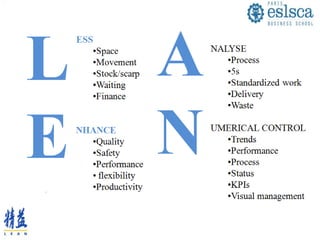

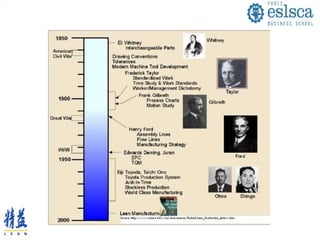

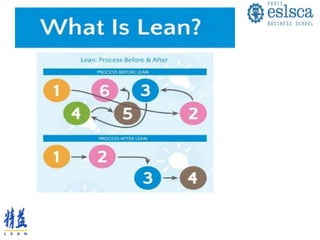

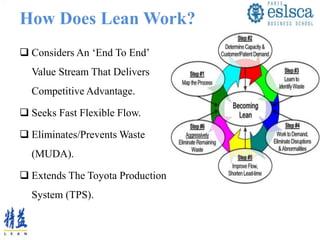

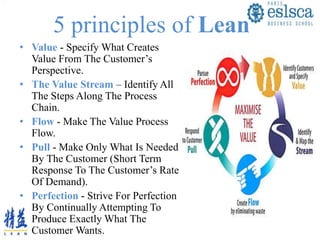

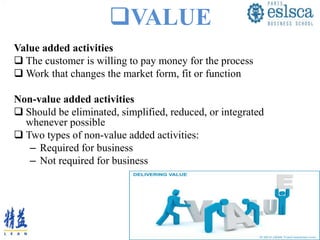

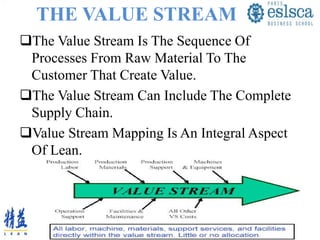

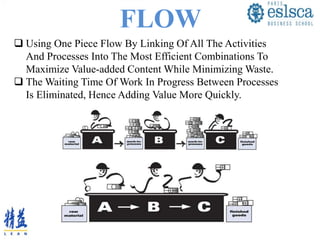

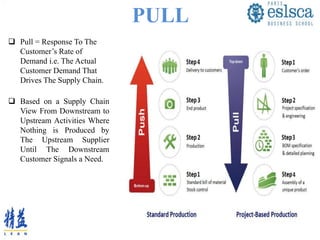

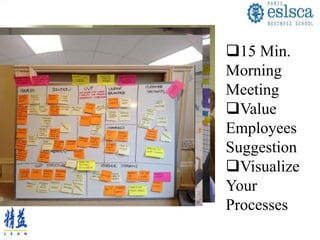

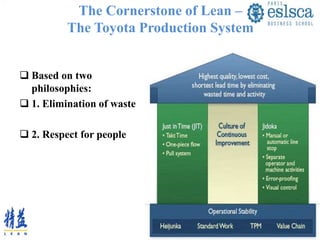

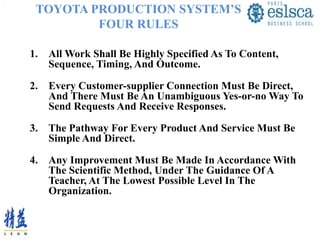

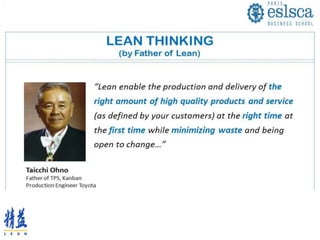

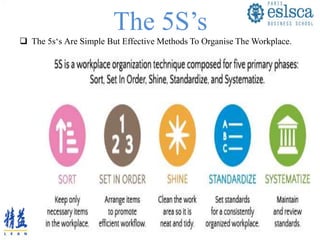

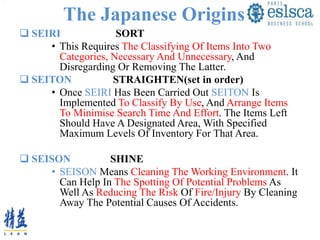

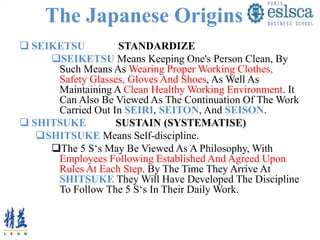

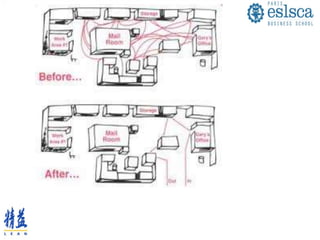

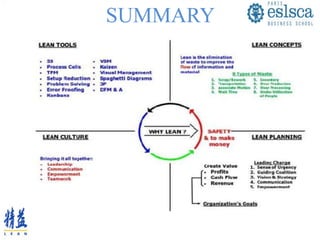

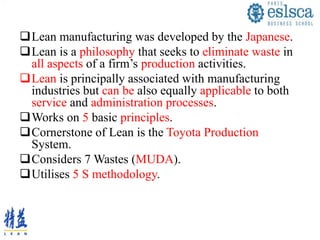

The document discusses the concepts of lean thinking and lean manufacturing. It covers the origins of lean in the Japanese automotive industry, the five main principles of lean, the Toyota Production System, the seven wastes, and the 5S methodology. The key aspects are summarized in three sentences.