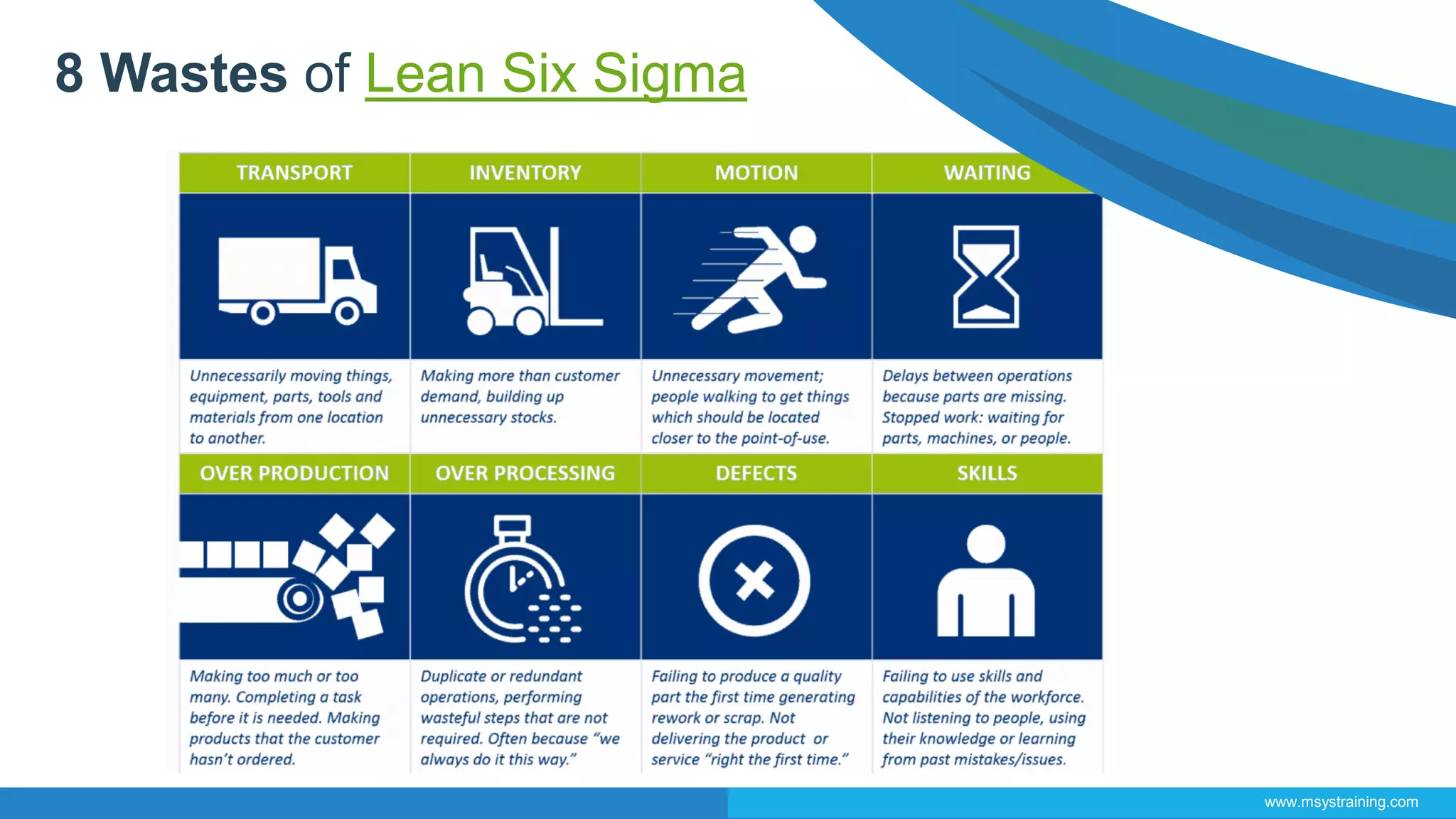

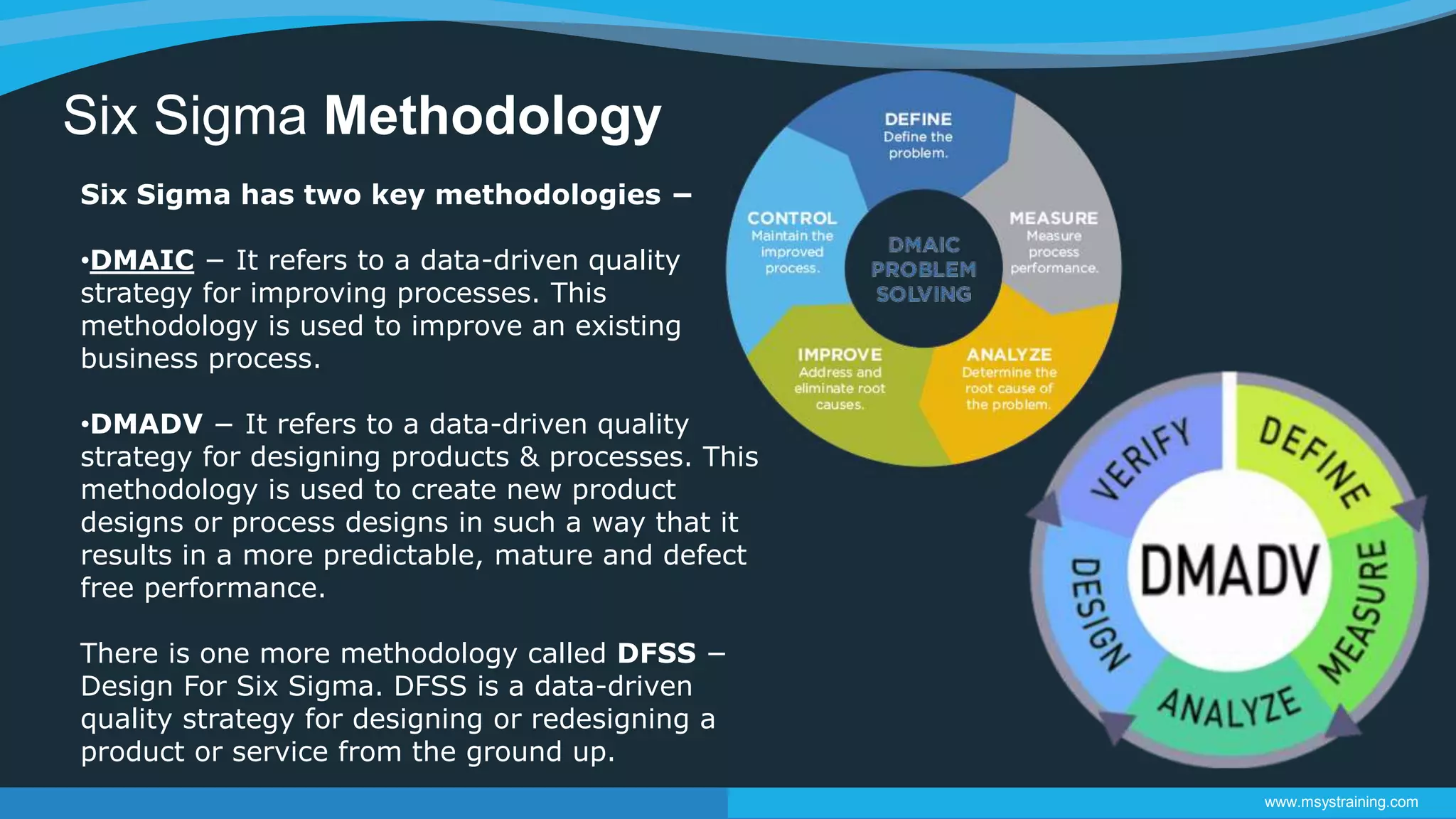

The document outlines the concept of 'waste' in lean thinking, emphasizing the importance of eliminating non-value-adding activities to enhance customer satisfaction. Originally detailed by Taiichi Ohno, the seven types of waste are talent, inventory, motion, waiting, overproduction, overprocessing, and defects, later expanded to include non-utilized talent as the eighth waste. It also introduces Six Sigma methodologies, DMAIC for improving existing processes, DMADV for designing new processes, and DFSS for building products from scratch.