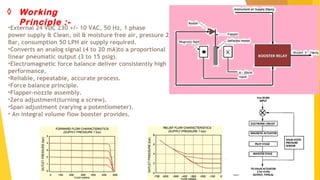

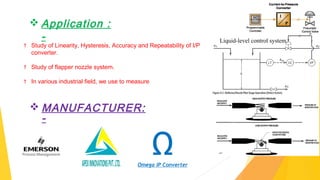

A current to pressure (I/P) converter converts an analog current signal of 4-20 mA to a proportional pneumatic pressure output of 3-15 psig. It is used in pneumatic control systems to translate electrical control signals into precise, repeatable pressure values that can control pneumatic actuators. The I/P converter has a rugged zinc cast housing and requires an external power supply and compressed air source. It works using an electromagnetic force balance principle with a flapper-nozzle assembly, and has zero and span adjustments for field calibration. I/P converters are commonly used in industrial processes to control levels, flows, pressures, temperatures and other process variables.