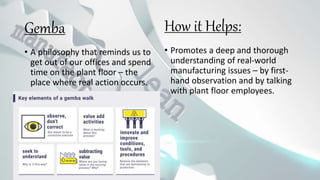

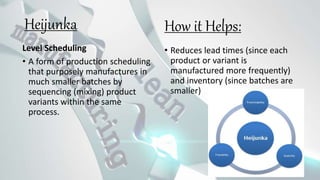

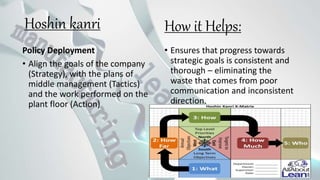

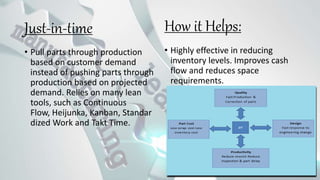

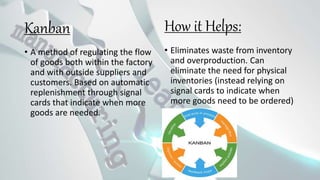

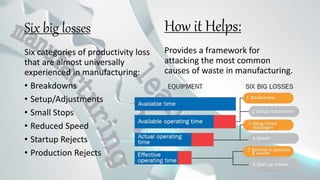

This document describes 25 lean tools used to eliminate waste and improve manufacturing processes. It provides a brief description of each tool, including how it helps reduce waste. Some of the key tools discussed are 5S, which organizes and standardizes the workplace; ANDON, a visual system that alerts others when help is needed; bottleneck analysis for improving throughput; and value stream mapping to identify opportunities for process improvement. The overall goal of these various lean tools is to maximize value and minimize waste in production.