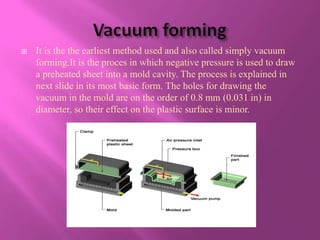

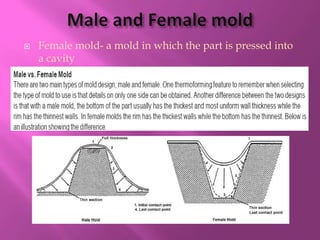

Thermoforming is a process where a heated plastic sheet is formed into a desired shape using pressure, vacuum, or mechanical methods. The key steps are heating the sheet, clamping it, and forming it using pressure or vacuum against a mold. Common applications include packaging, bathtubs, and large parts. Mass production uses thermoforming for thin packaging like blister packs while thicker sheets make larger parts like machine covers or boat hulls.