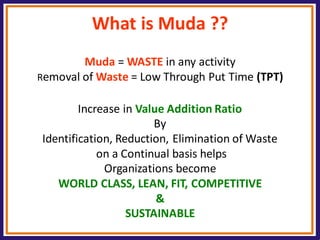

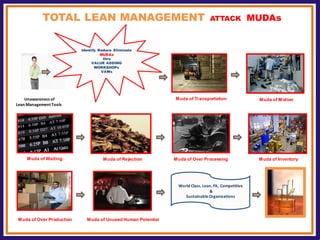

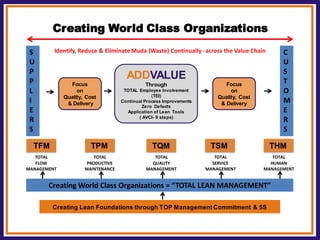

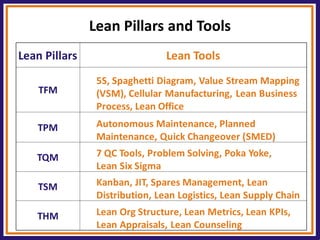

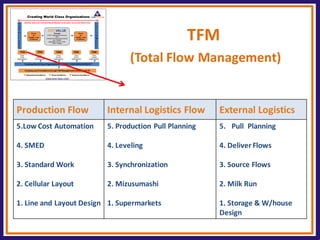

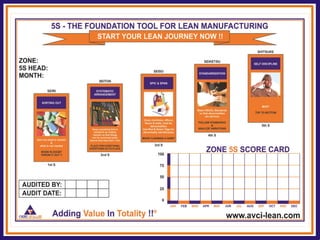

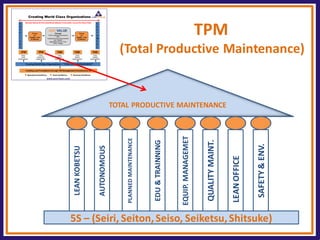

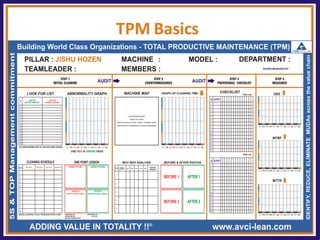

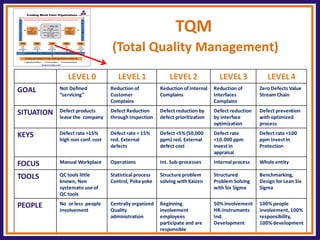

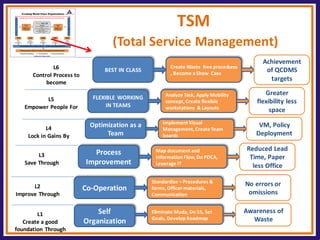

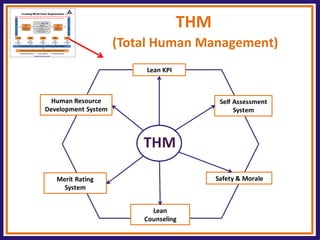

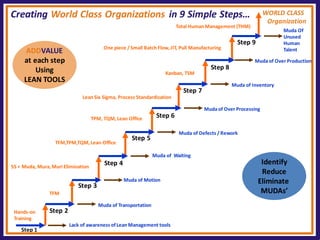

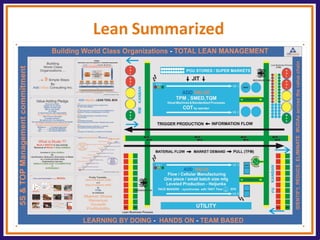

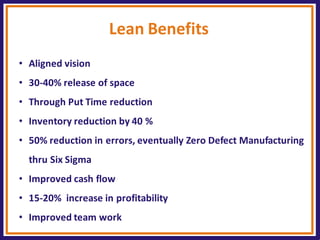

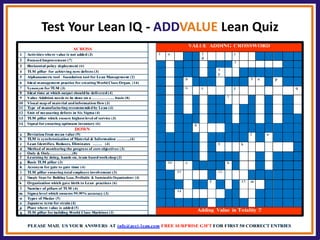

The document outlines a comprehensive approach to creating world-class organizations through lean management principles, emphasizing the identification and elimination of waste (muda) across various processes. It details various lean tools and methodologies, including Total Flow Management (TFM), Total Productive Maintenance (TPM), and Total Quality Management (TQM), aimed at enhancing operational efficiency and employee involvement. The goal is to foster a culture of continuous improvement, resulting in reduced costs, improved quality, and increased profitability.