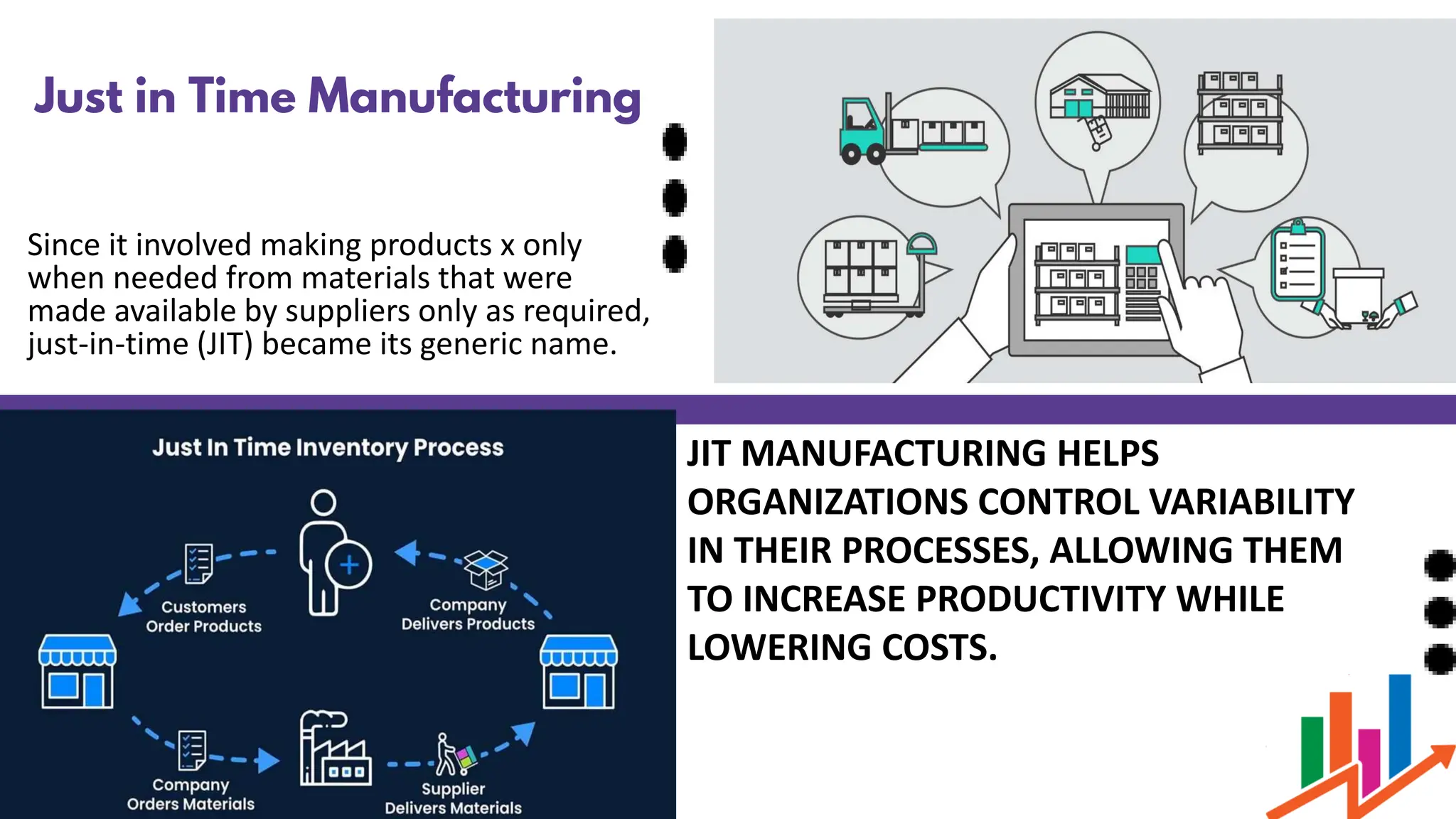

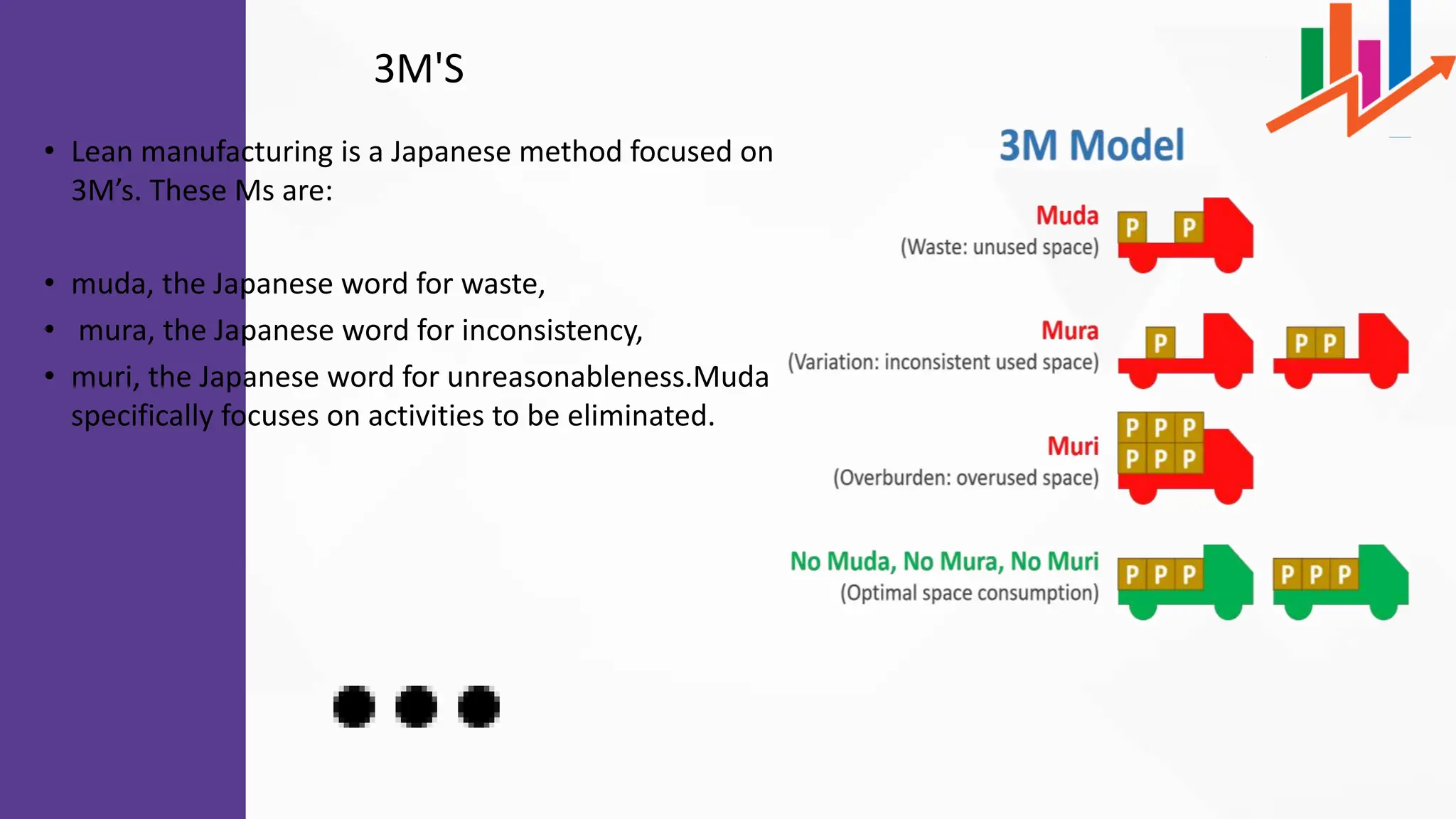

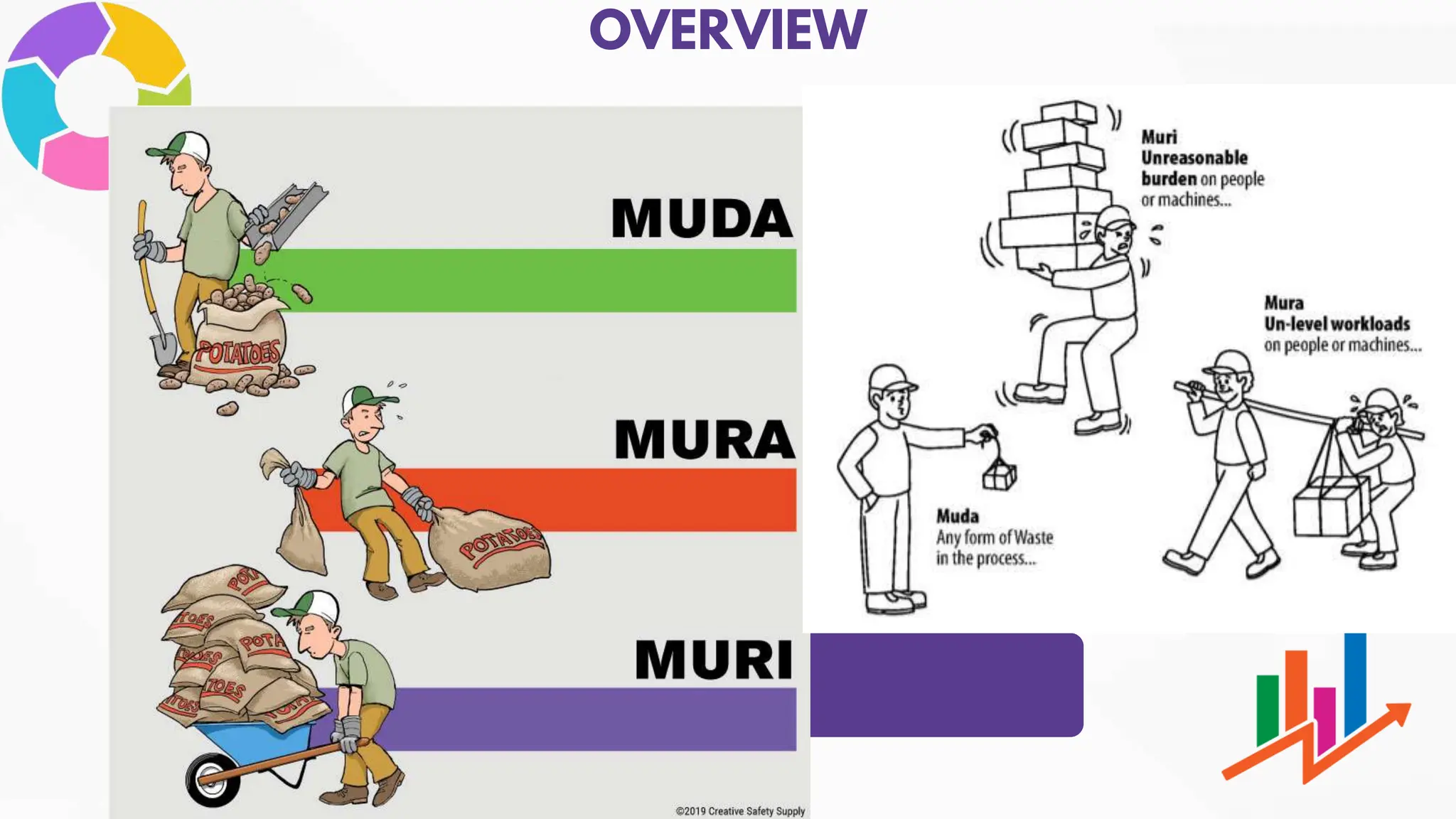

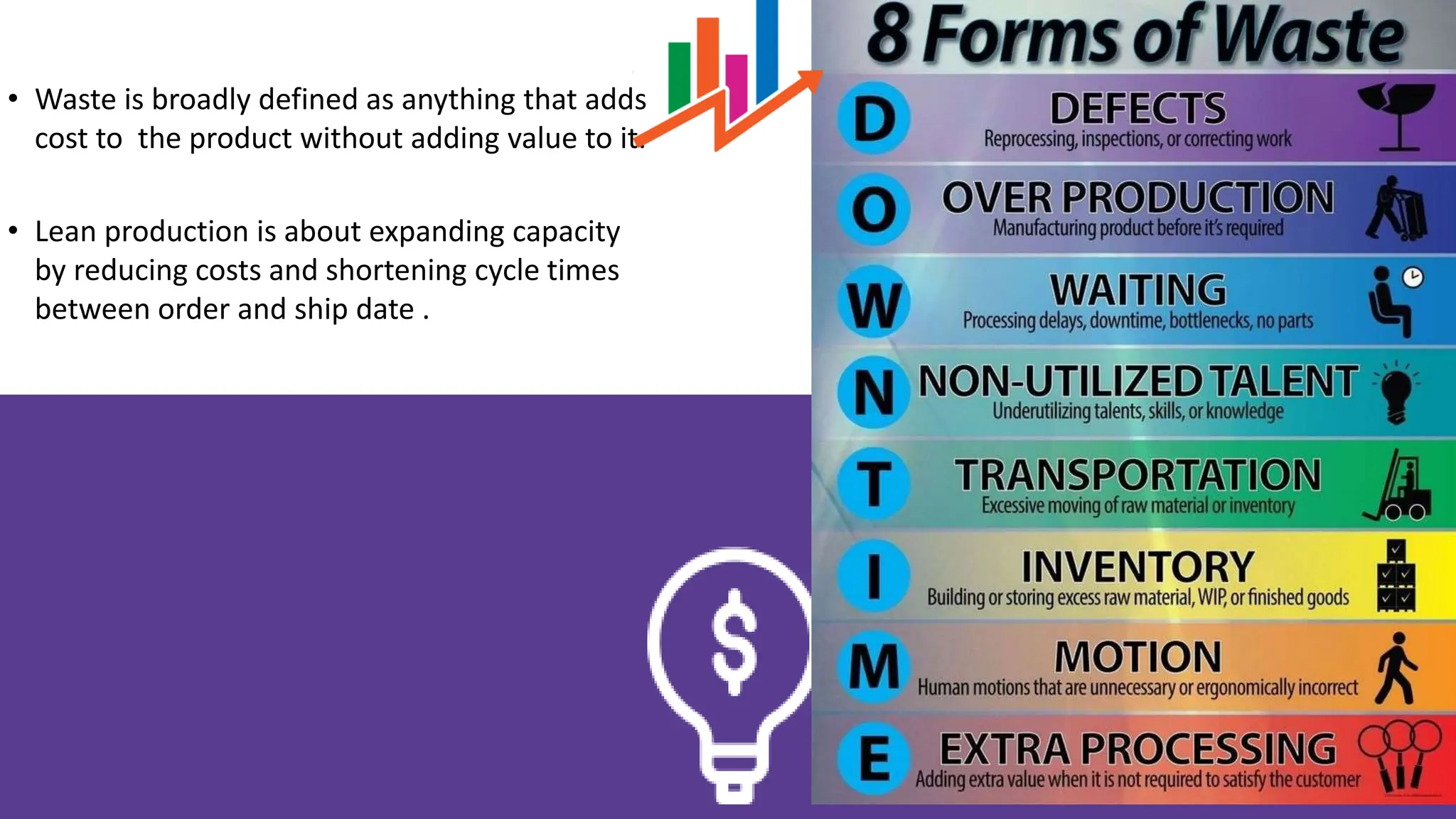

Lean manufacturing is a systematic approach focused on eliminating waste, enhancing productivity, and reducing costs, originally developed by Taiichi Ohno in the 1950s. It employs principles such as Just-In-Time (JIT) production, the 3M's of waste (muda, mura, muri), and continuous improvement (kaizen) to streamline processes. The benefits include cost reduction, improved quality, increased customer satisfaction, and enhanced employee morale.

![Genesis of Lean

Manufacturing

Lean Manufacturing

• “Perfection is not attainable. But if

we chase perfection, we can catch

excellence.” Vince Lombardi

• Lean manufacturing or lean

production are reasonably new terms that

can be traced to Jim Womack, Daniel Jones

and Daniel Roos’ book, The Machine that

changed the world [1991]](https://image.slidesharecdn.com/aleanmanufacturingmc-240319143646-8c00a606/75/Lean-Manufacturing-5S-3M-Advantages-of-Lean-Manufacturingng-3-2048.jpg)