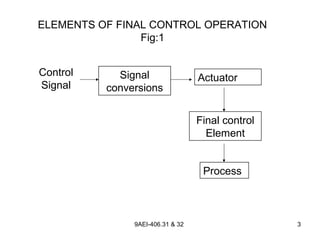

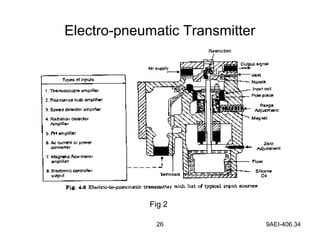

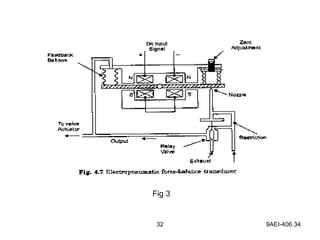

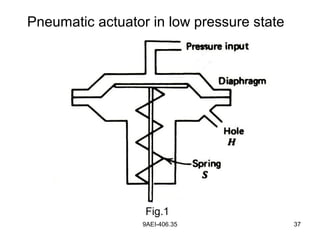

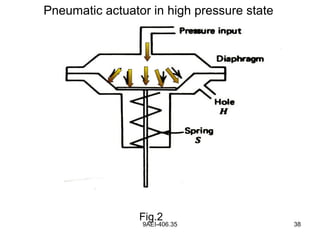

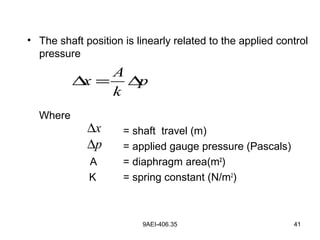

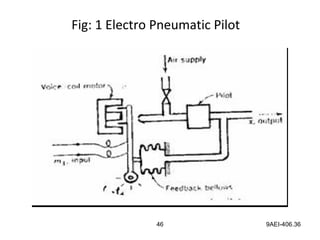

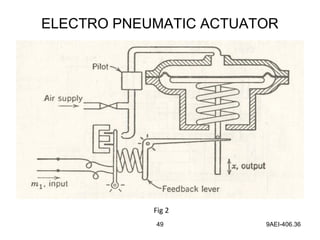

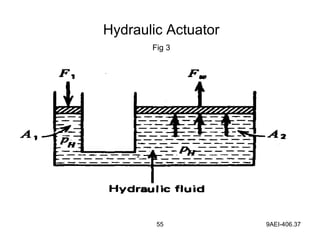

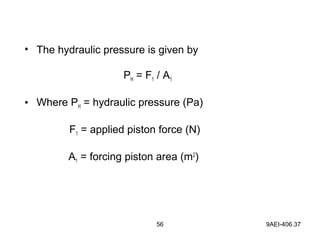

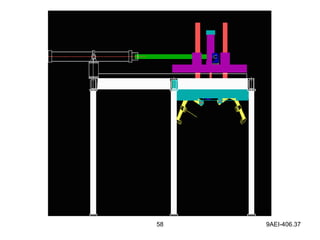

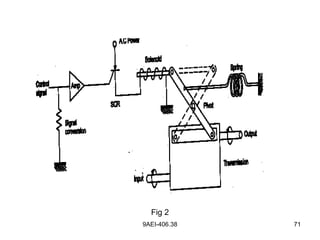

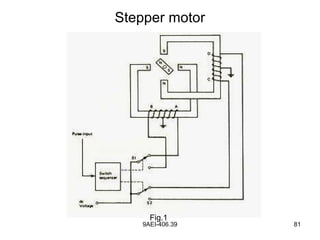

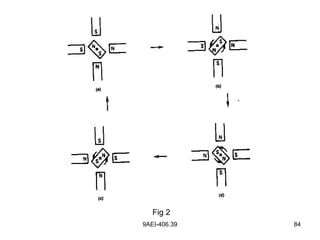

The document describes the basic principles and components of a final control element. It discusses how a process controller's output signal is converted by various components into proportional action on the process. It identifies the typical elements as the control signal, signal conversions, actuator, and final control element. Signal conversions modify the control signal to interface with the actuator. The actuator then translates the converted signal into physical movement of the final control element, which directly influences the process variable. Common types of actuators include pneumatic, hydraulic, electro-pneumatic, and electric motor actuators.