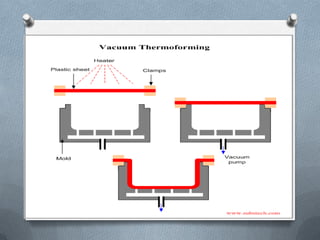

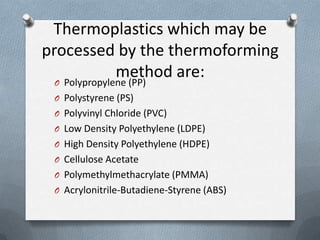

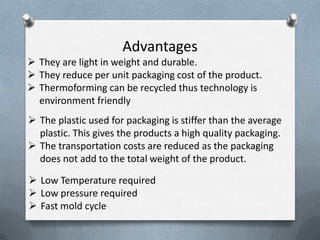

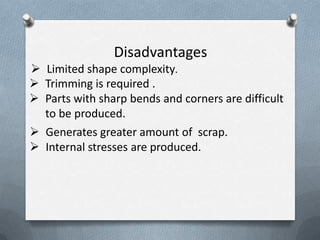

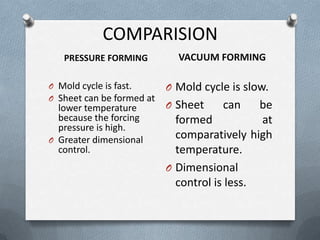

This document provides an overview of thermoforming and thermoplastics from the 1940s to today. It discusses how thermoforming was used for early applications like windshields and food packaging in the 1940s-1950s as production volumes increased. By the 1980s, thermoforming provided more flexibility in container sizes. Today, thermoforming is used not just for packaging but also for items like refrigerator liners, bath tubs, and automotive parts. The document also provides details on the different types of thermoforming like vacuum, pressure, and mechanical thermoforming as well as commonly thermoformed thermoplastics.