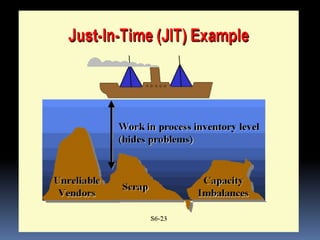

The document provides an overview of a presentation by "The Super Seven" on Just in Time. It includes sections on introduction, history, definition, objectives, characteristics, benefits, limitations, methodology and elements. The presentation covers how Just in Time focuses on inventory reduction, quality control, waste reduction and smaller production lots. It also discusses the key elements of dependable suppliers, a multiskilled workforce and a total quality control system.