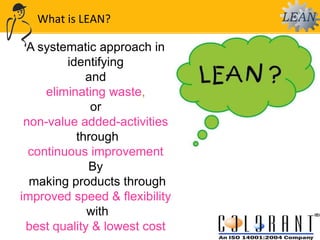

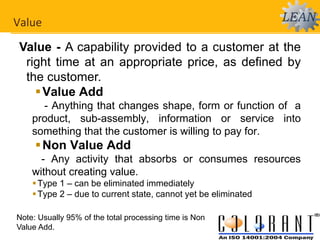

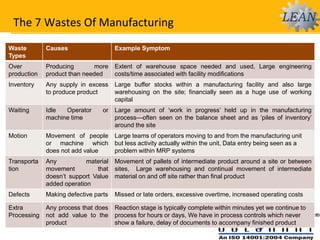

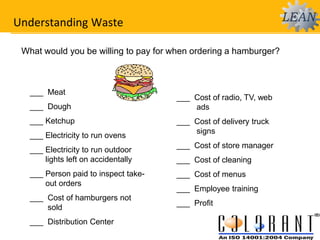

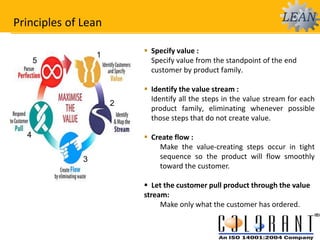

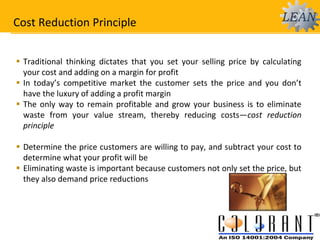

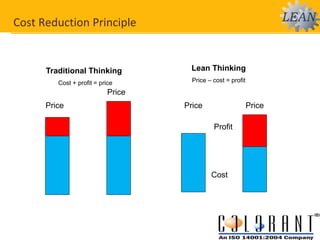

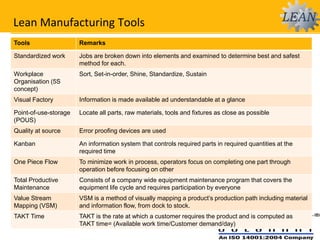

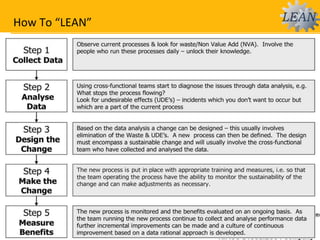

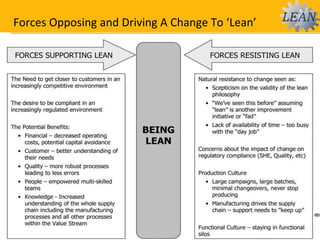

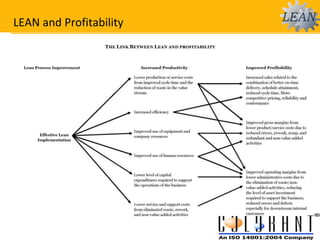

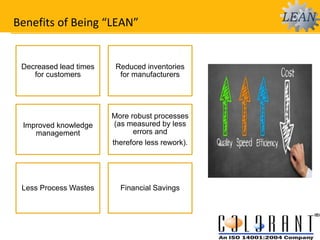

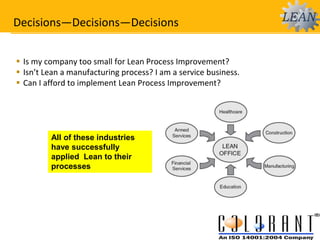

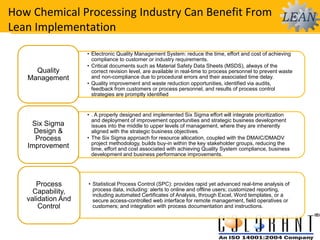

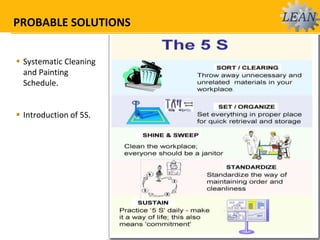

The document presents lean management concepts applied to the textile industry, emphasizing the identification and elimination of waste to improve efficiency and reduce costs. It details various types of waste, lean principles, and tools, as well as how lean practices can benefit both manufacturing and service-oriented businesses. The conclusion highlights that lean is a comprehensive approach impacting all organizational levels, aimed at delivering value by minimizing waste.