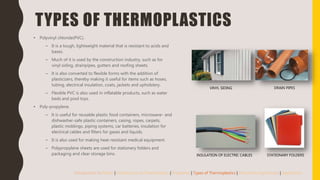

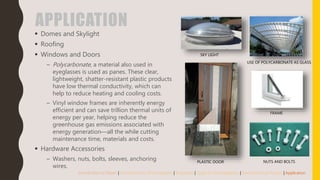

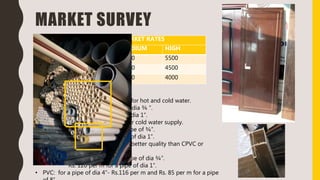

This document provides an overview of thermoplastics, including their properties, types, applications, and market rates. Thermoplastics are plastics that can be remolded and reused, as they soften when heated but do not undergo chemical changes. Common thermoplastics include polyvinyl chloride (PVC), polypropylene, polyethylene, and methacrylate. Thermoplastics have a variety of applications in construction, including use in roofing, windows, flooring, and temporary structures. The document concludes by listing market rates for thermoplastic pipes from different manufacturers.