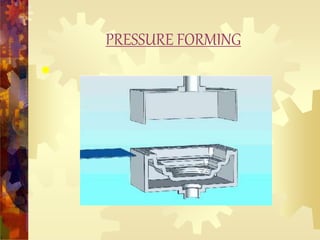

Thermoplastics are polymers that become moldable above a certain temperature and harden upon cooling. Injection molding is a common molding process where thermoplastic is heated, injected into a mold under high pressure, and solidifies. It is used for mass production of parts with complex shapes and high accuracy like toys, containers, and automobile parts. Blow molding uses air pressure to inflate hot plastic into a mold, while thermoforming shapes heated plastic sheets over molds using vacuum or pressure forming. Both processes are used to make packaging and large plastic items.