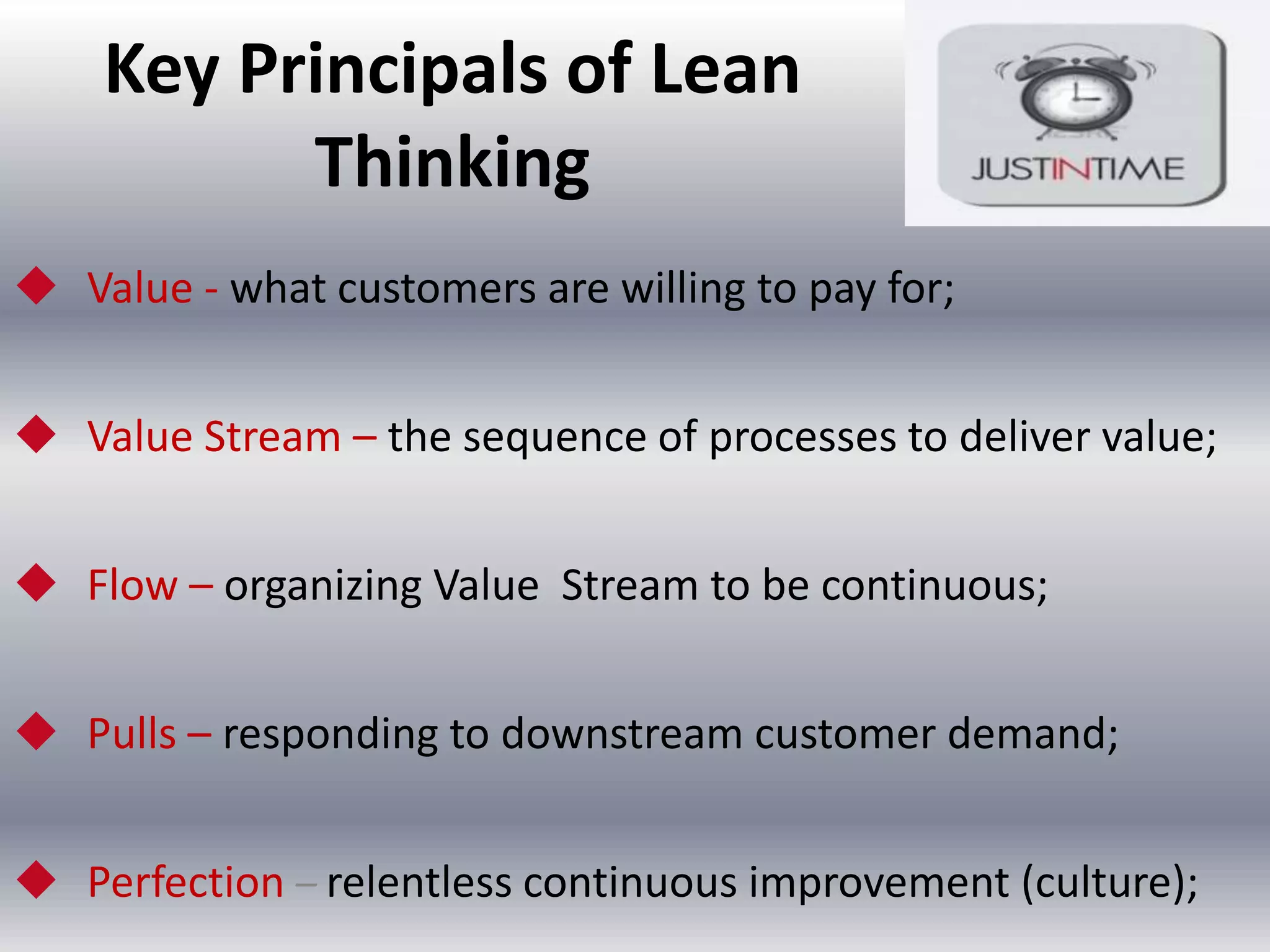

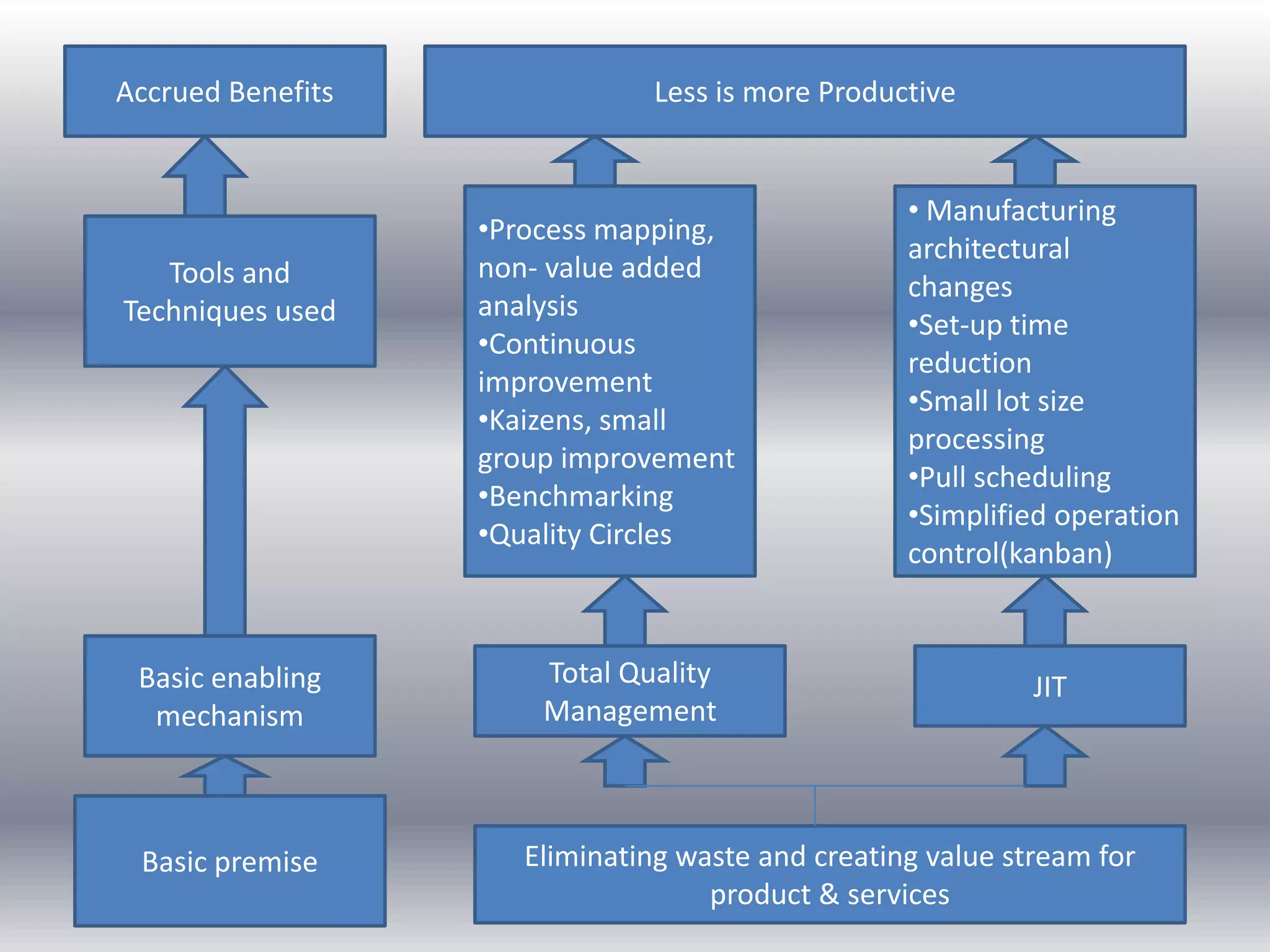

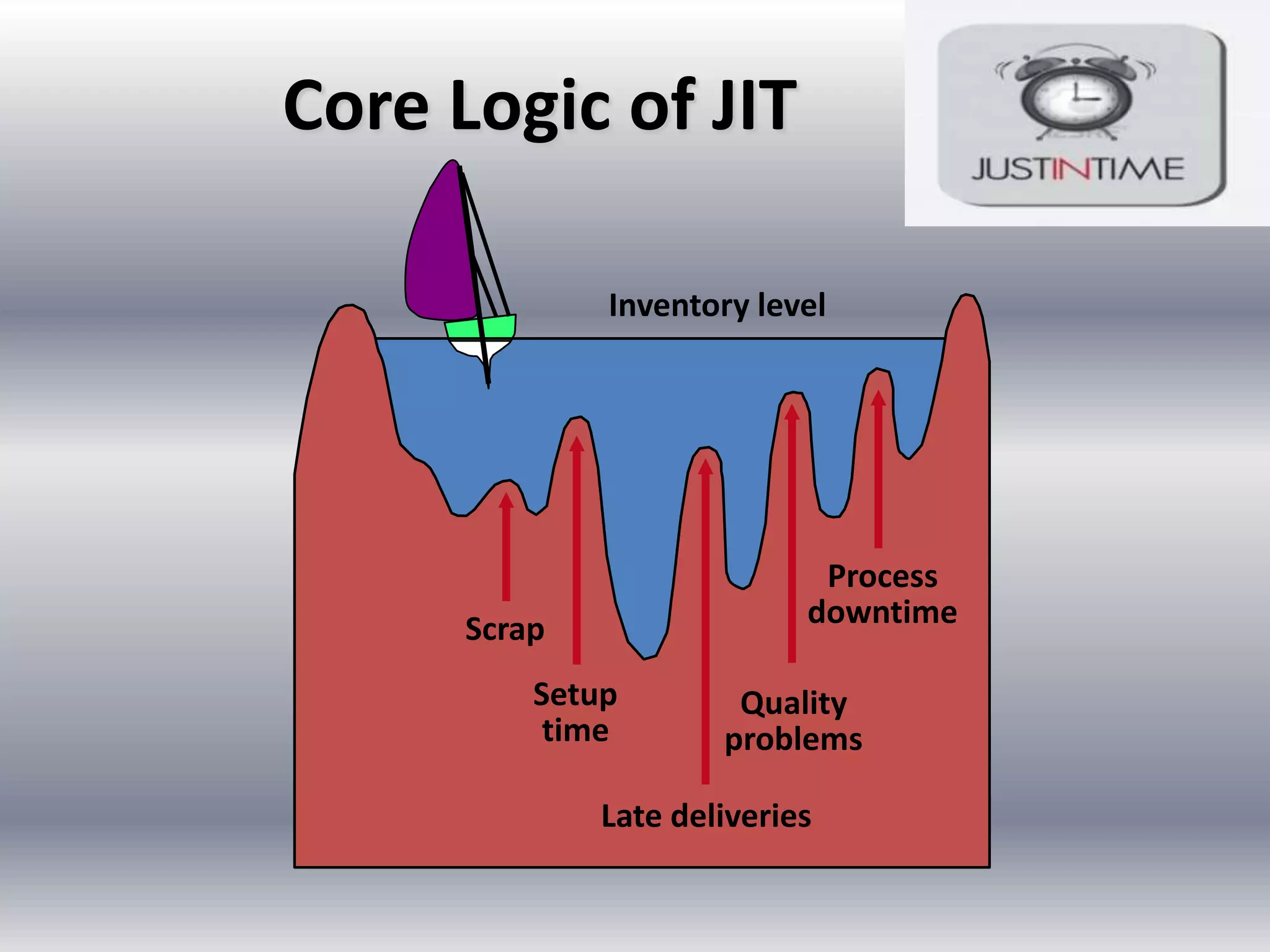

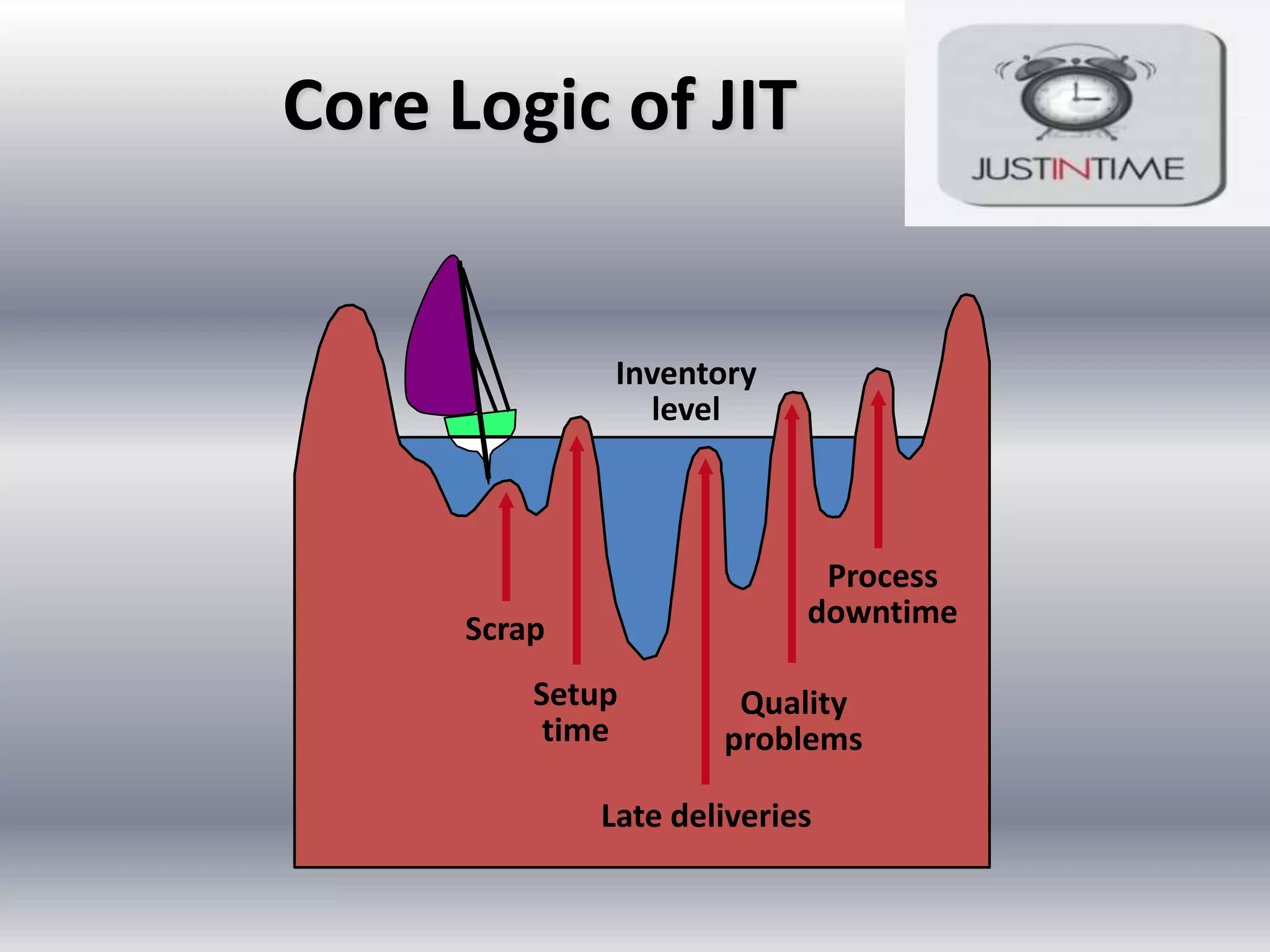

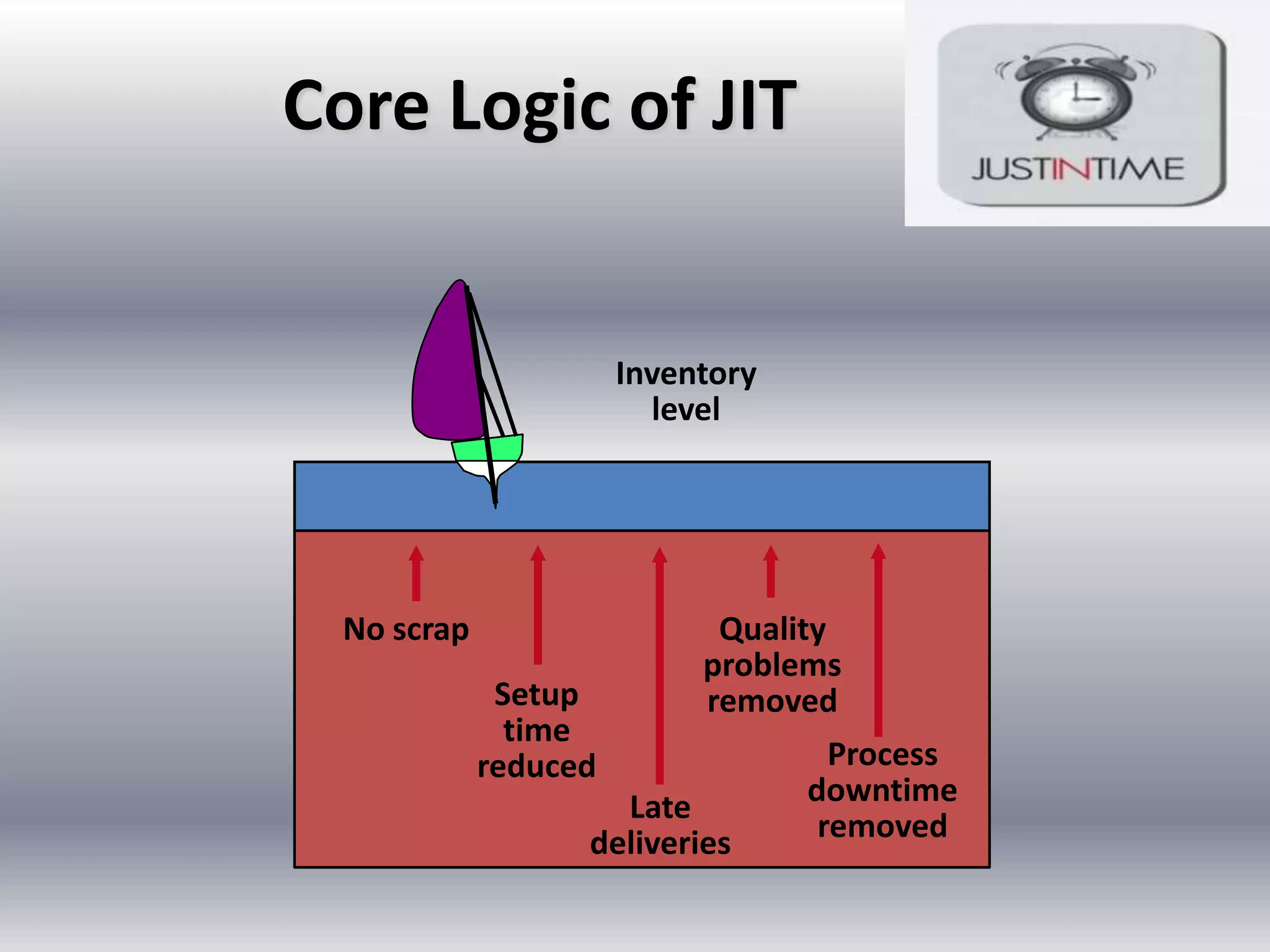

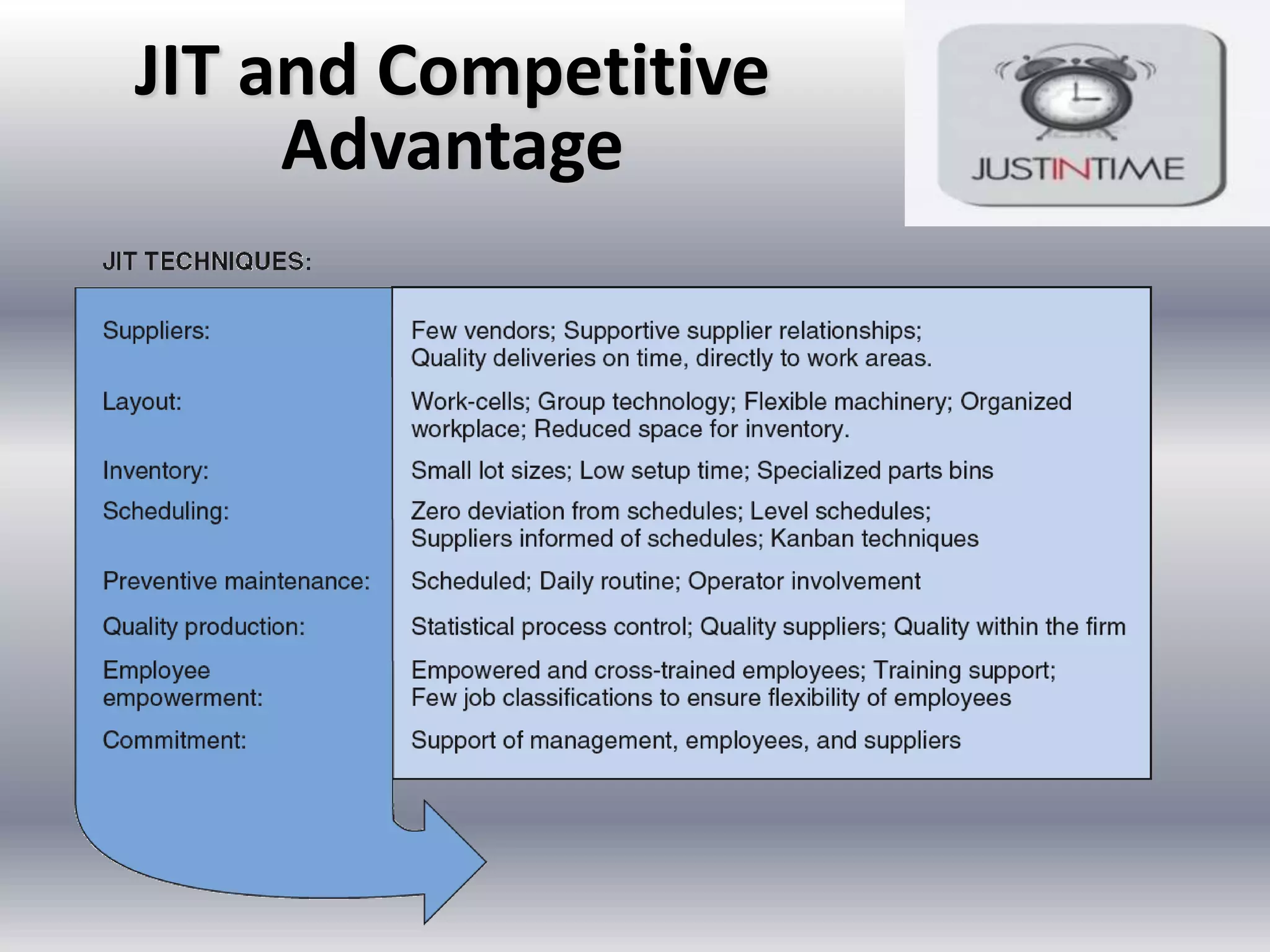

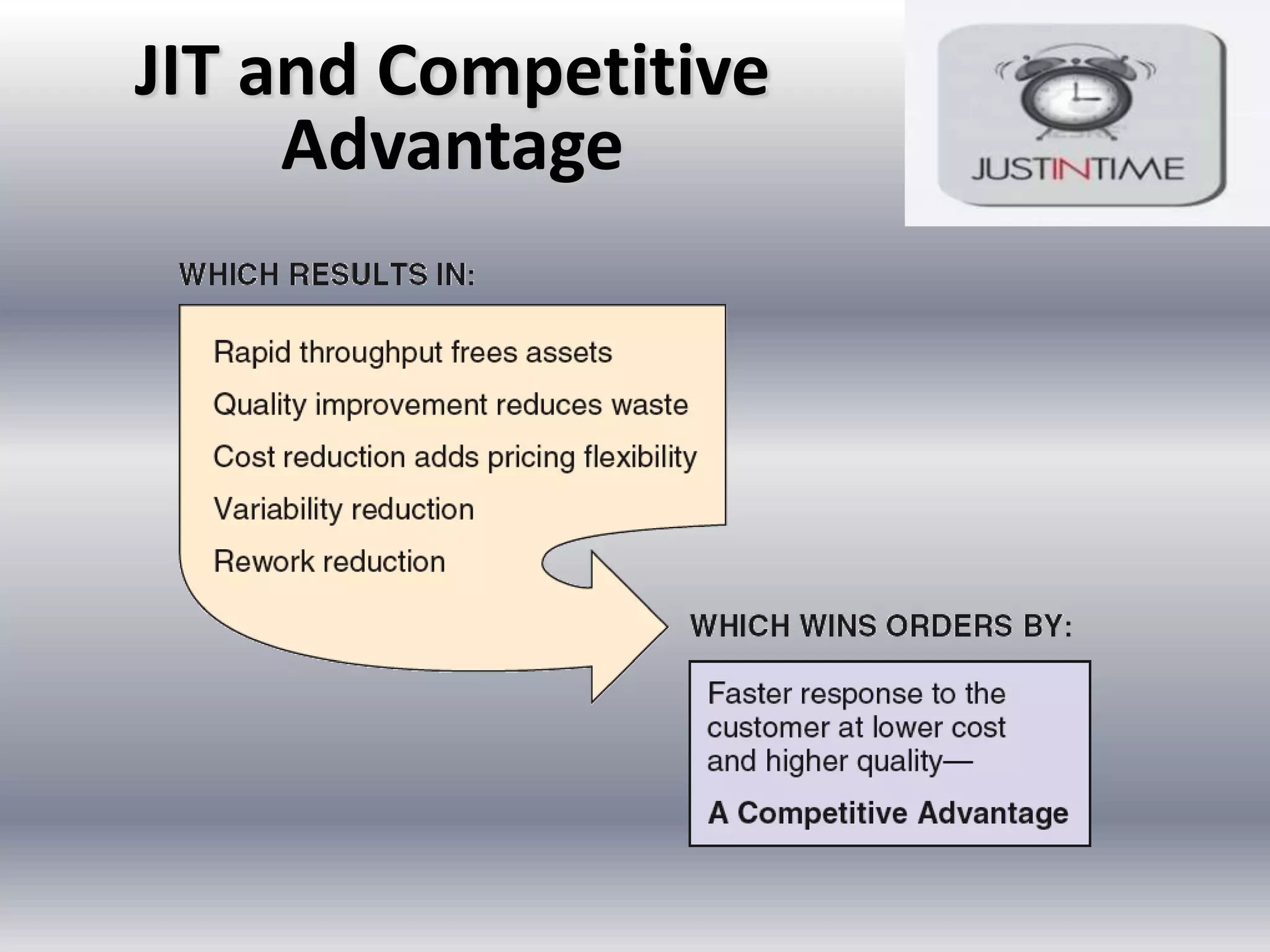

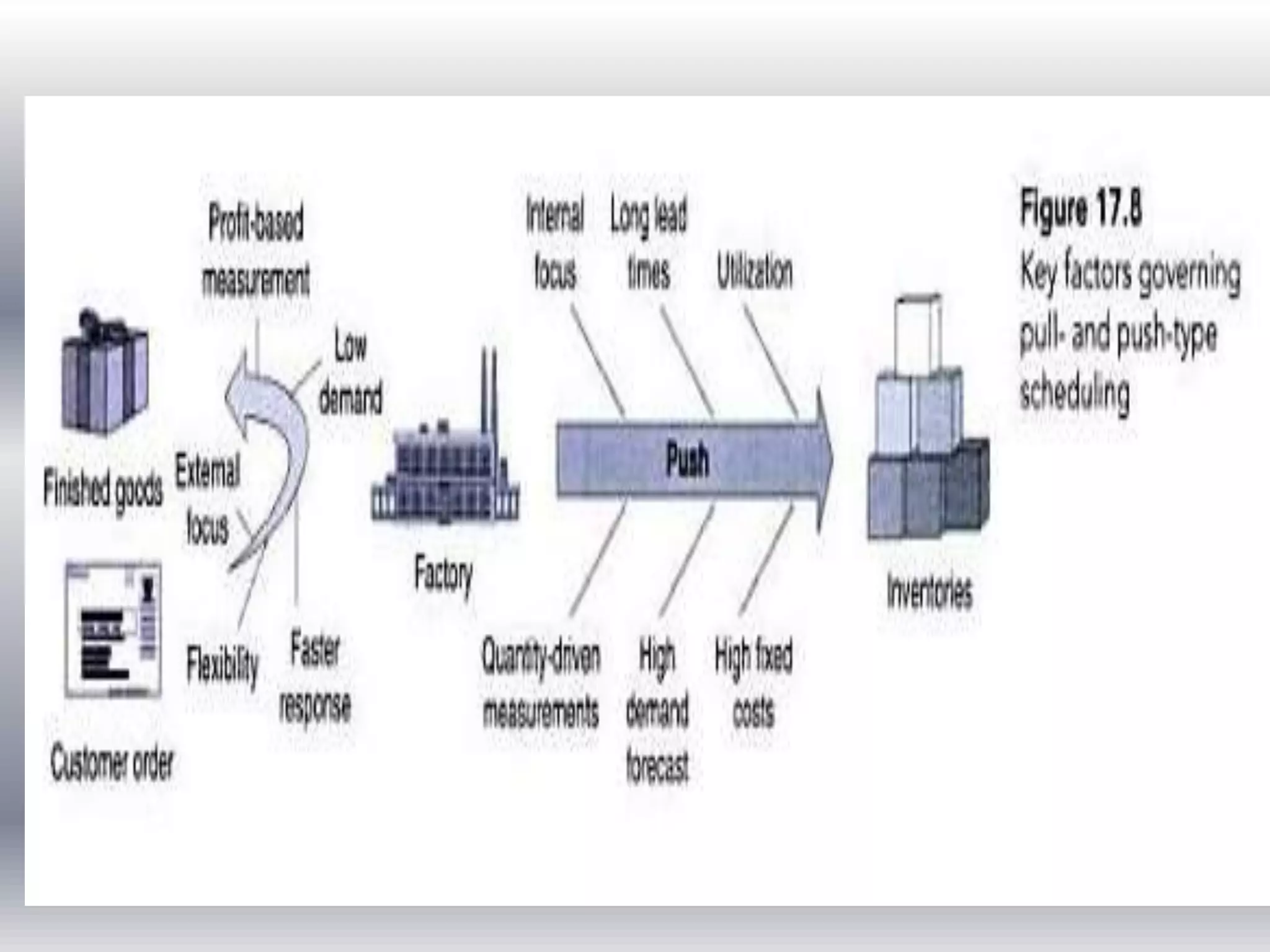

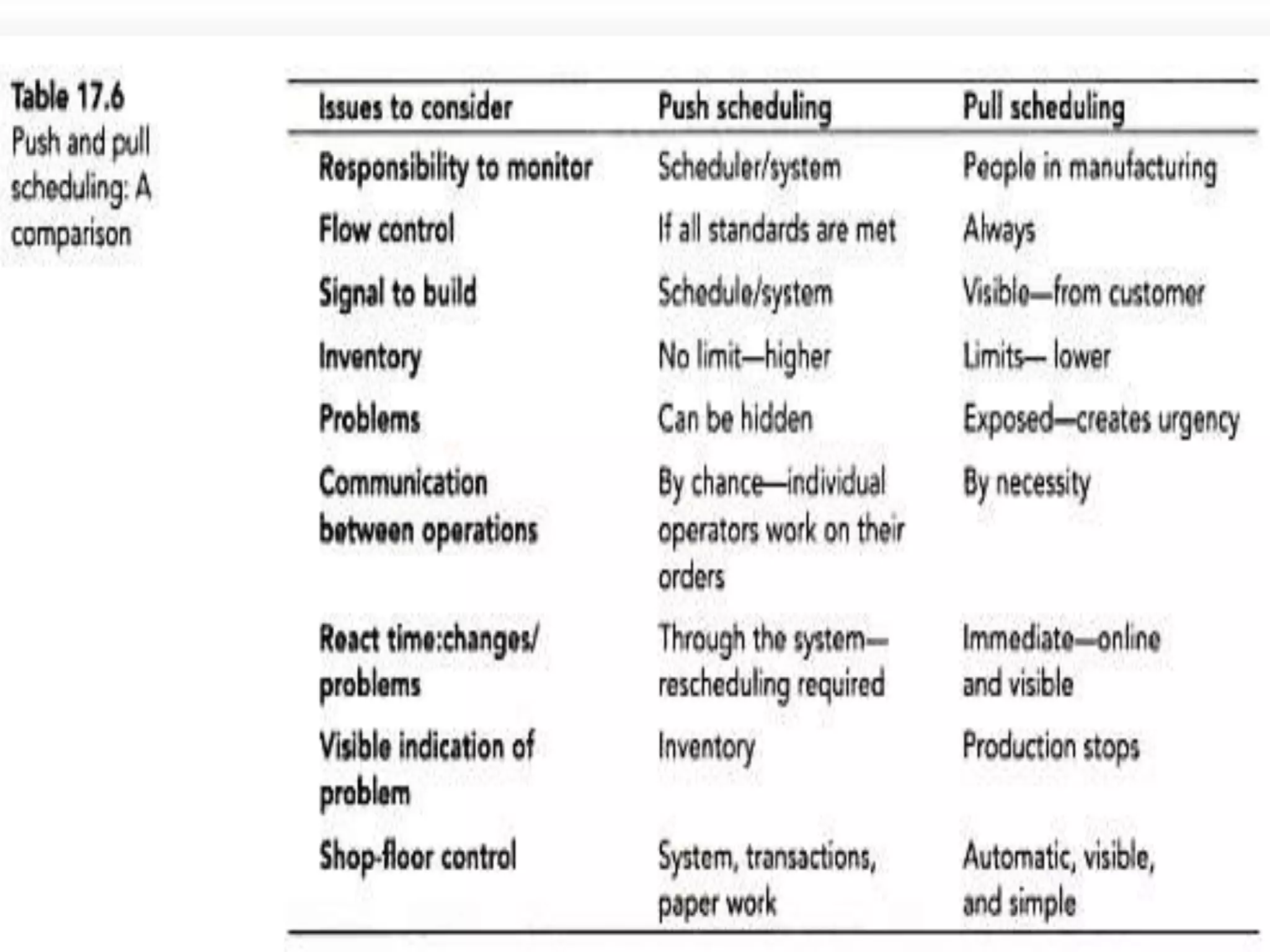

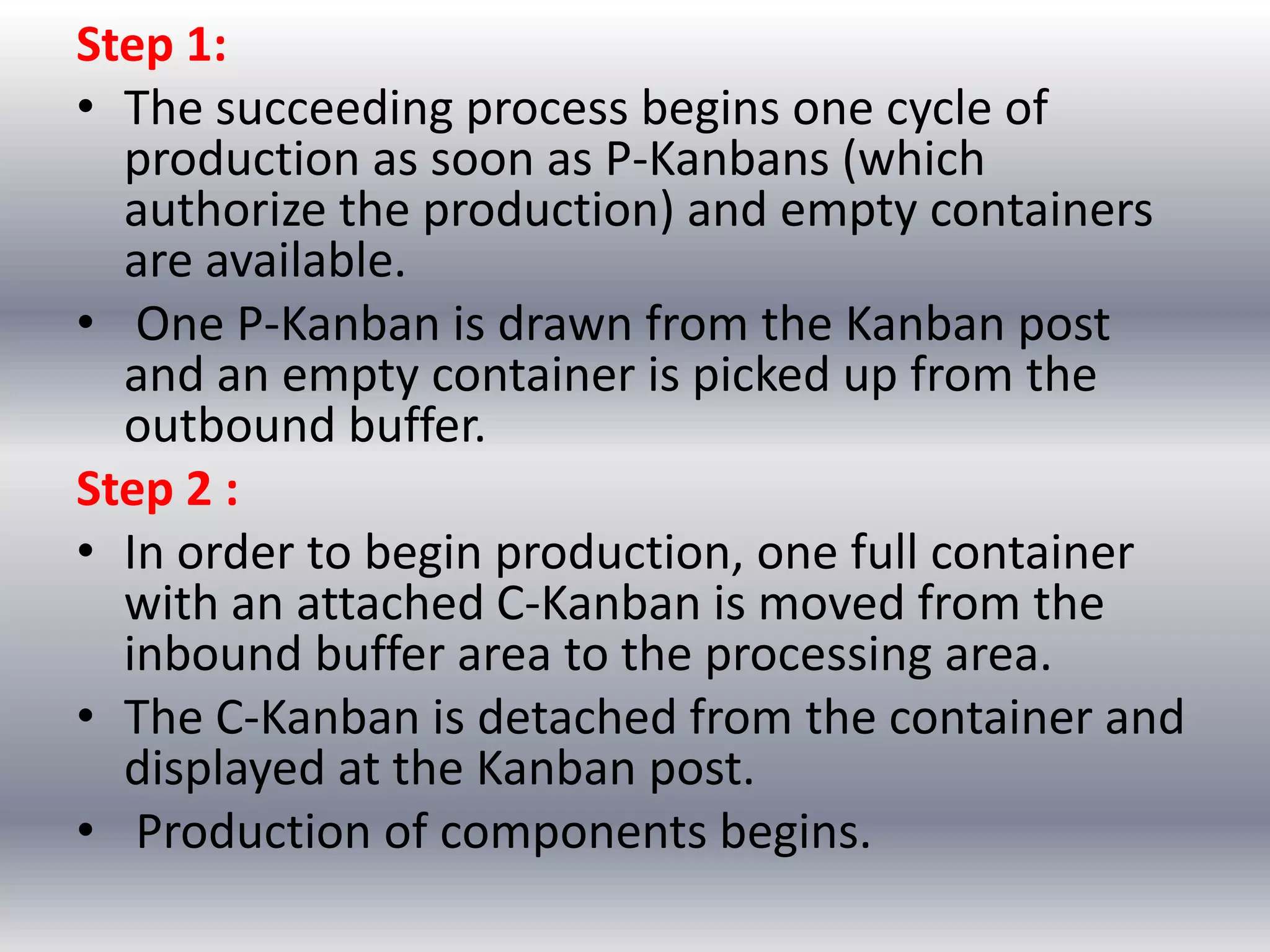

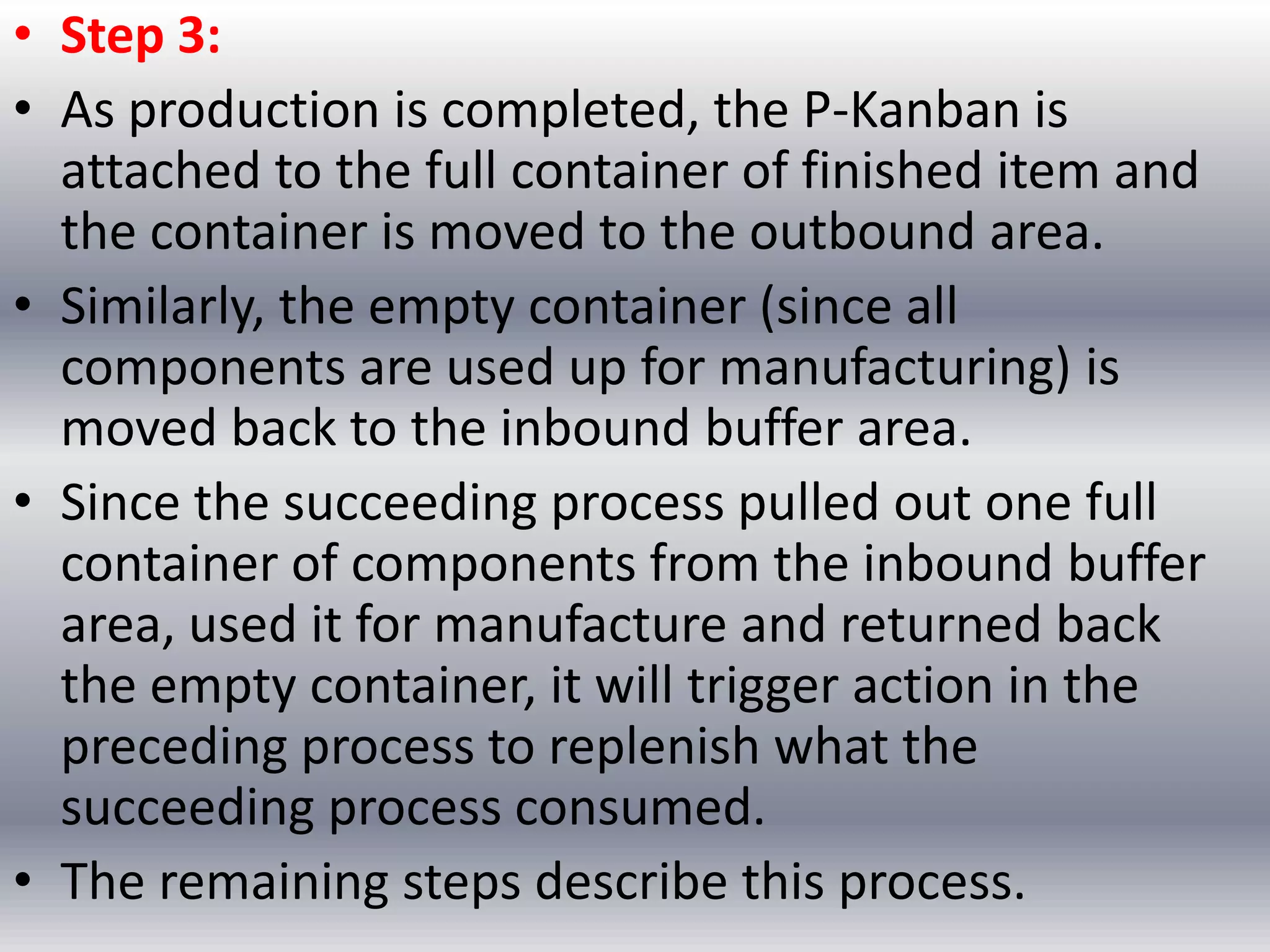

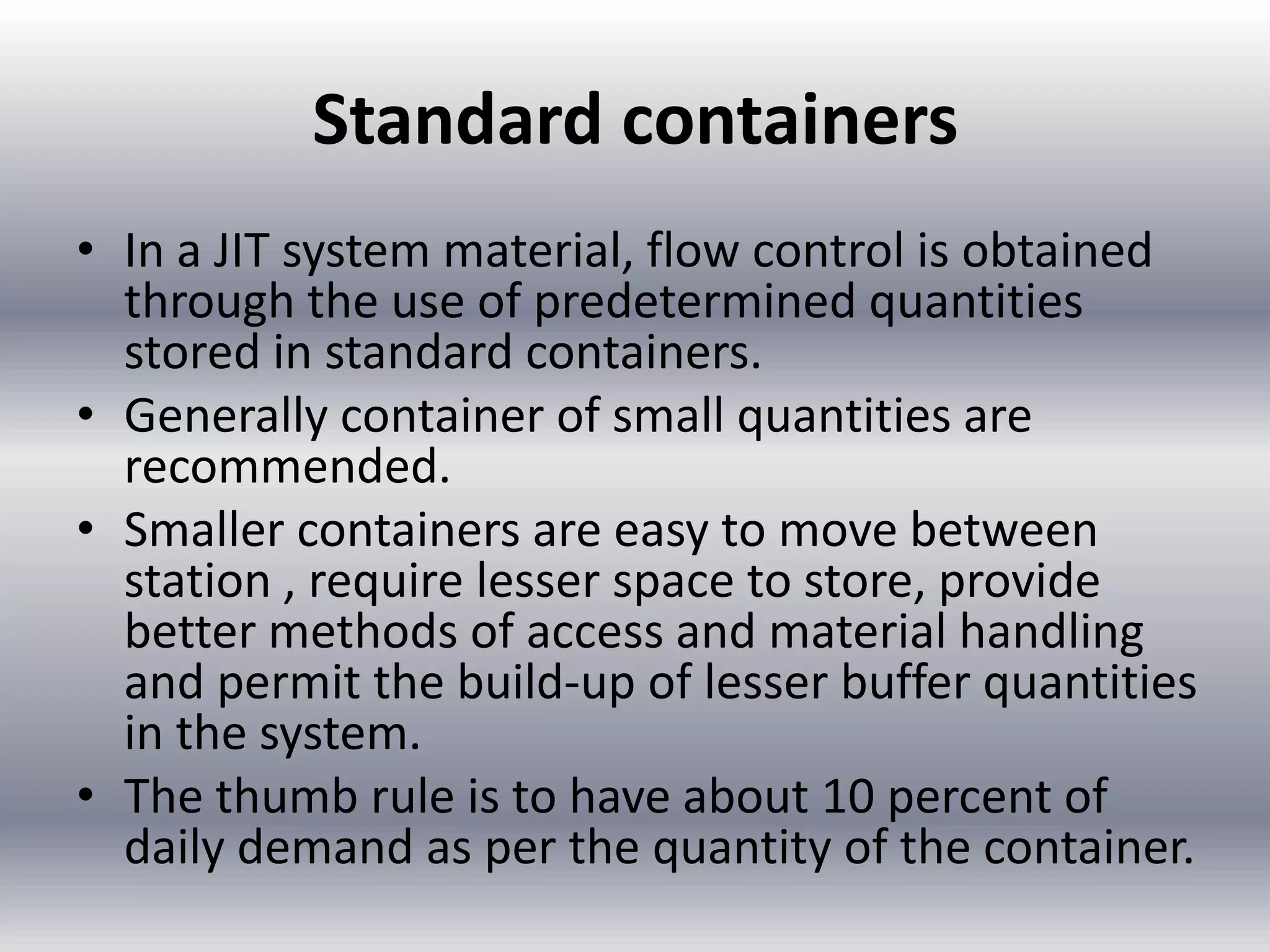

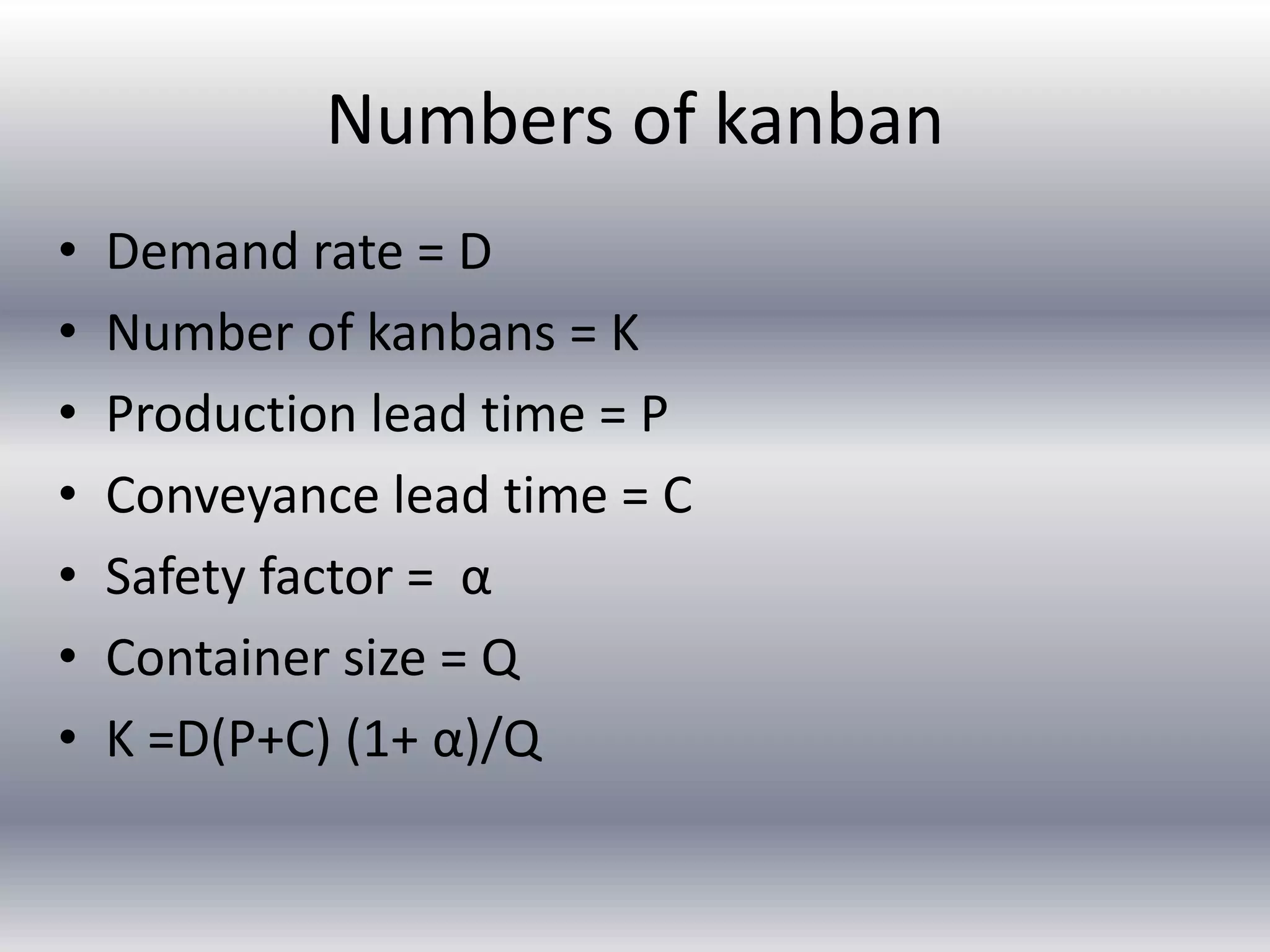

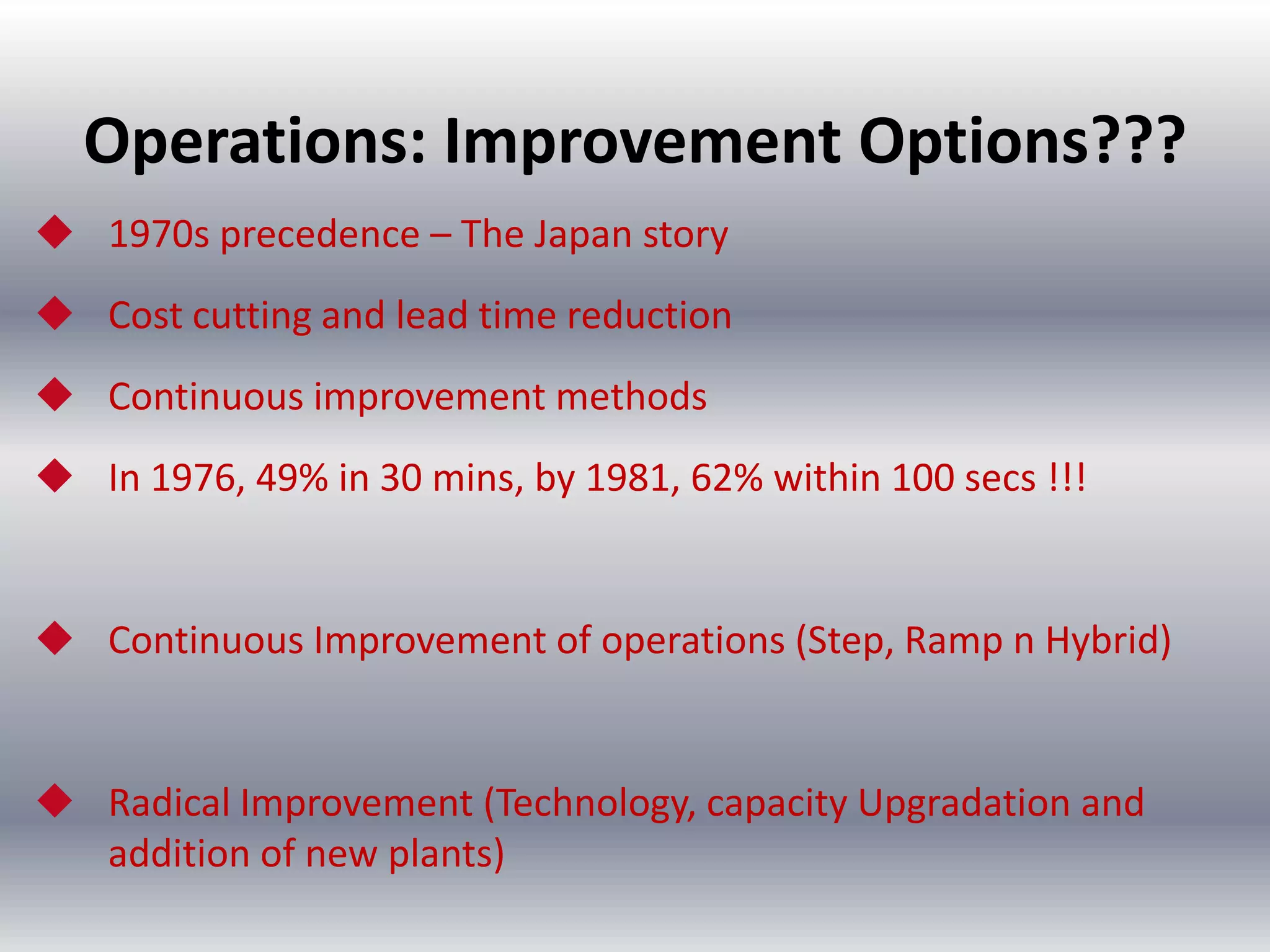

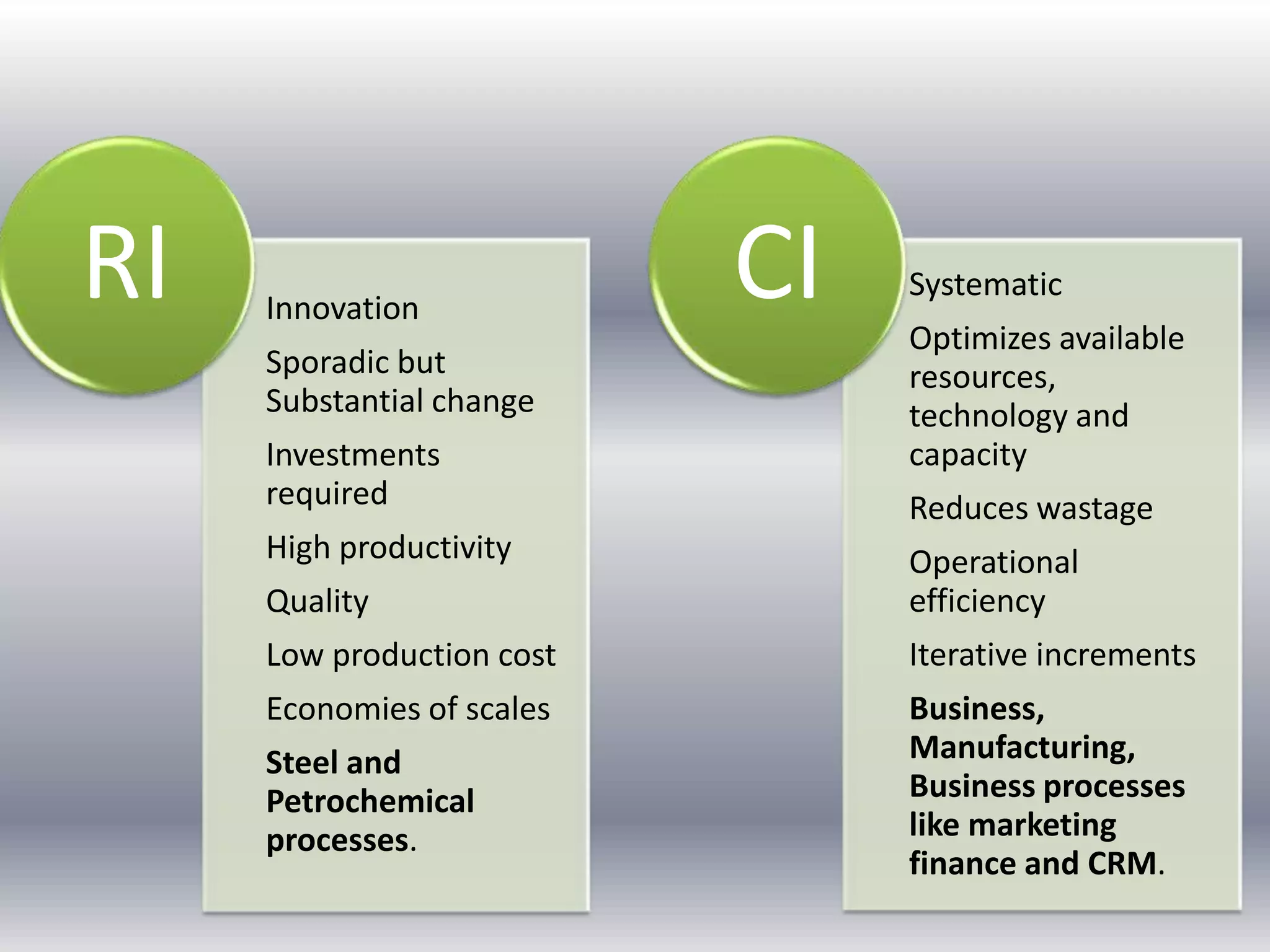

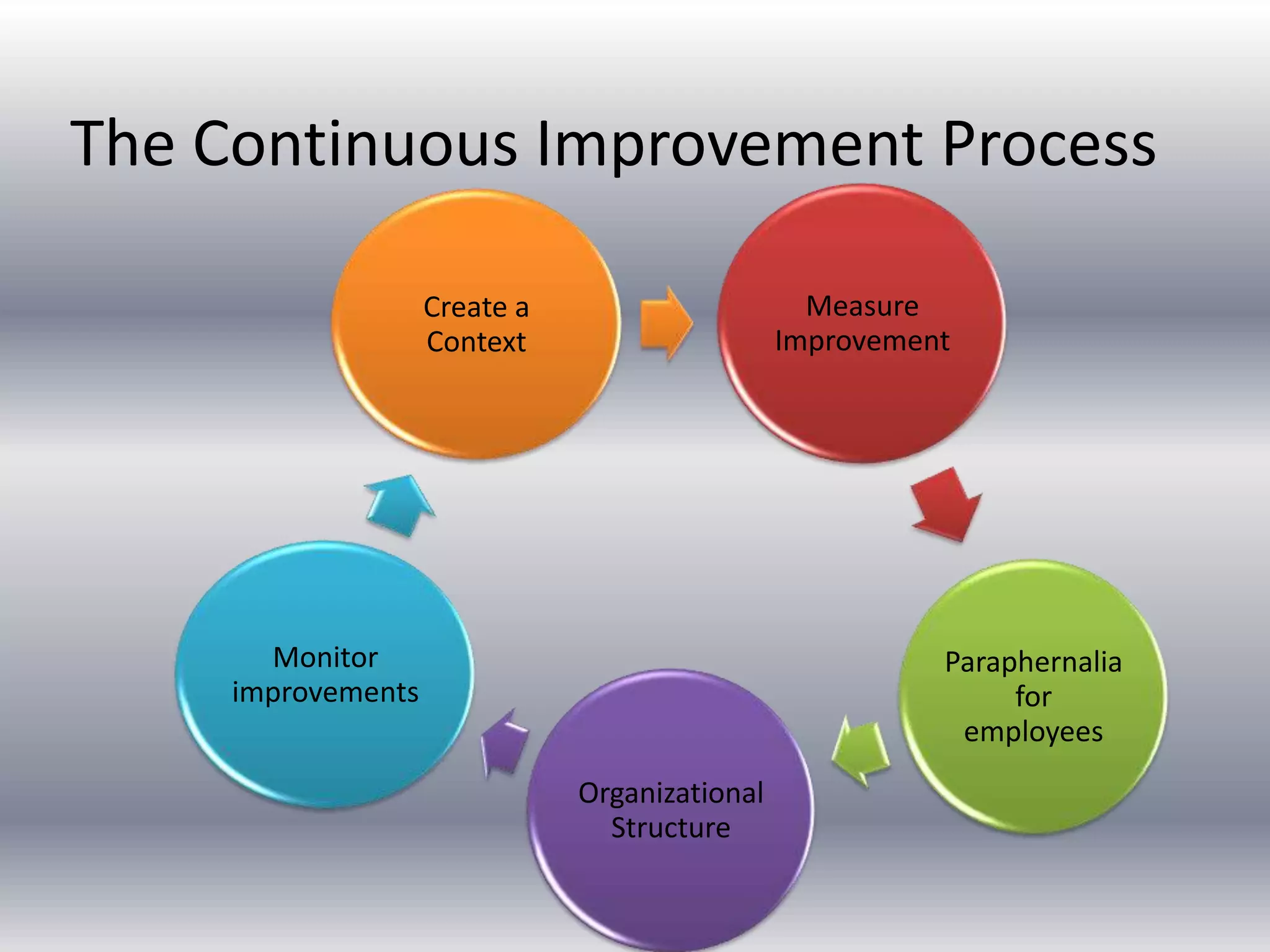

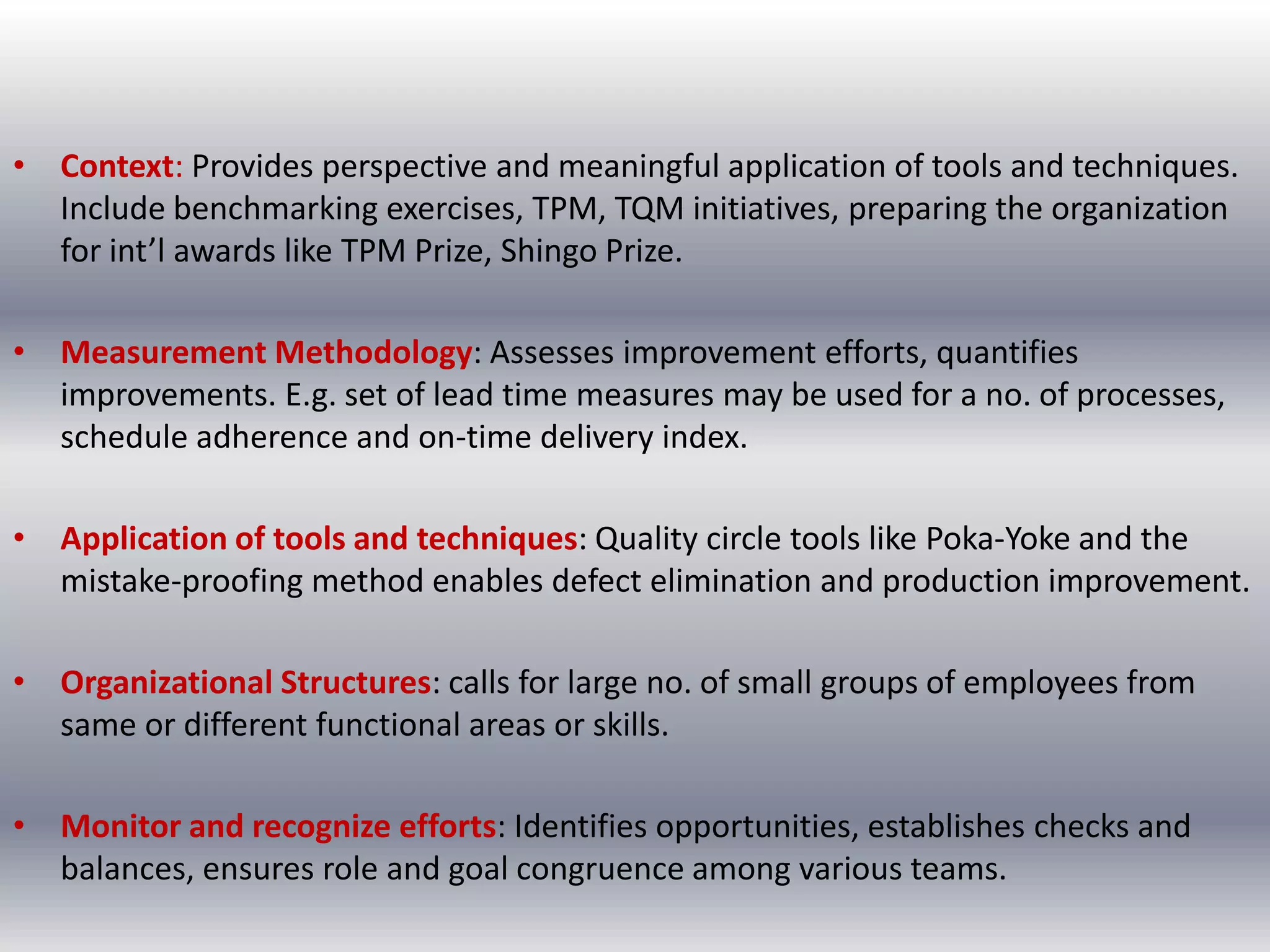

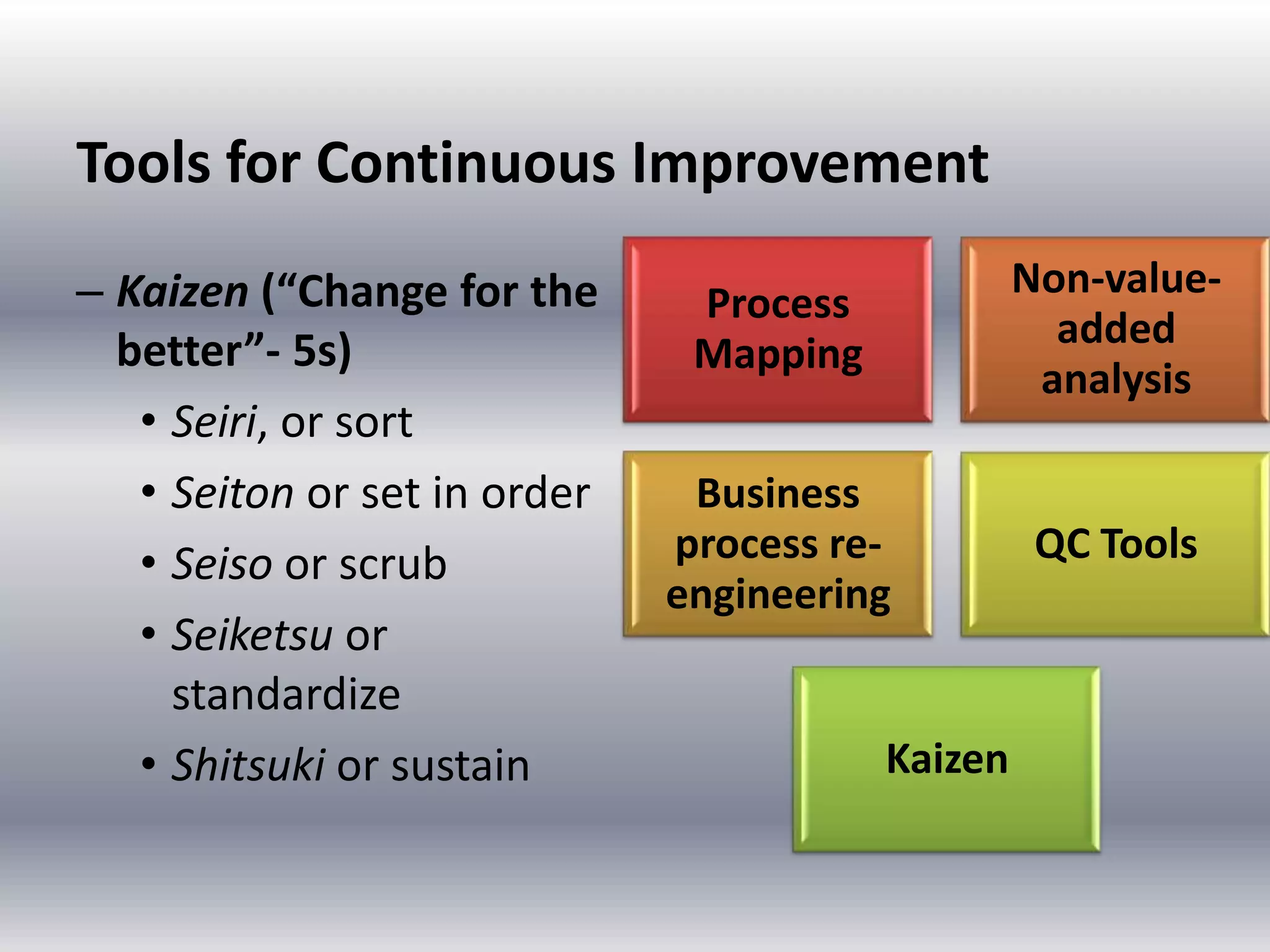

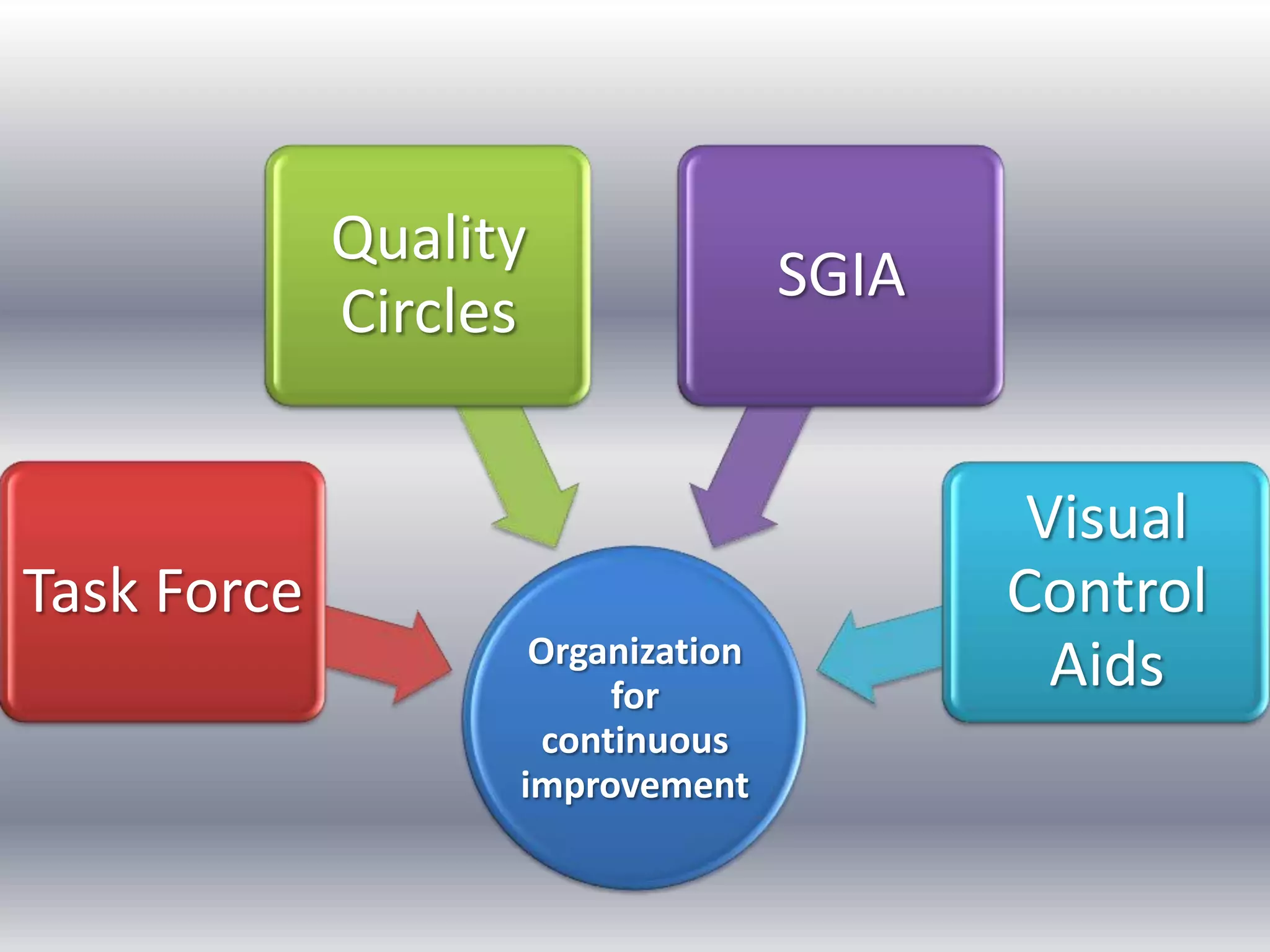

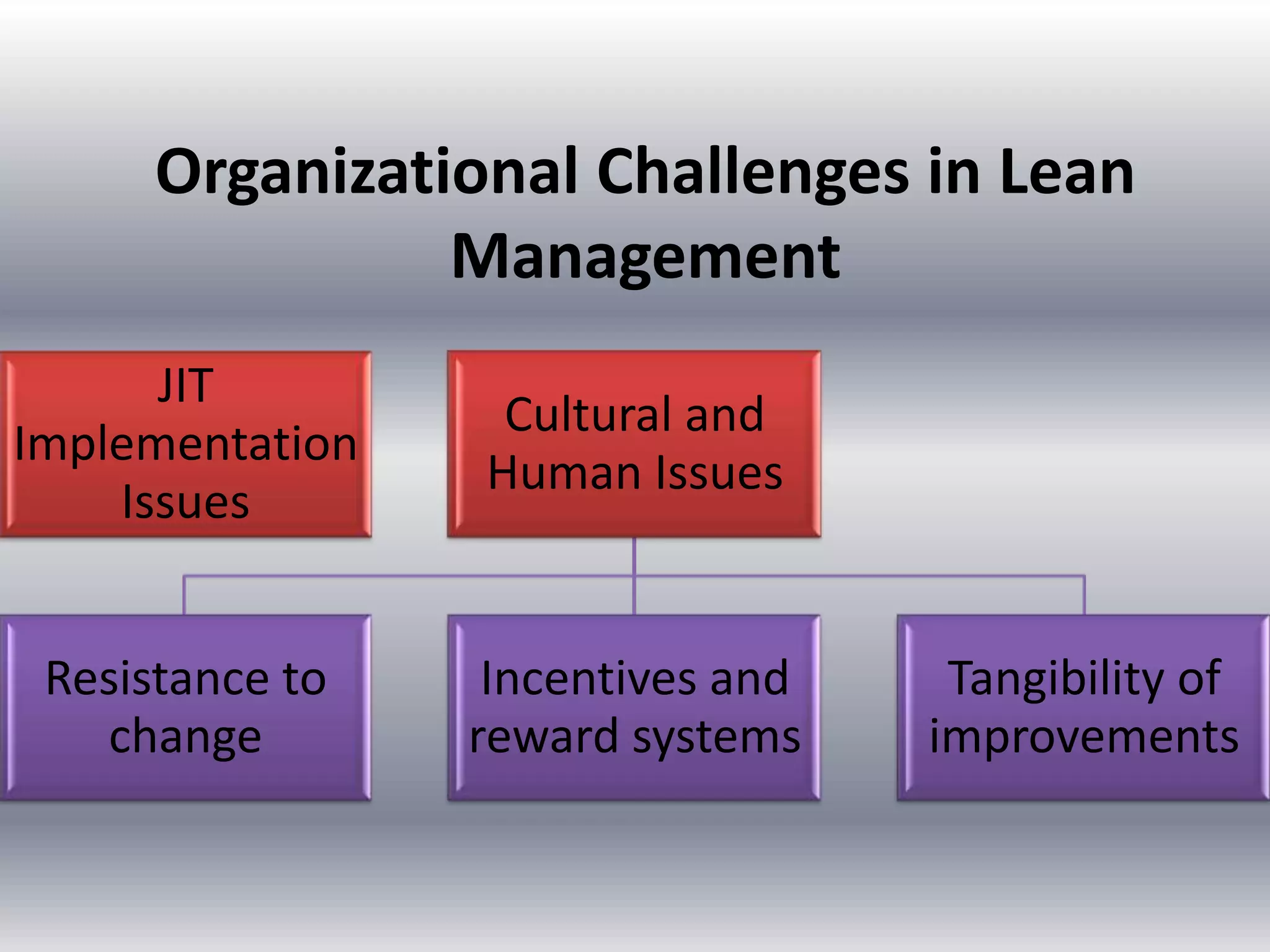

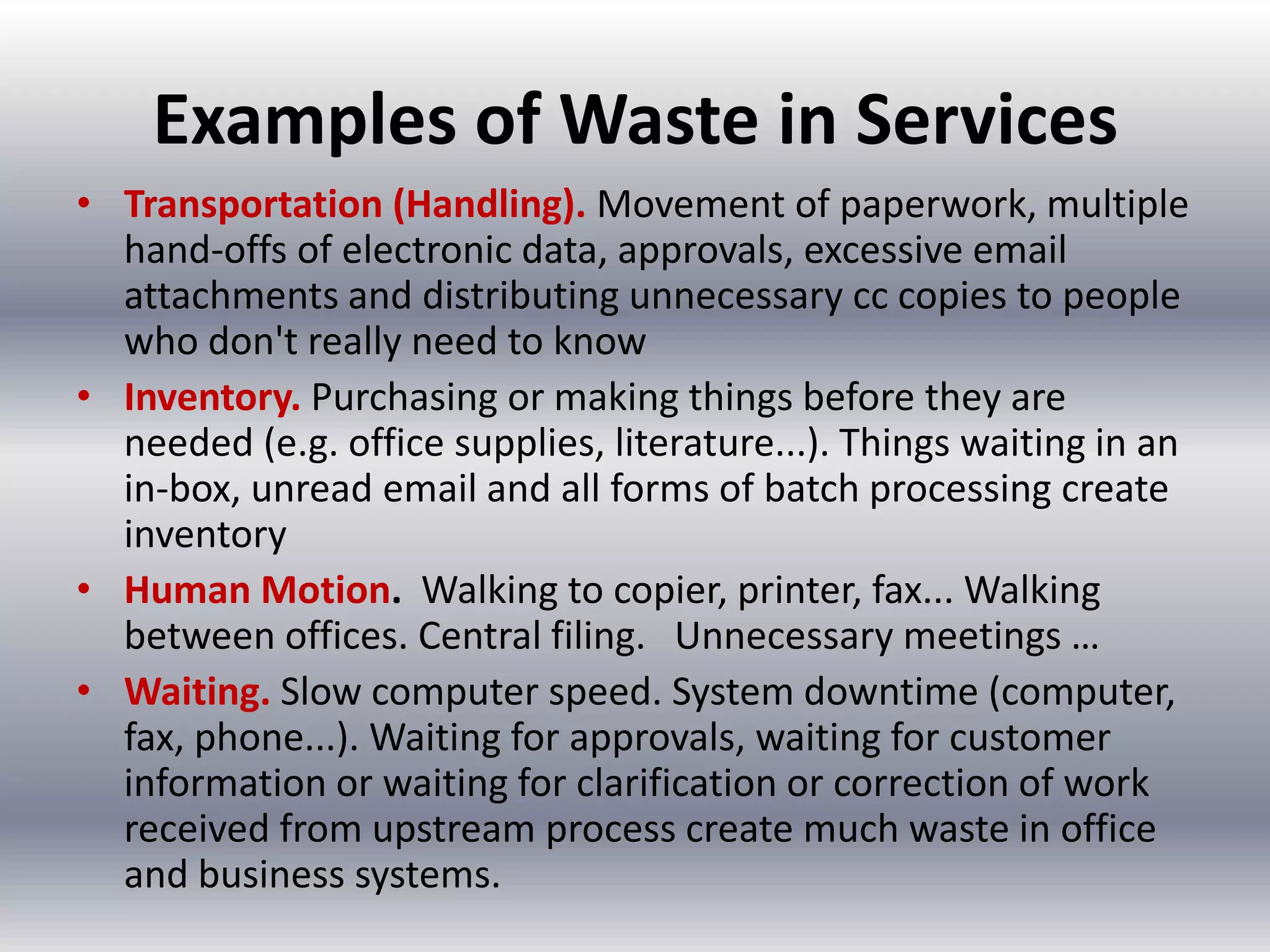

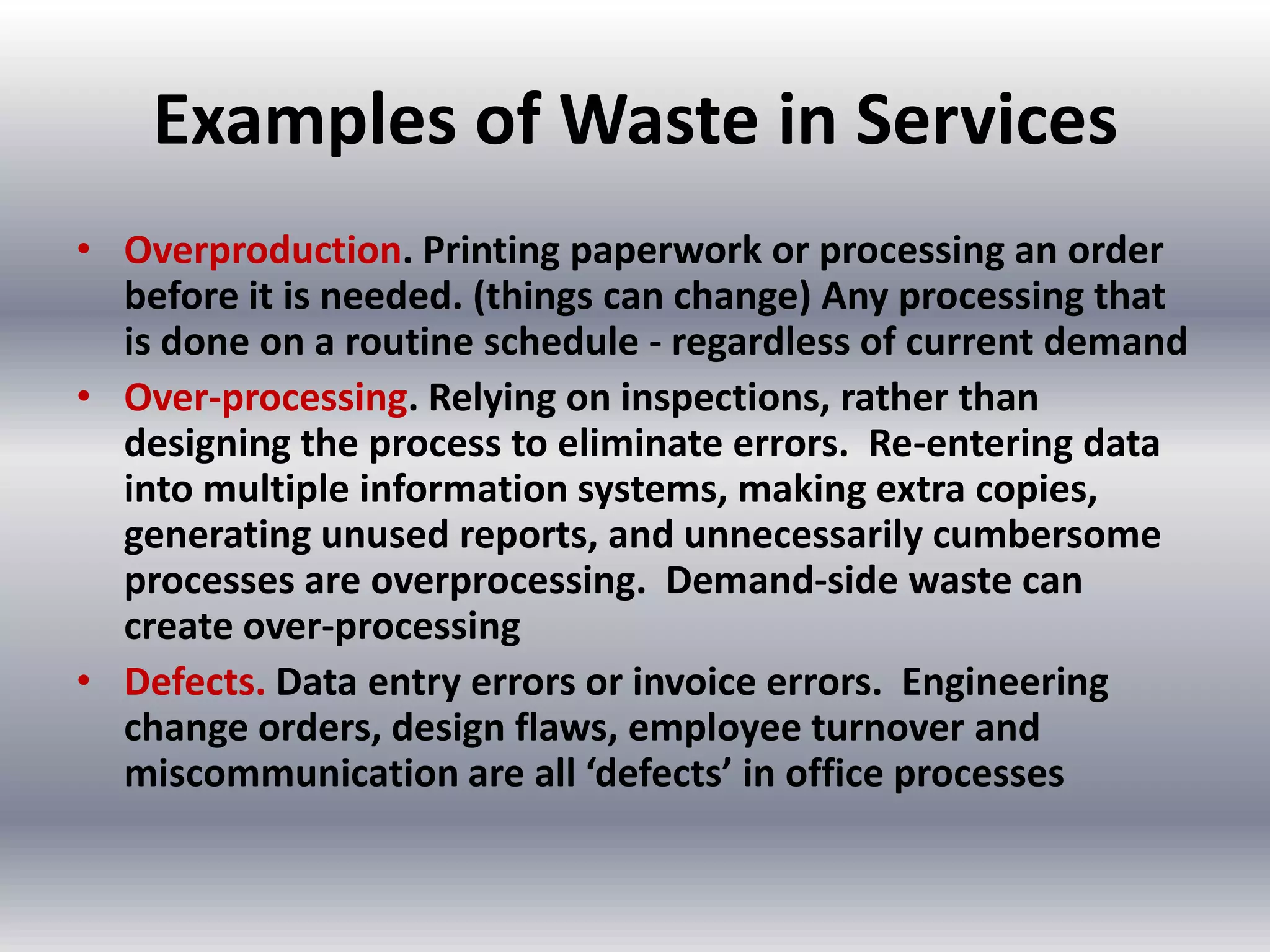

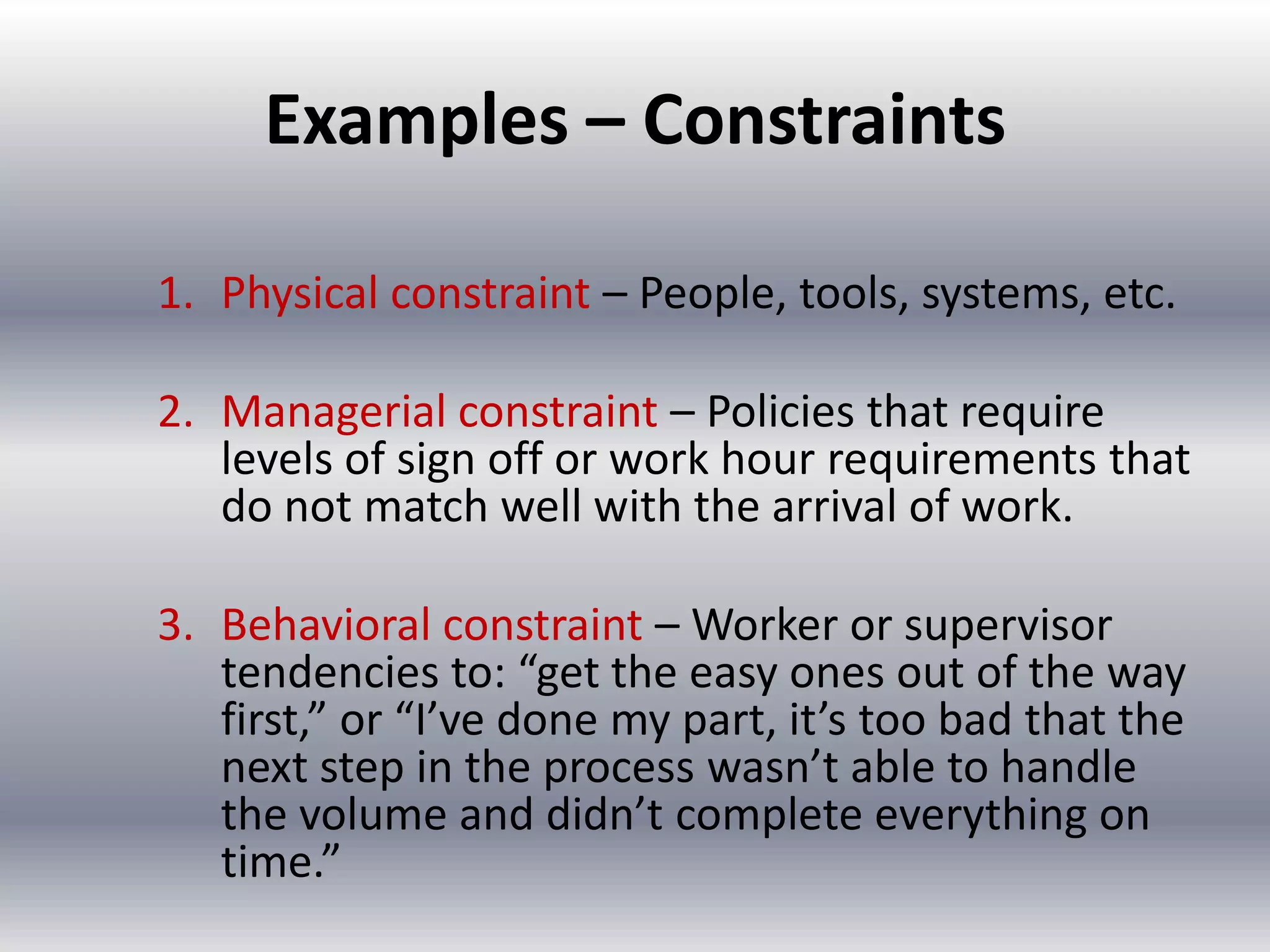

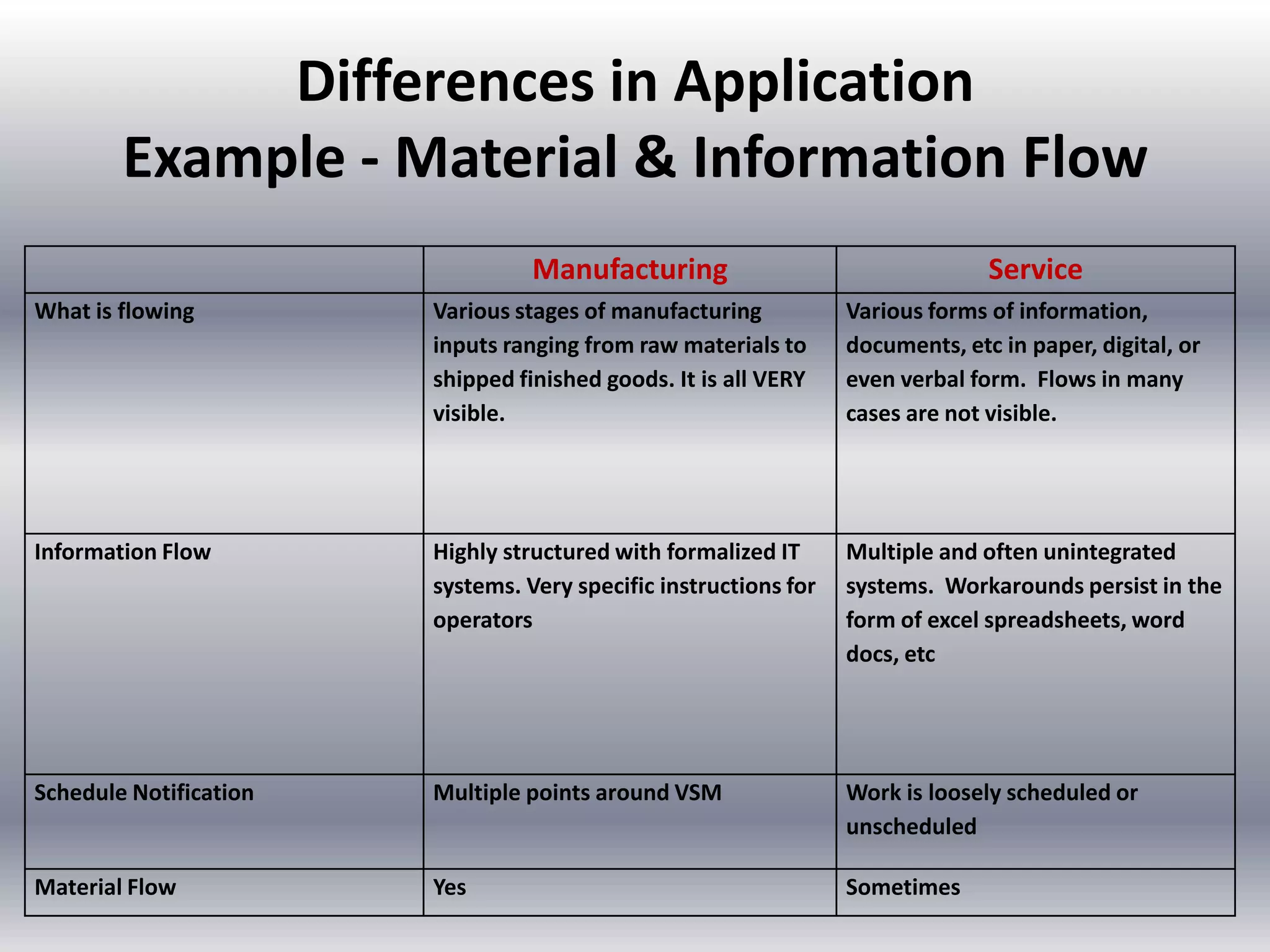

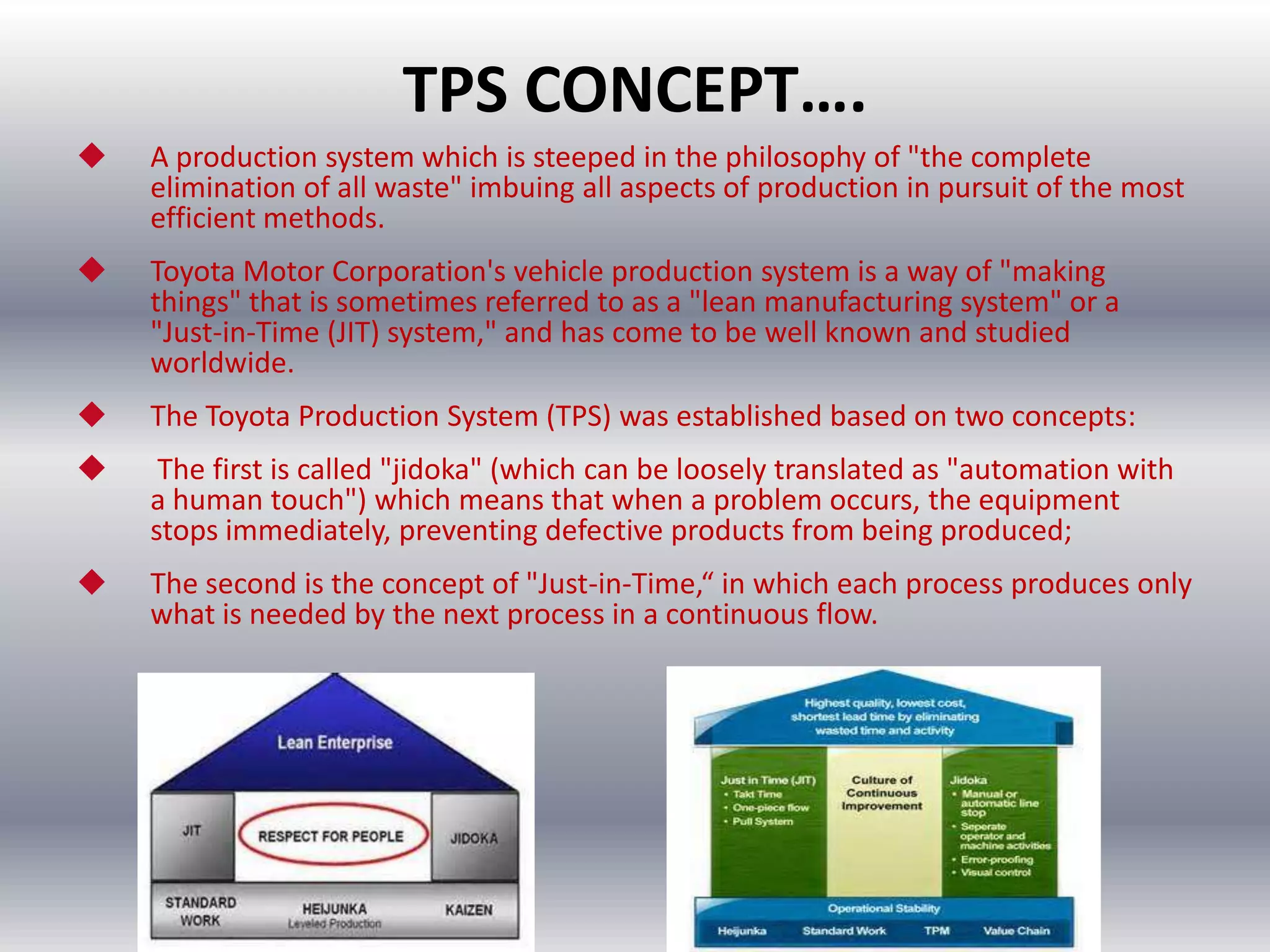

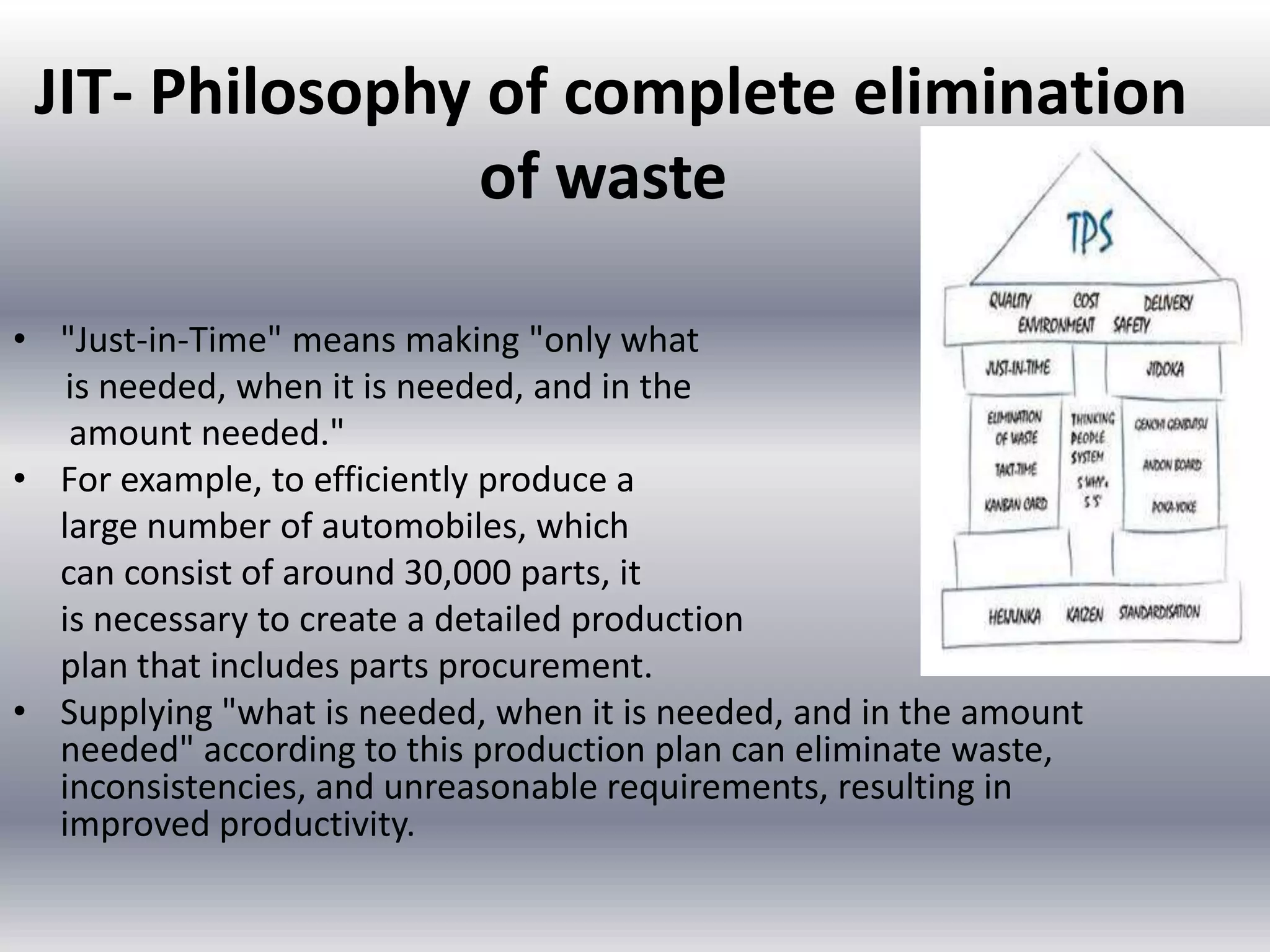

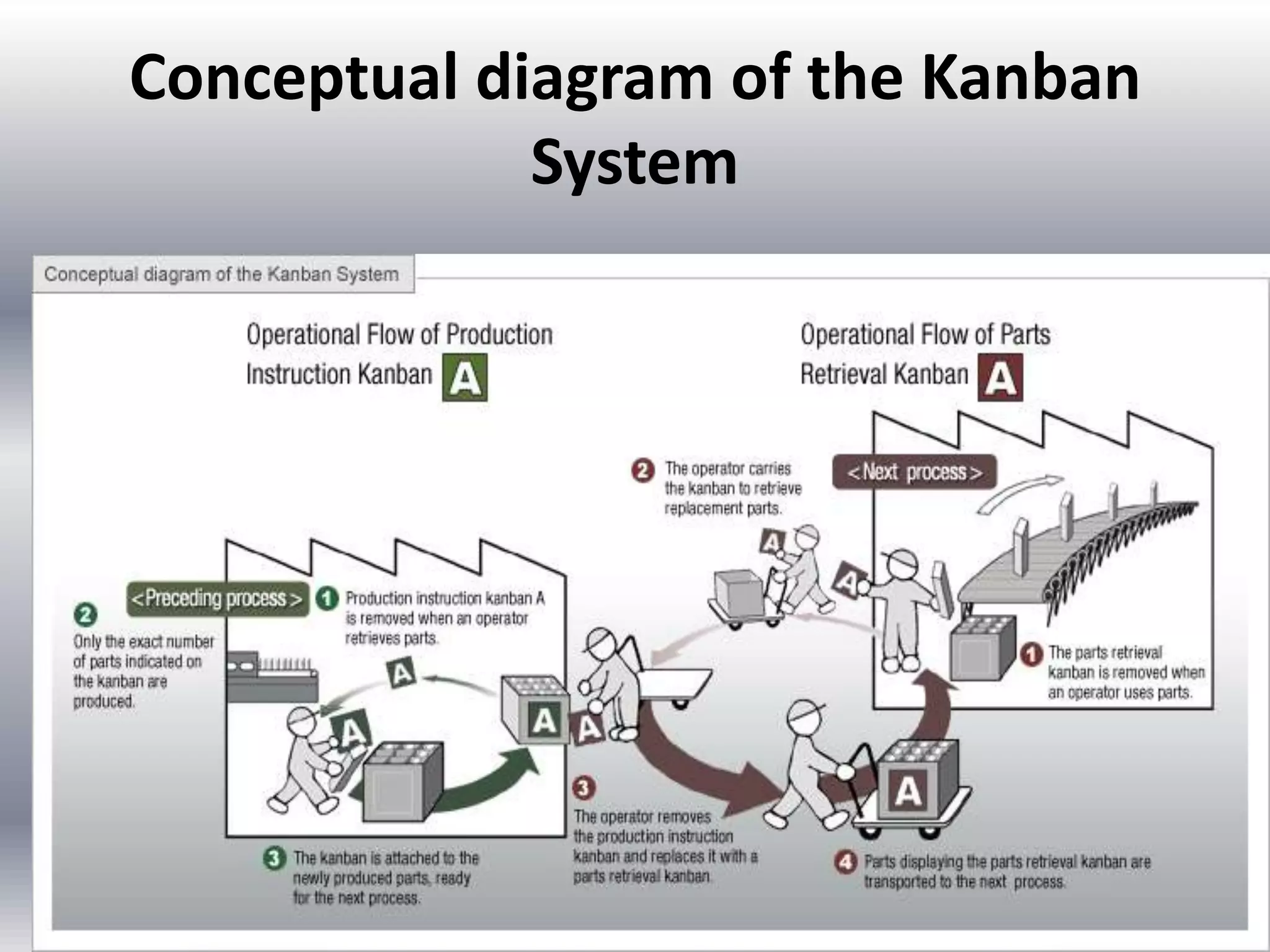

This document provides an overview of lean management. It discusses that lean is a systematic approach to identifying and eliminating waste through continuous improvement. It originated from Japanese automobile manufacturers and has been replicated in other sectors worldwide. The key principles of lean thinking include defining value from the customer's perspective, mapping the value stream, ensuring continuous flow, basing production on customer pull, and pursuing perfection through relentless improvement. Common lean tools and techniques include process mapping, kaizen events, benchmarking, and quality circles. Benefits of lean include reduced waste, setup times, inventory levels, and defects. Just-in-time is a powerful lean strategy that aims to deliver materials to production lines only as needed to improve operations. The document outlines concepts of