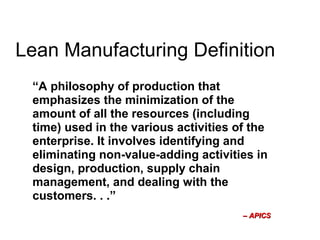

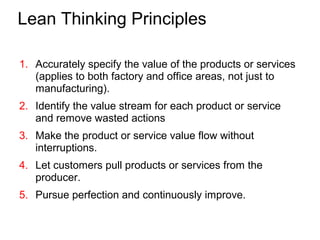

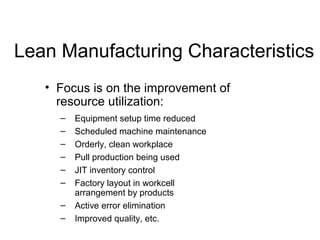

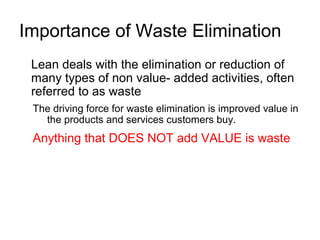

The document outlines lean manufacturing, originating from Taiichi Ohno's Toyota production system, emphasizing waste elimination and resource optimization in production processes. It details principles and steps for implementing a lean manufacturing system aimed at delivering maximum value to customers with minimal waste. Key benefits include reduced costs, improved quality, and enhanced customer satisfaction.