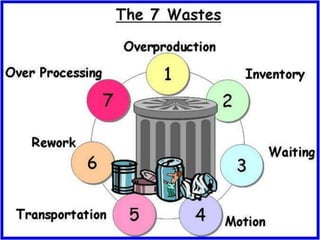

1) The Toyota Production System (TPS) was developed by Taiichi Ohno and others at Toyota to eliminate waste in production.

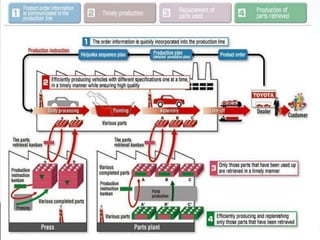

2) TPS is based on two key concepts: Jidoka, which stops production when quality issues are detected, and Just-in-Time, which produces only what is needed when it is needed.

3) Other aspects of TPS include reducing set-up times, small lot production, employee involvement, quality control, and supplier involvement.