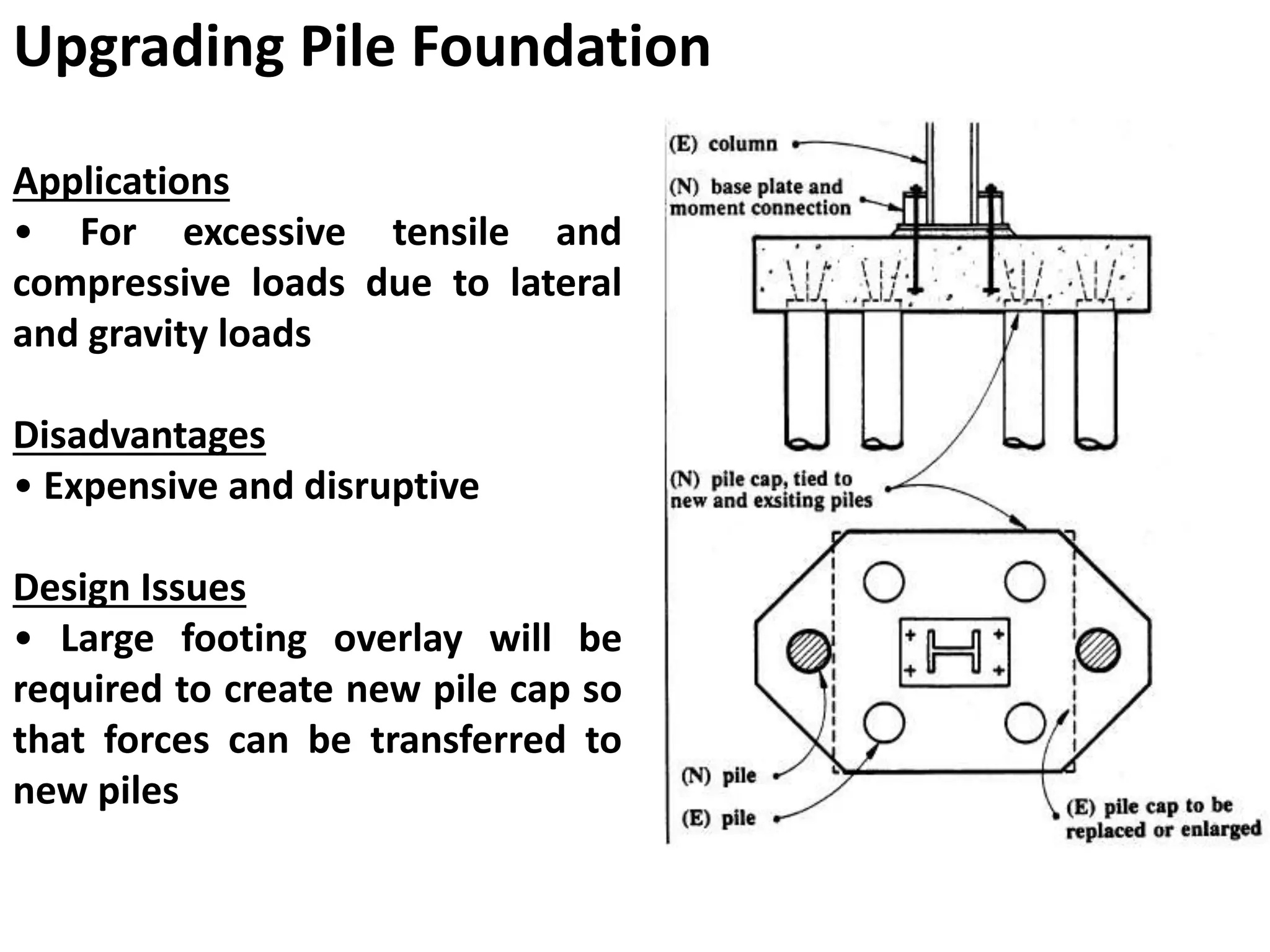

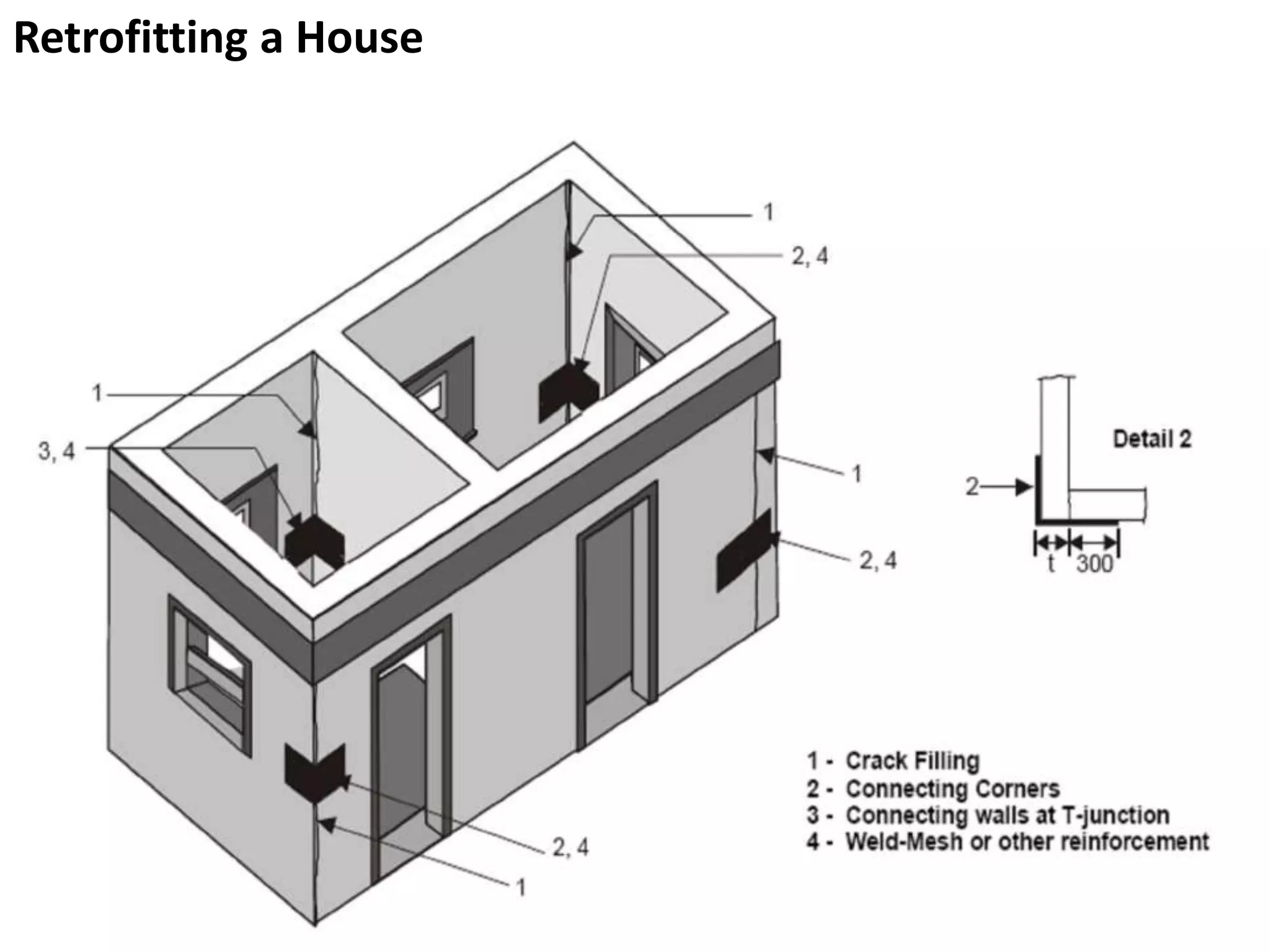

Structural retrofitting involves strengthening existing structures to withstand earthquake loads. Retrofitting techniques discussed include adding shear walls, concrete or steel jacketing of columns, steel plating or fiber wrapping of beams, and upgrading foundations. The objectives of retrofitting are to increase strength and ductility, provide unity to the structure, eliminate weaknesses, avoid brittle failures, and enhance redundancy. Effective retrofitting ensures the intended performance is reliably achieved in a cost-effective manner.