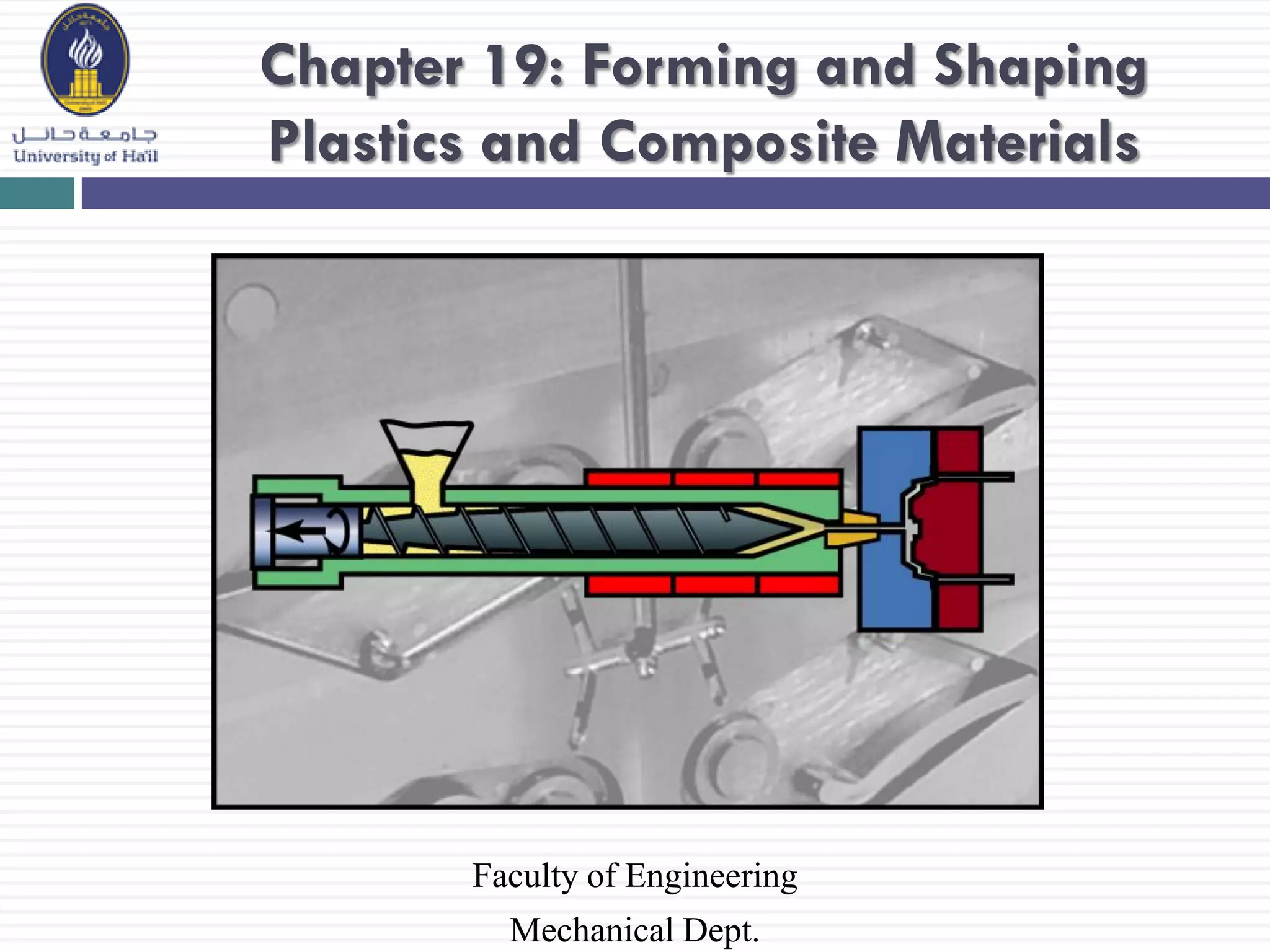

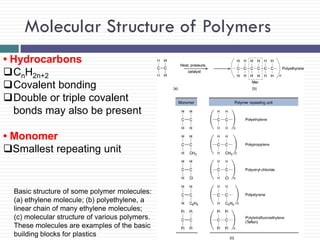

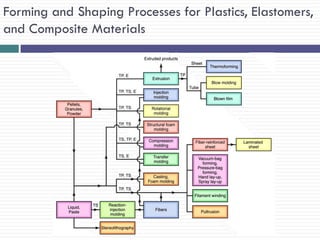

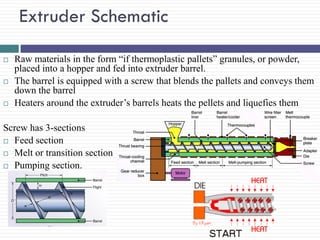

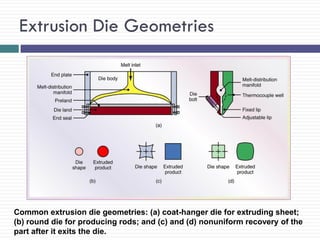

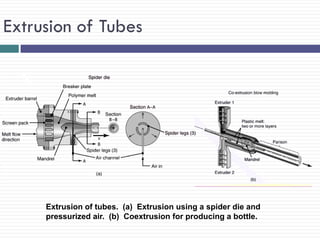

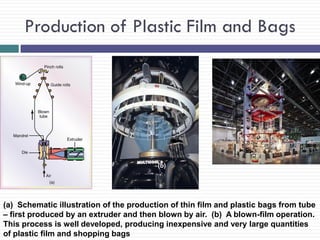

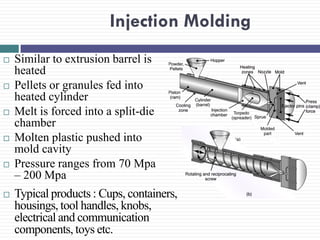

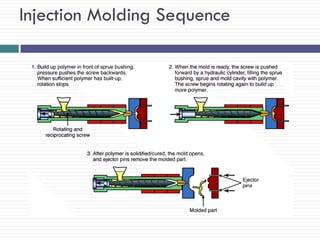

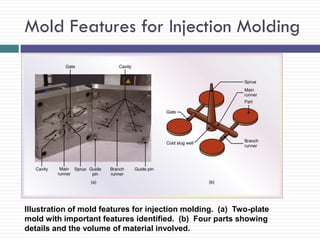

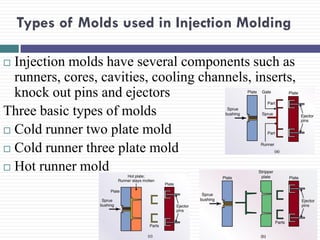

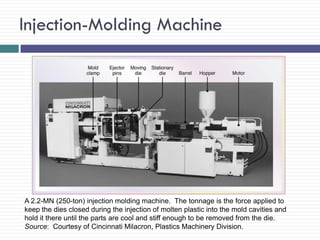

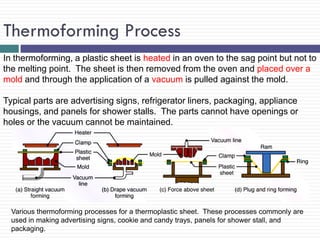

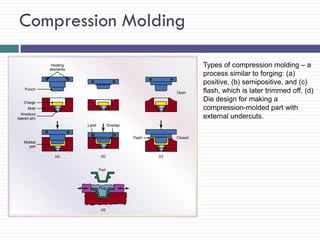

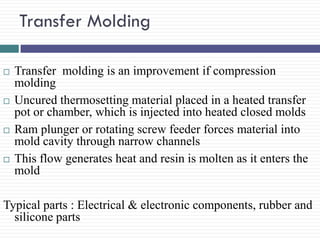

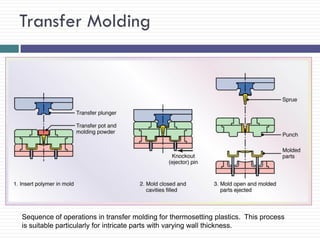

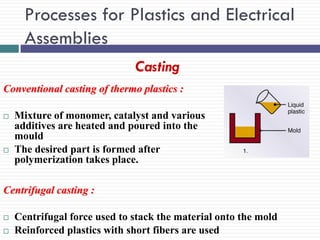

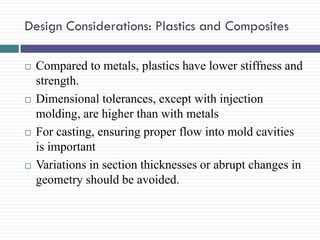

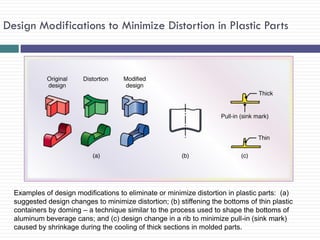

This document provides an overview of forming and shaping processes for plastics and composite materials. It begins with introductions to plastics and polymers, discussing their molecular structures and common types. Key plastic forming methods are then described in detail, including extrusion, injection molding, blow molding, rotational molding, thermoforming, compression molding, and transfer molding. Each method is defined, key process parameters are given, and examples of common applications are provided. The document serves as a comprehensive reference on the main industrial techniques for processing plastics into final products and parts.