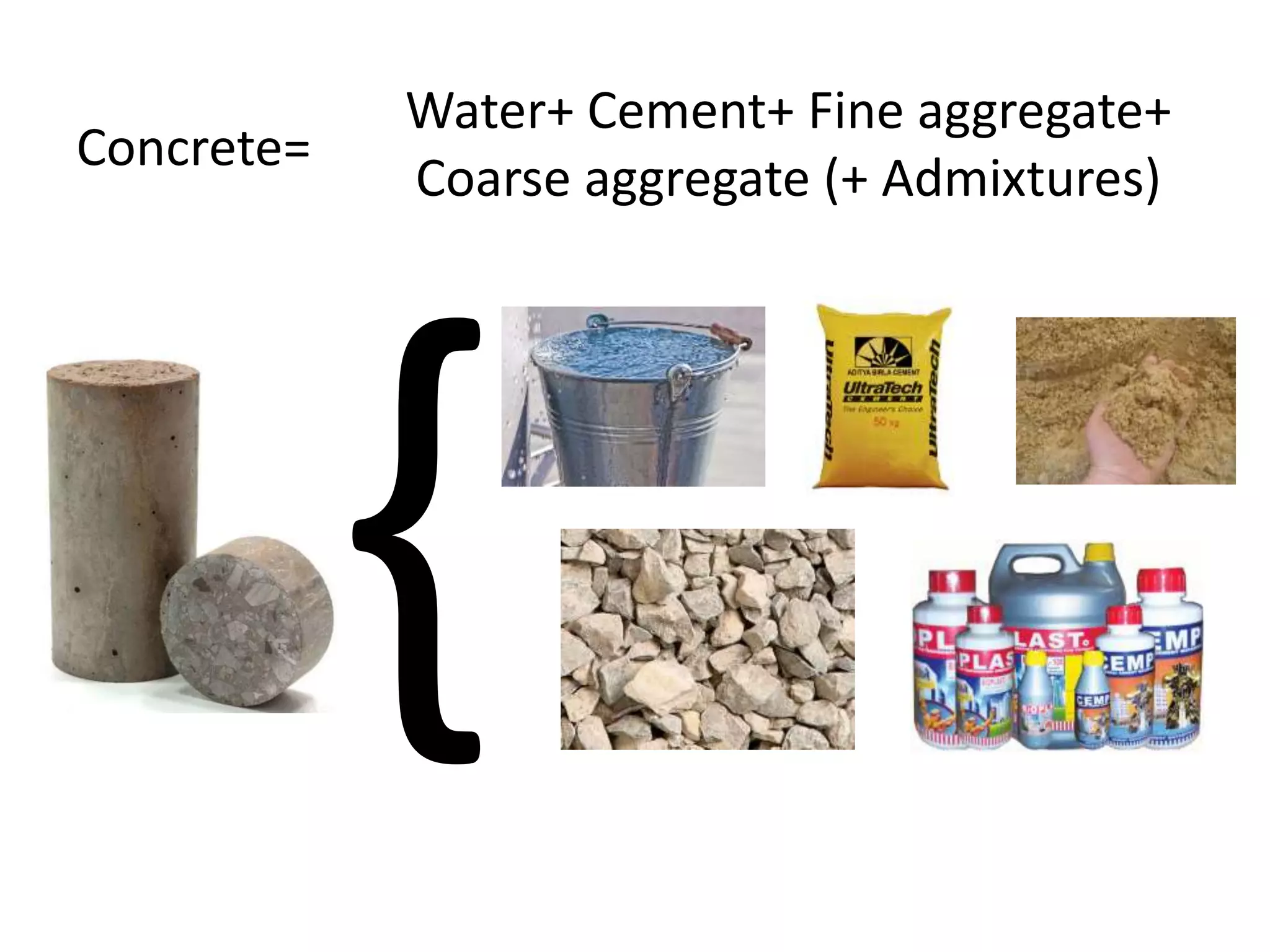

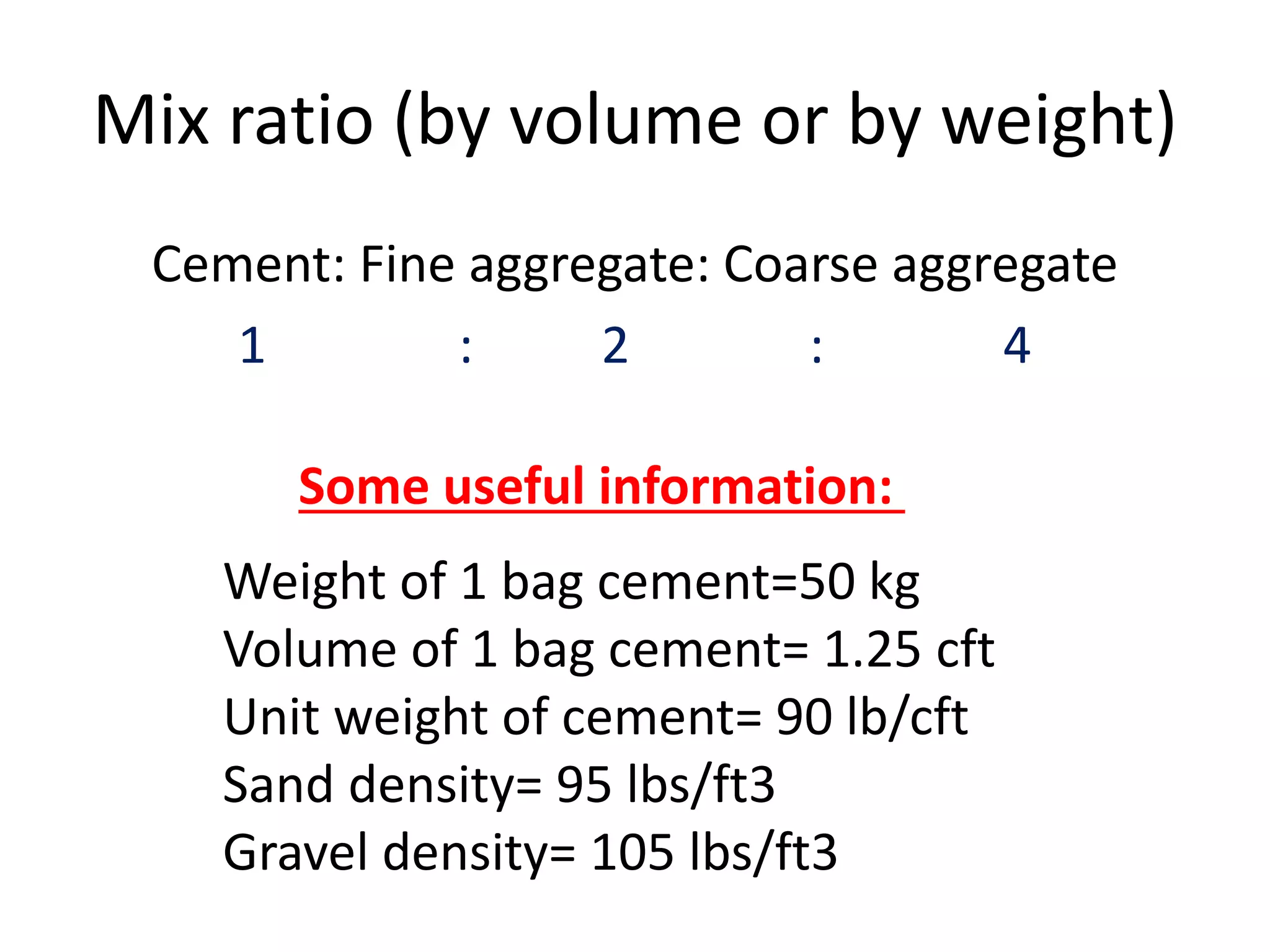

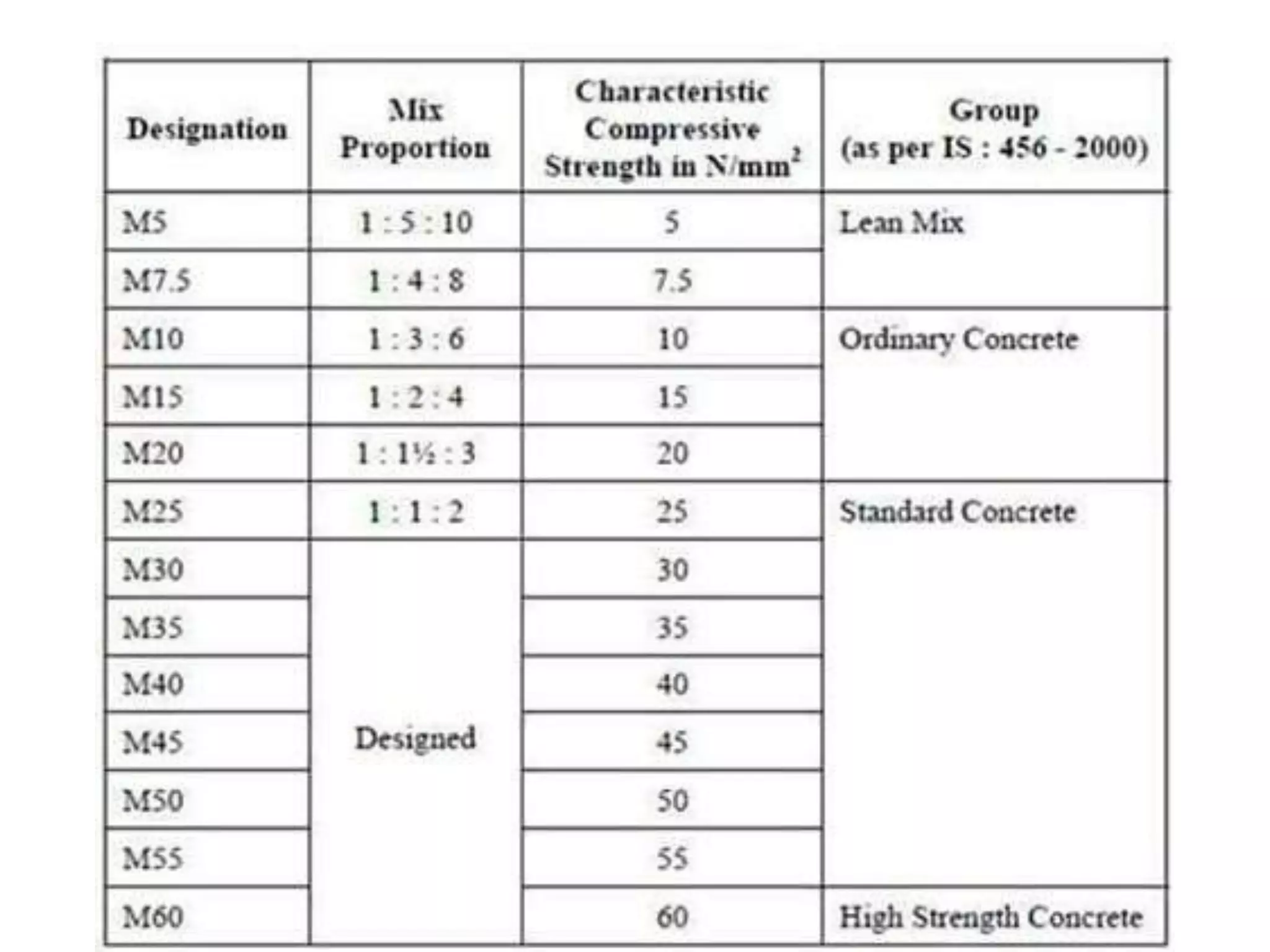

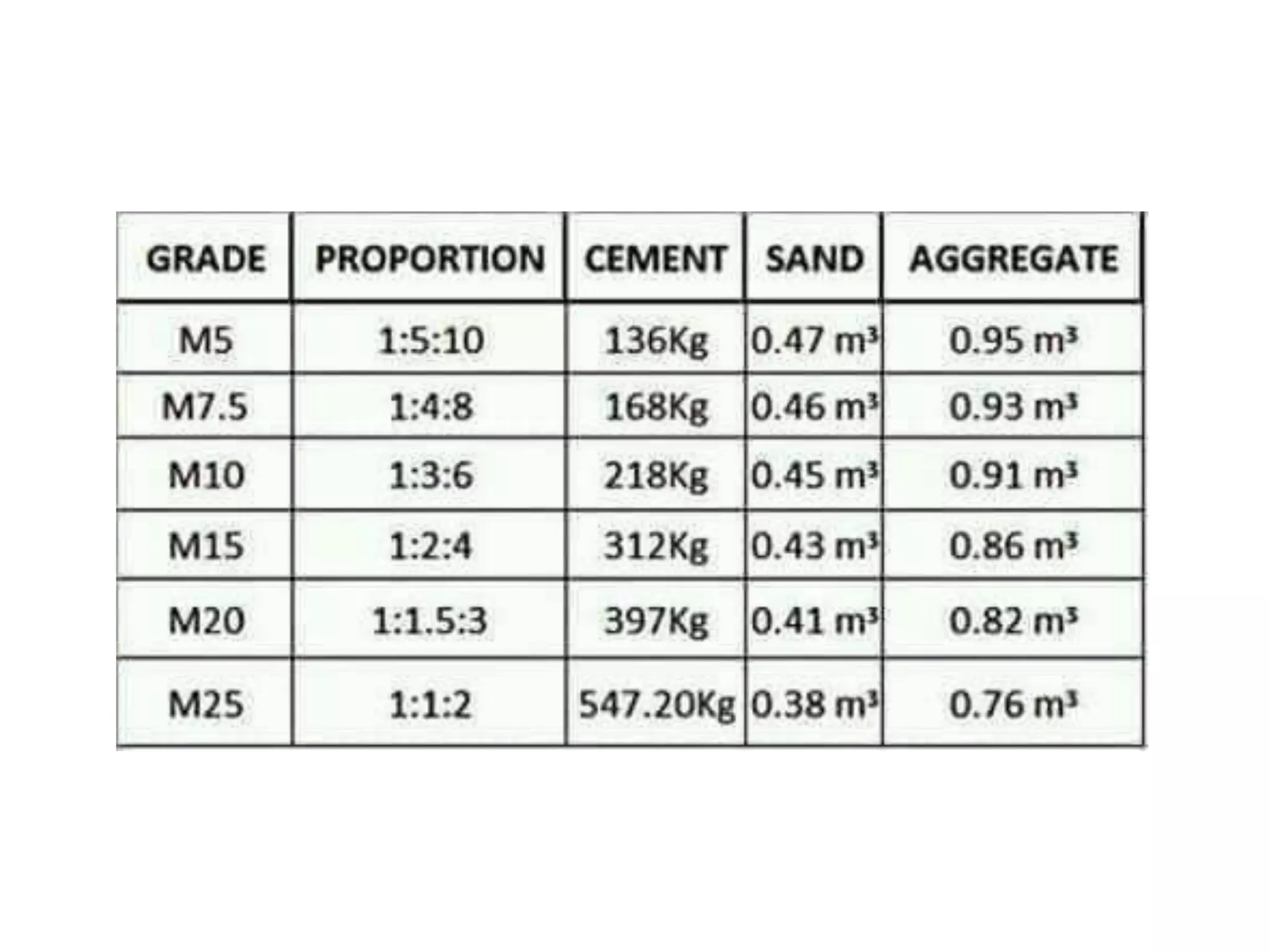

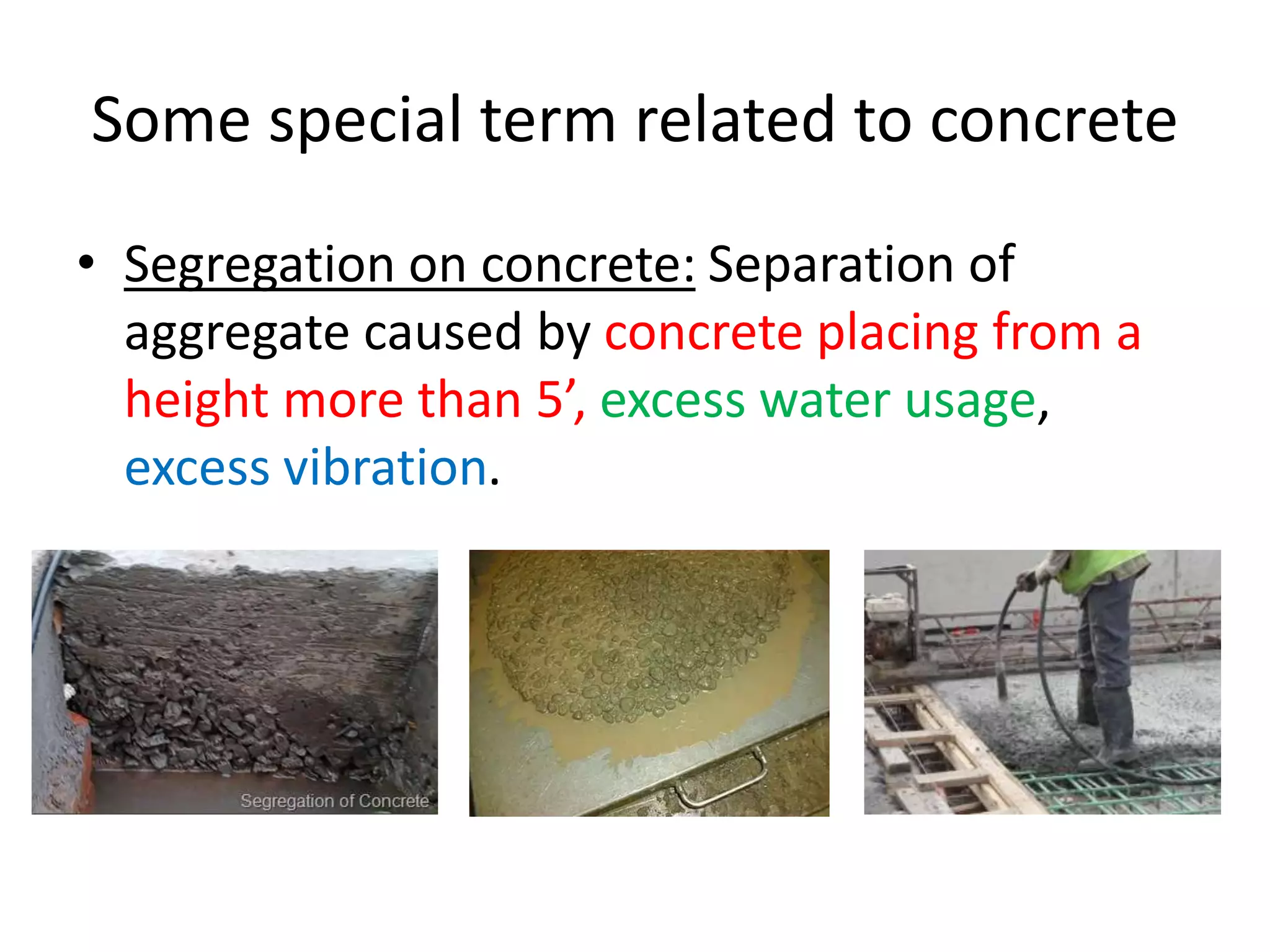

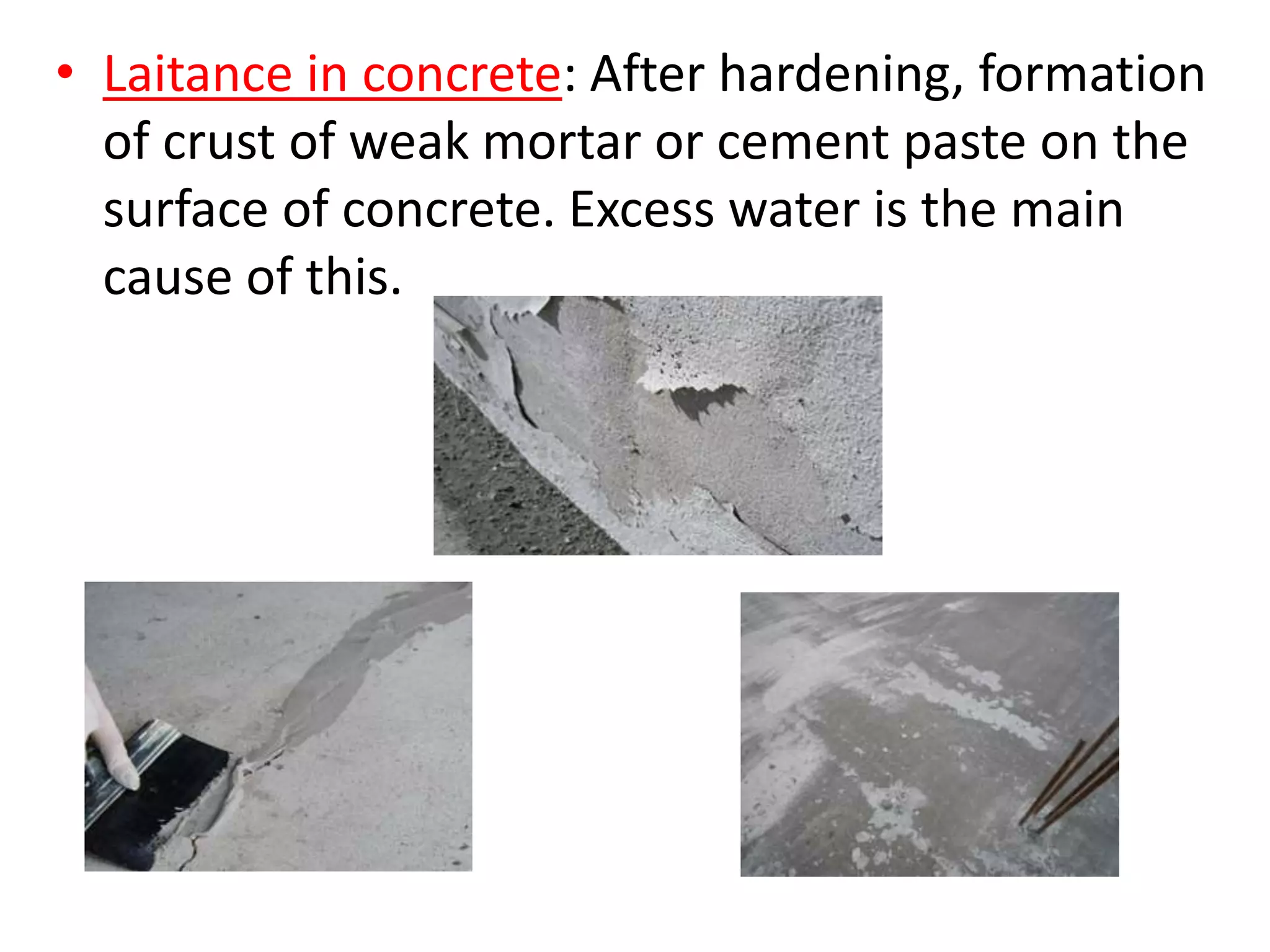

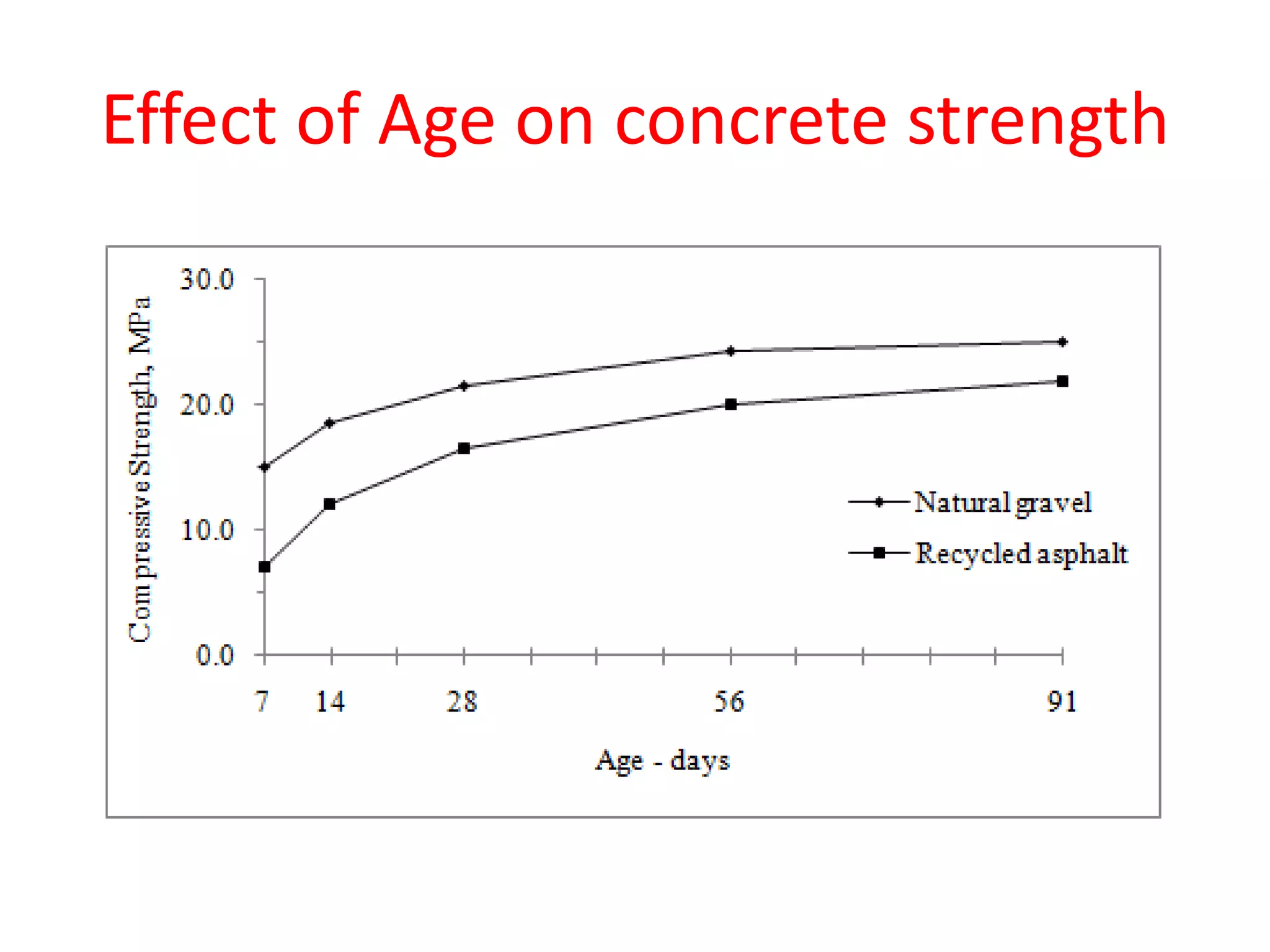

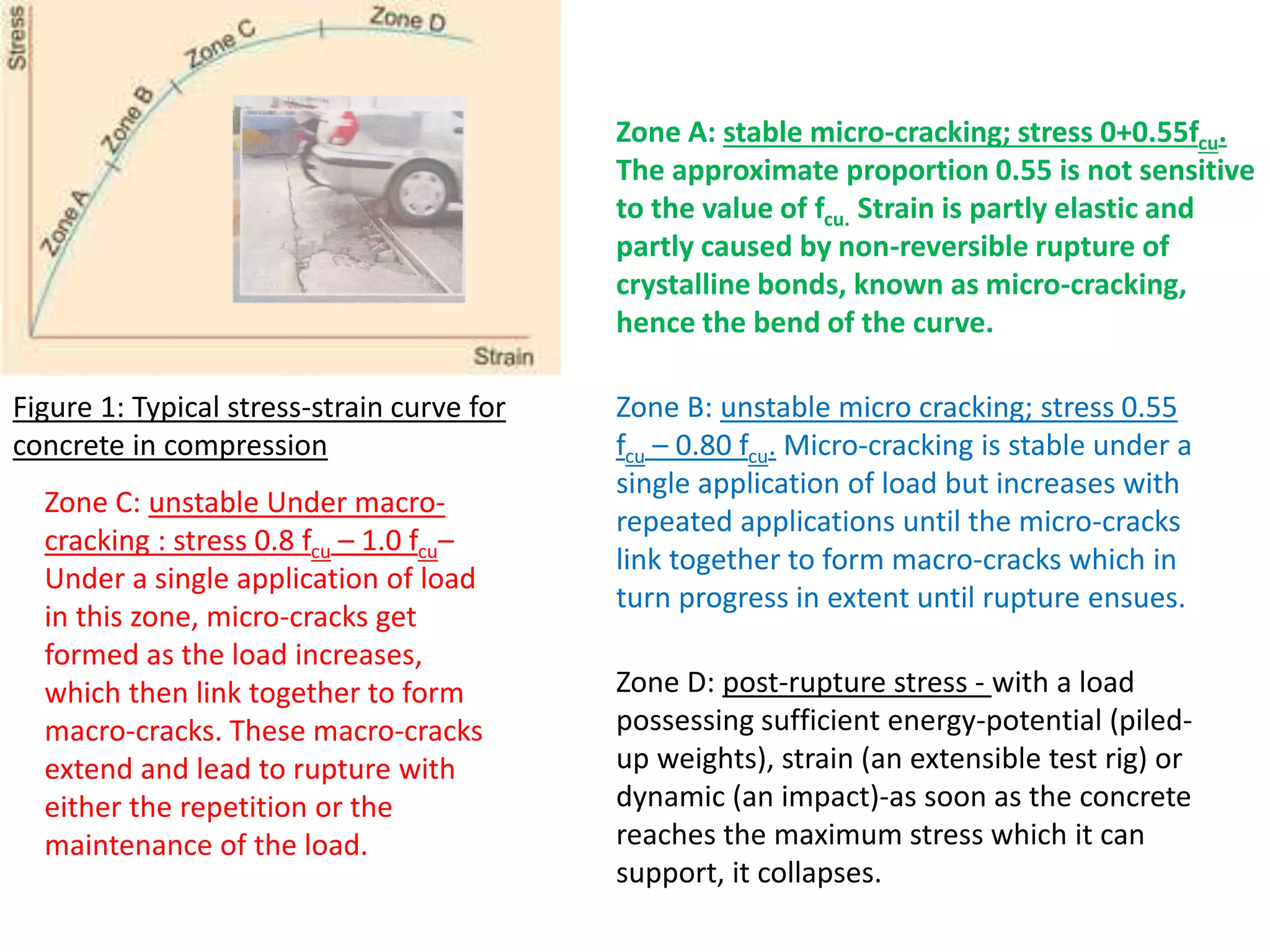

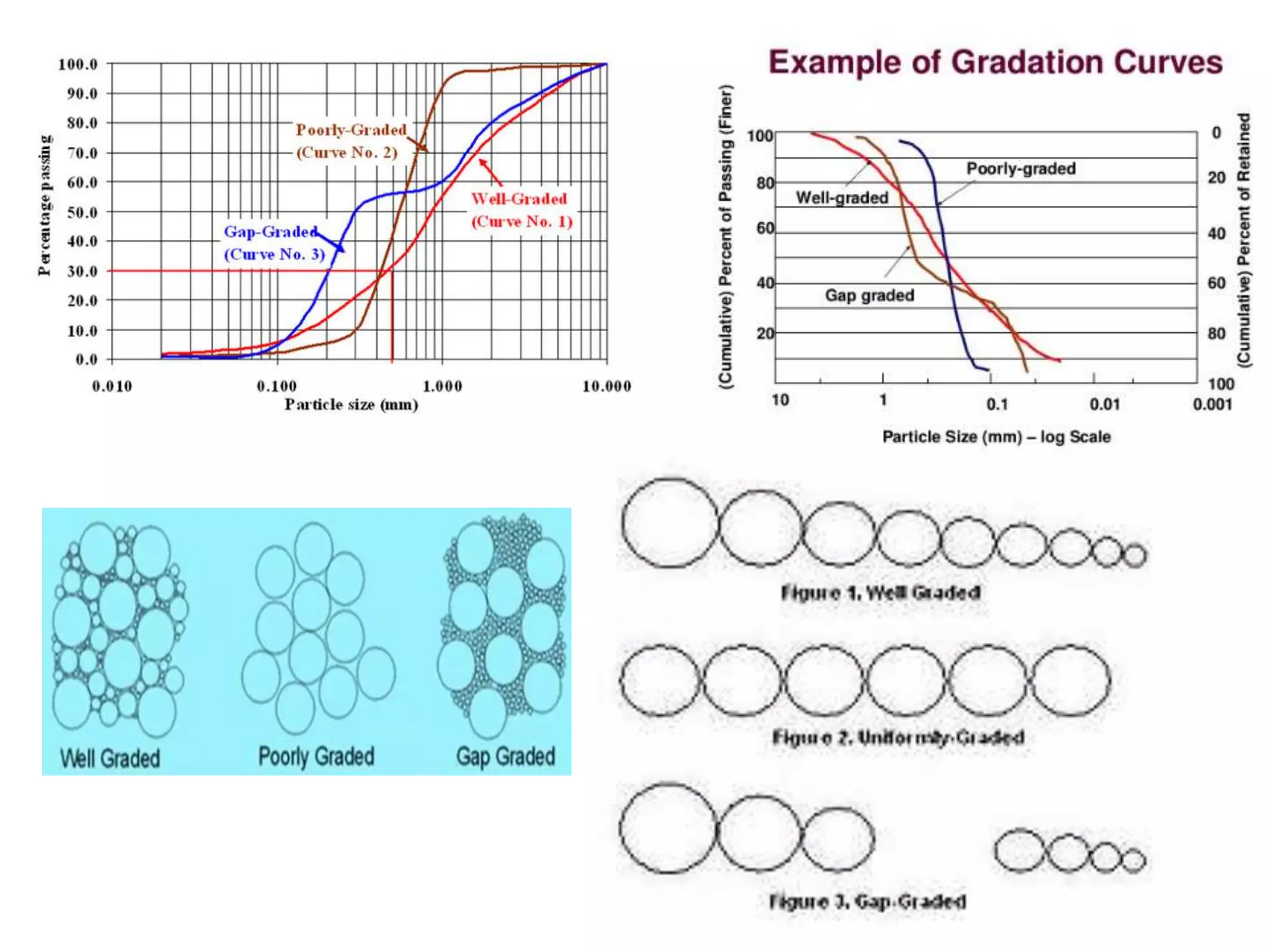

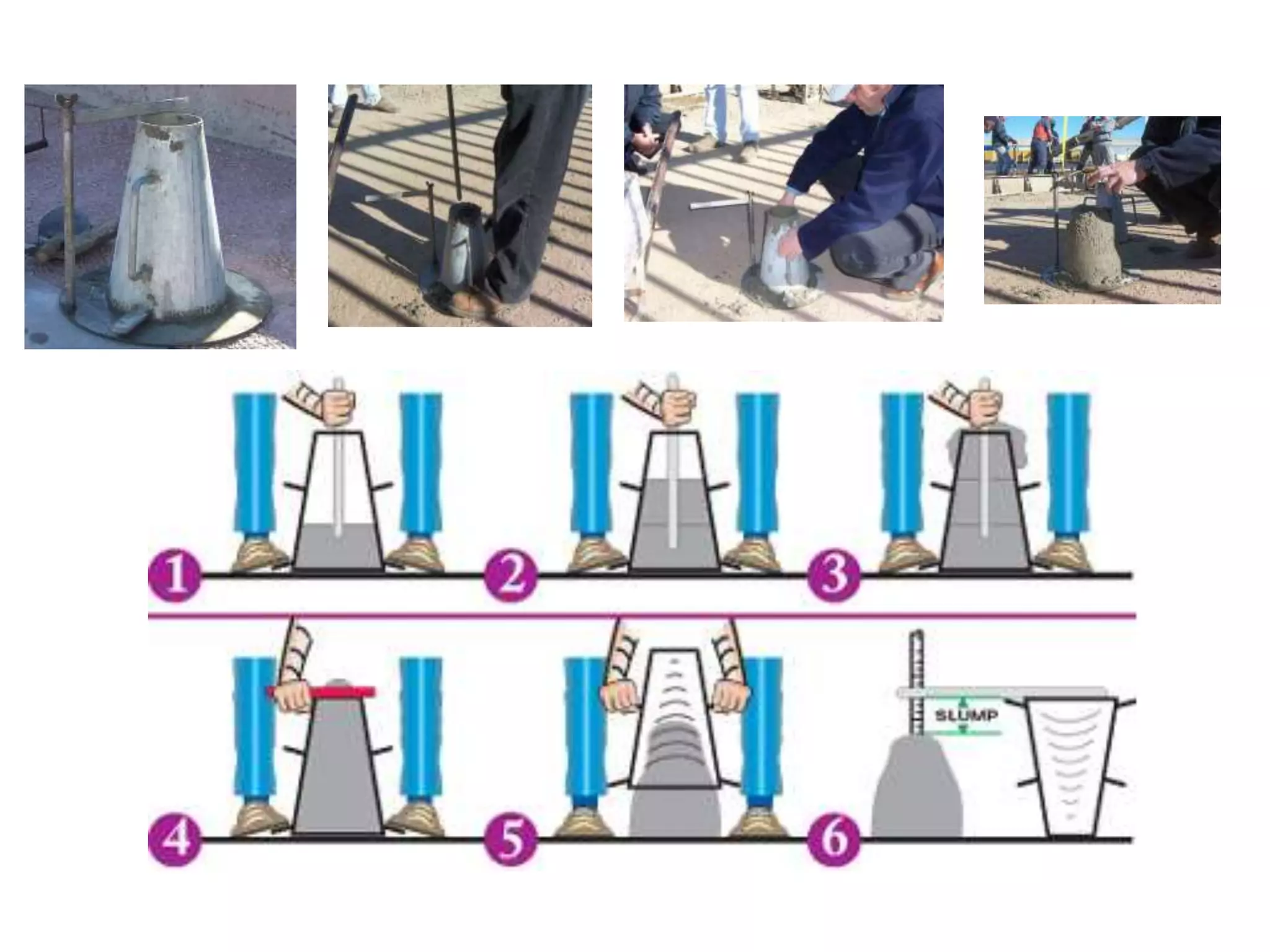

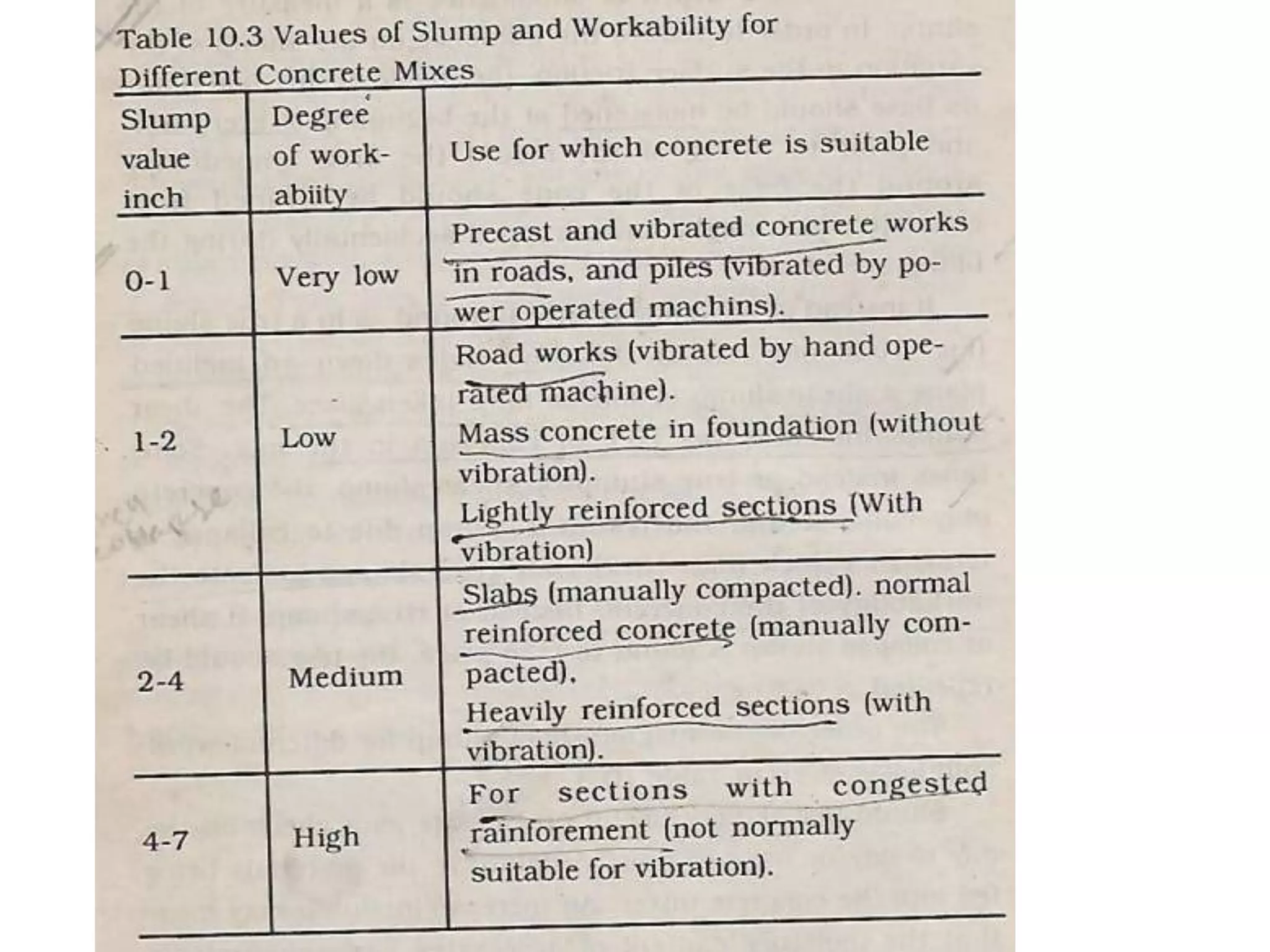

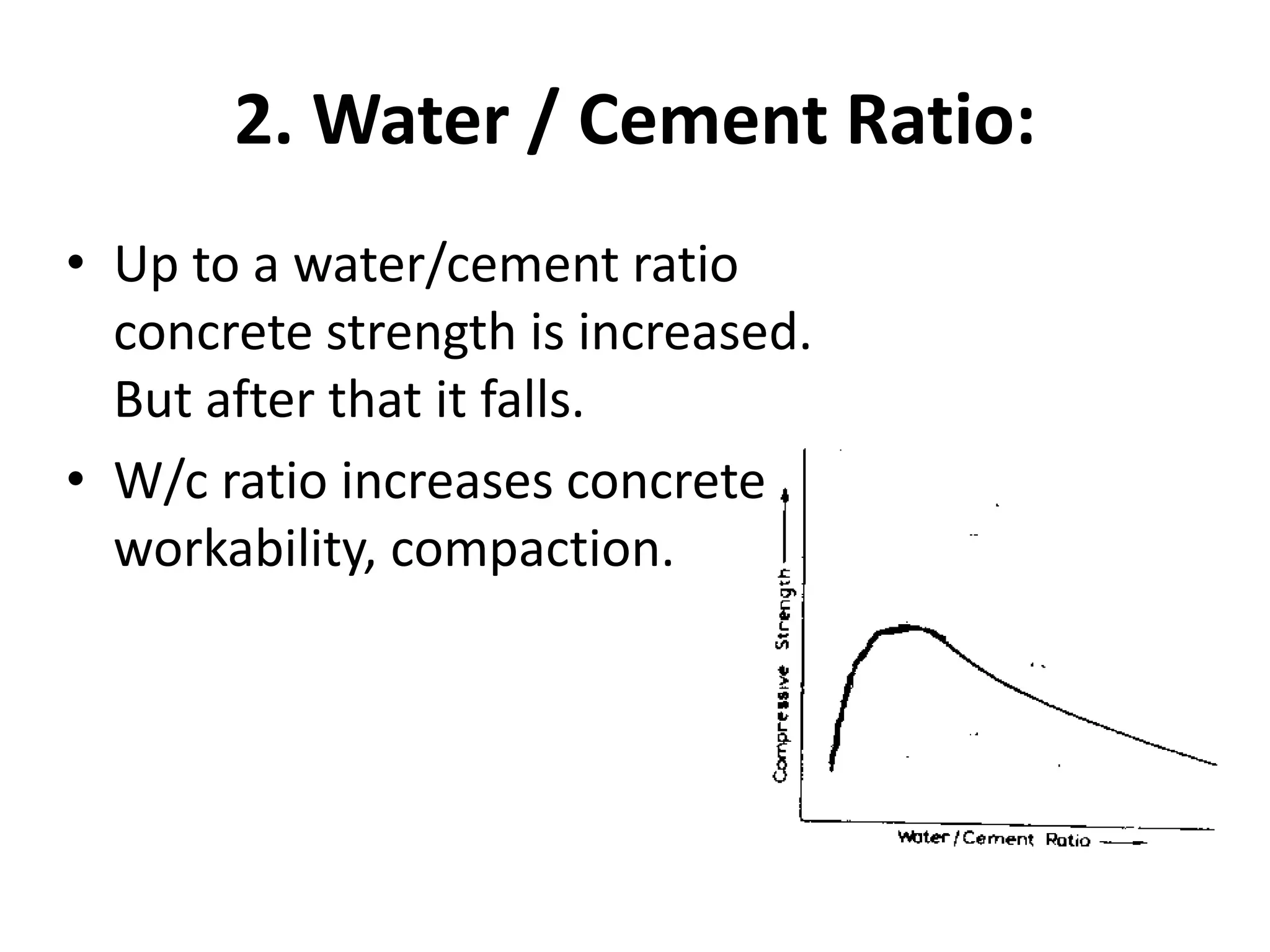

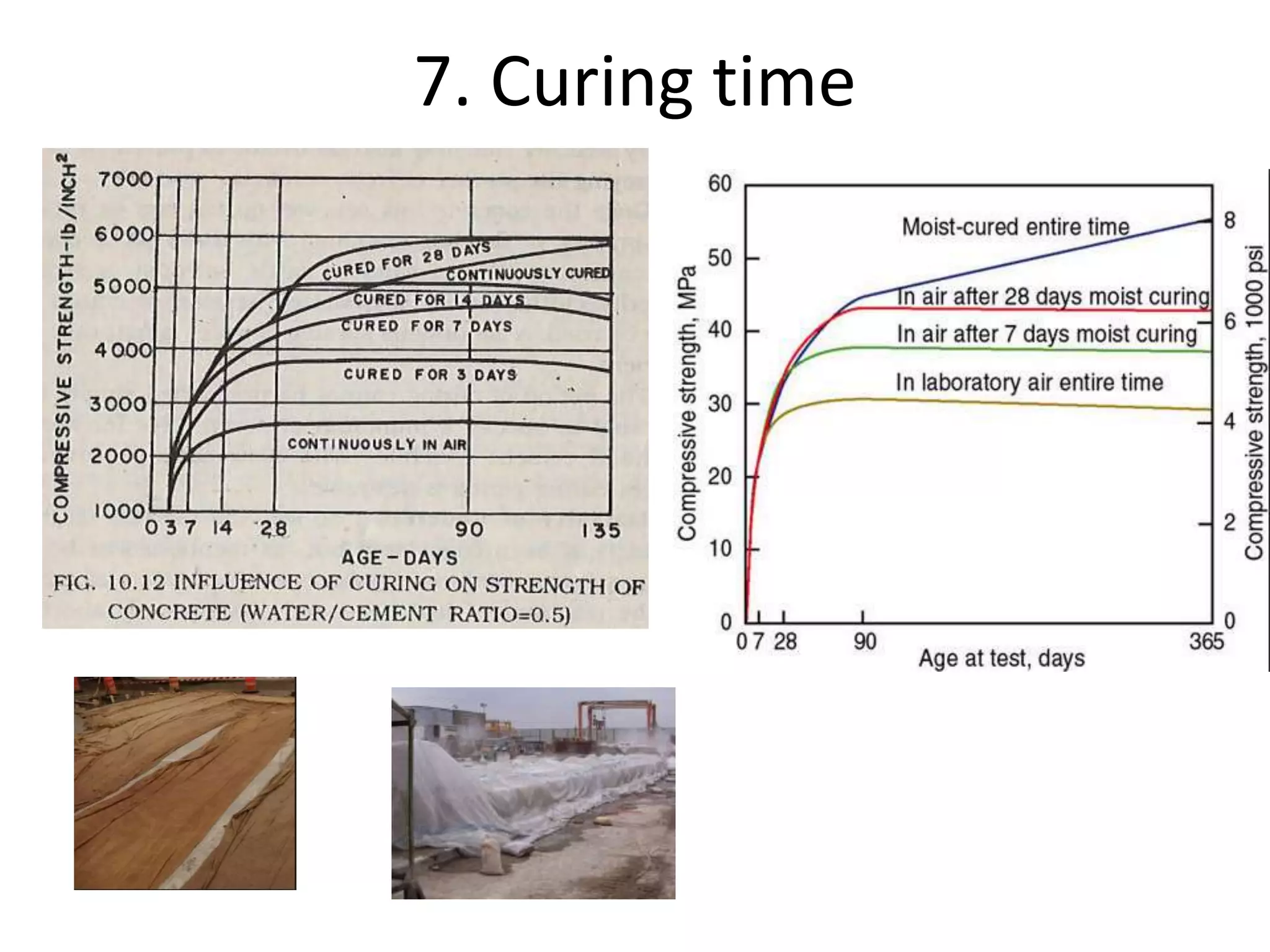

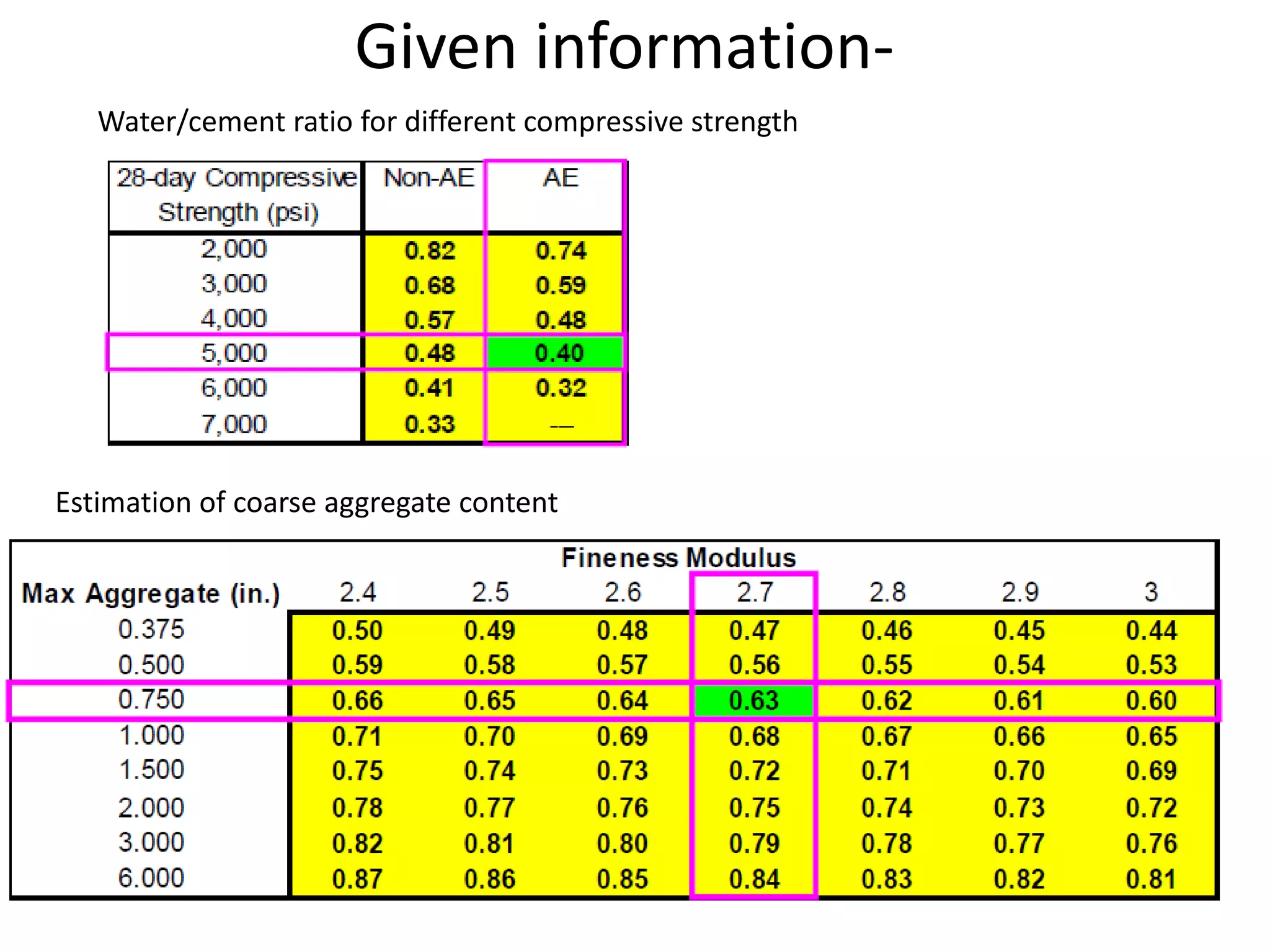

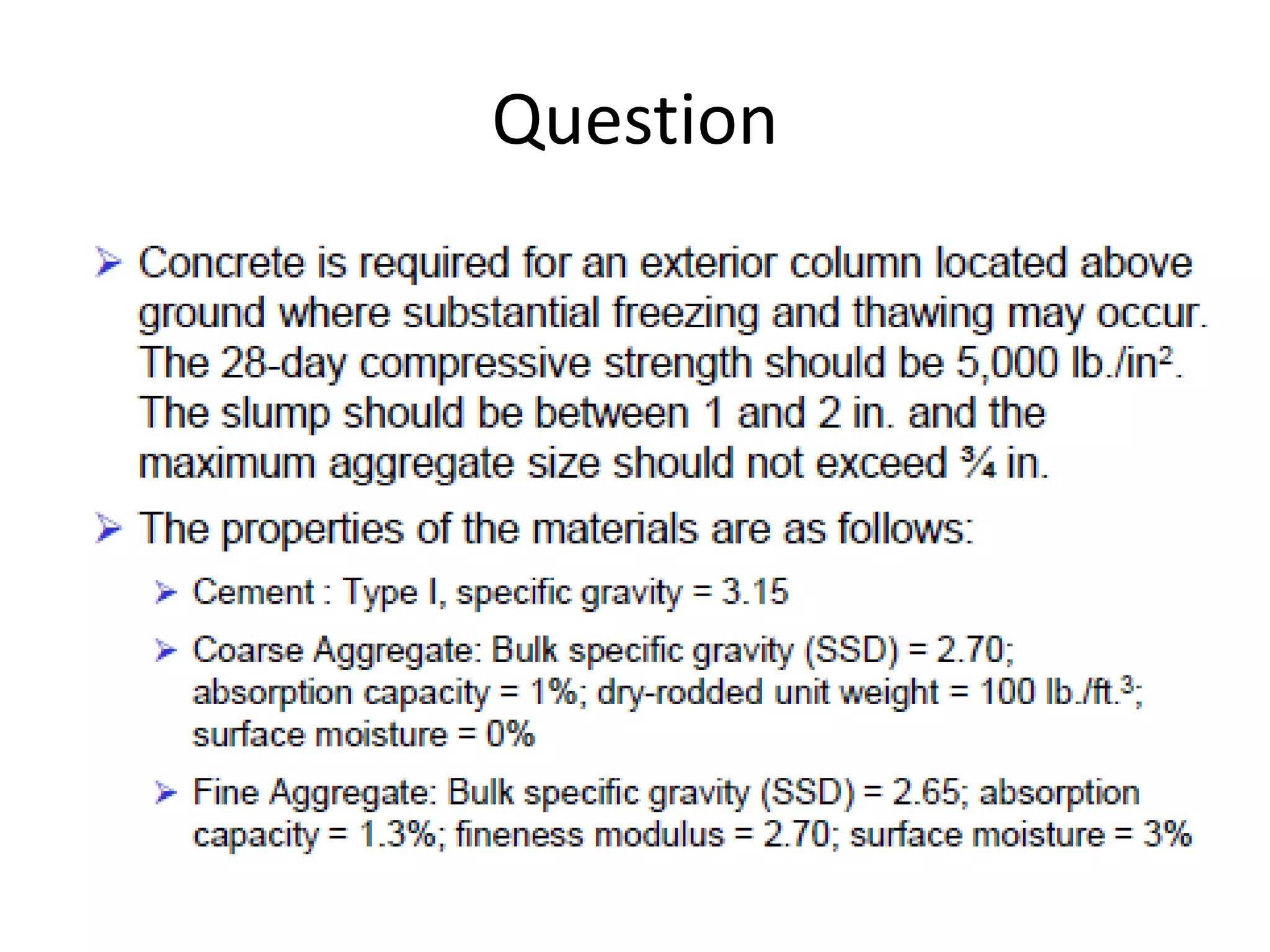

The document provides an overview of concrete, including its composition, properties, and factors that affect its performance. Concrete is made by mixing water, cement, fine aggregate (sand), and coarse aggregate (gravel) in specific proportions. Its key properties include strength in compression but weakness in tension. Strength increases with curing time. Workability, permeability, durability, and elasticity are also addressed. Factors like water-cement ratio, compaction, aggregate size and quality influence concrete properties.