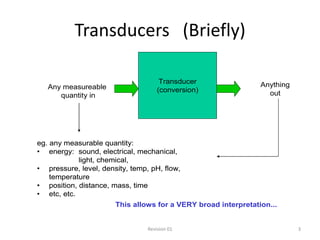

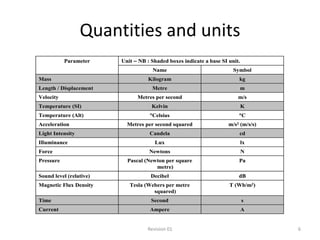

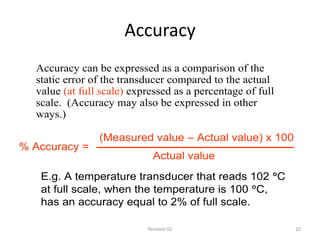

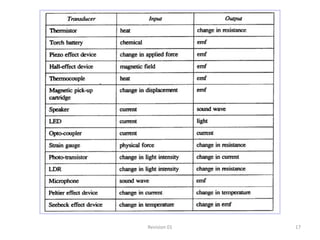

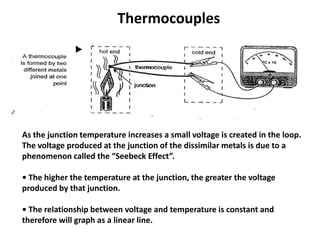

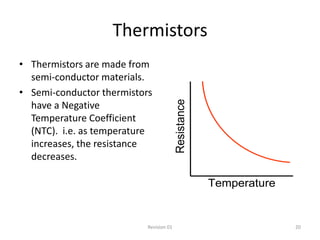

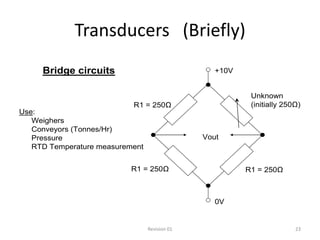

Transducers convert one form of energy to another. They are defined as devices that convert an input signal of one form to an output signal of another form. Transducers can measure many quantities including energy, pressure, temperature, position, and more. Common transducers include thermocouples, thermistors, strain gauges, and magnetic pickups. Transducer parameters that are important to consider include sensitivity, range, span, linearity, hysteresis, accuracy, and precision.