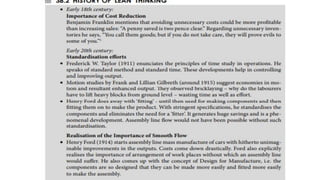

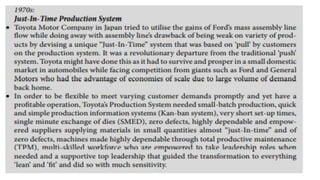

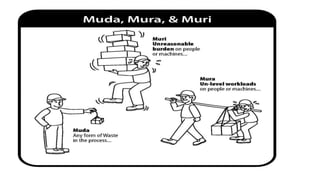

Lean manufacturing aims to maximize productivity while minimizing waste. It focuses on eliminating "muda," or waste, through efficient processes that integrate each production step holistically. The "5S" technique is used to eliminate waste through sorting, systematic organization, sweeping, standardizing, and sustaining clean and organized workplaces. Key aspects of lean include just-in-time production to avoid overproduction and excess inventory, continuous improvement through kaizen, and leadership commitment to instill a culture of waste elimination.