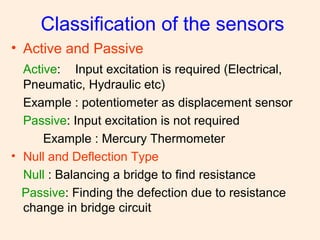

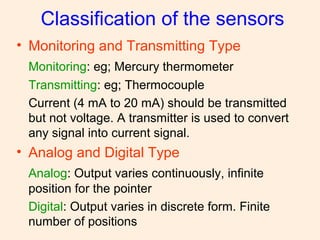

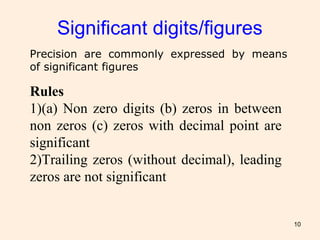

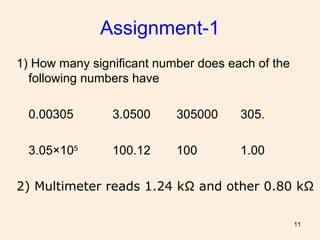

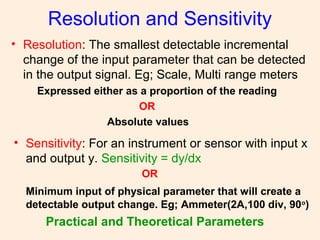

The document discusses advanced instrumentation concepts, including sensor types, transducers, signal conditioning, and biomedical instrumentation. It details classifications of sensors, static characteristics, measurement accuracy, and common errors in measurement processes. Additionally, it covers essential topics like calibration, hysteresis, linearity, and the effects of various factors on measuring instruments.

![18

Hysteresis

It refers to the difference

between upscale sequence

of calibration and downscale

sequence of calibration

he=({y}upscale-{y}downscale)x=x1

Hysteresis error = [he(max)/FSOR] ×100

FSOR : Full Scale Output Reading

Fig. Internal force verses extension

of a rubber band follows

hysteresis. External force is in

opposition to internal force

E.g. Potentiometer used as

displacement sensor with

significant losses](https://image.slidesharecdn.com/introductiontosensors-170114034928/85/Introduction-to-sensors-18-320.jpg)