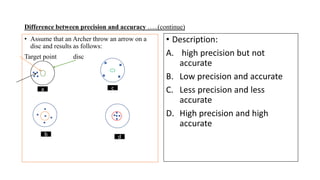

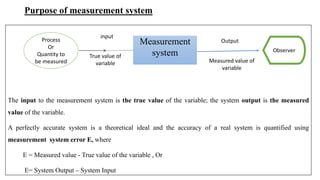

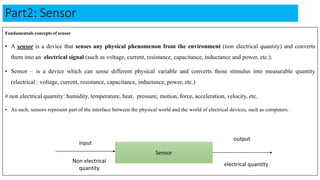

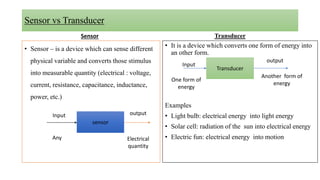

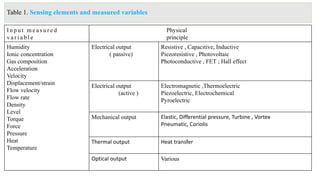

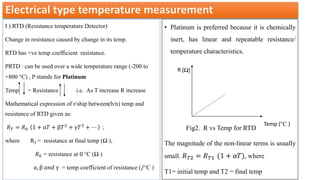

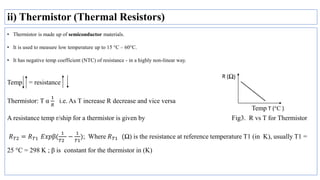

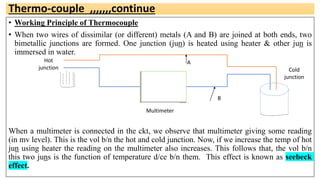

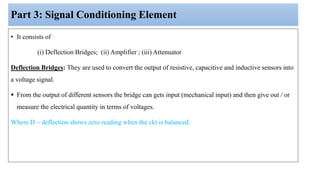

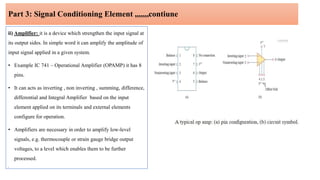

This document provides an overview of an introduction to instrumentation course, including its objectives, contents, and key concepts. The course aims to discuss measurement systems, sensors, signal conditioning circuits, conversion elements, and output devices. It covers general principles like accuracy, precision, sensitivity, and dynamic characteristics. Measurement systems have sensing elements, conditioning circuits, processing elements, and presentation outputs. Sensors convert non-electrical quantities into electrical signals based on physical principles like resistance, induction, thermoelectric effects, and more.