Plastics manufacturing processes

•

3 likes•5,422 views

The document summarizes the key steps in the plastic manufacturing process: 1. Acquiring raw materials like petrochemicals or plant-derived sources and synthesizing polymers through addition or condensation reactions. 2. Adding chemicals to achieve desired properties like color, strength or flexibility. 3. Shaping plastics through processes like extrusion, injection molding, or compression molding to form the final product.

Report

Share

Report

Share

Download to read offline

Recommended

Lecture: Polymer Processing

Lecture notes on Structure and Properties of Engineering Polymers

Course Objectives:

The main objective is to introduce polymers as an engineering material and emphasize the basic concepts of their nature, production and properties. Polymers are introduced at three levels; namely, the molecular level, the micro level, and macro-level. Through knowledge of all three levels, student can understand and predict the properties of various polymers and their performance in different products. The course also aims at introducing the students to the principles of polymer processing techniques and considerations of design using engineering polymers.

Processing and applications of polymers

this presentation is for polymer processing and their applications. it includes diffrent process through which we process polymers and make use of them in our daily life.

Fabrication of plastics

Fabrication of Plastics in polymer technology for B.Tech students in India specially for JNTU K,H&A in Andhra Pradesh Telangana and also for other Indian Universities.

By

Gurram.Achyuth Kumar

A

Plastics ( manufacture, types,application,examples)

all details about plastics including manufacture, synthesis, types, applications

Fibre Reinforced Plastic manufacturing methods

Composites manufacturing processes are complex, and involve combinations of the following physical processes:

1) Reinforcement Shaping

2) Resin Infusion

3) Composite Consolidation

Advantages and disadvantages of processing techniques

plastic composite manufacturing

Hand Lay-up

Spray up method

Filament winding

Match die molding

Pultrusion

Resin transfer molding

Reaction injection molding

Hand Lay-Up is well suited for low volume production of product.

This method can be used for both corrosion barrier and the structural portion

Fiber is chopped in a hand-held gun and fed into a spray of catalyzed resin directed at the mold. The deposited materials are left to cure under standard atmospheric conditions.

Recommended

Lecture: Polymer Processing

Lecture notes on Structure and Properties of Engineering Polymers

Course Objectives:

The main objective is to introduce polymers as an engineering material and emphasize the basic concepts of their nature, production and properties. Polymers are introduced at three levels; namely, the molecular level, the micro level, and macro-level. Through knowledge of all three levels, student can understand and predict the properties of various polymers and their performance in different products. The course also aims at introducing the students to the principles of polymer processing techniques and considerations of design using engineering polymers.

Processing and applications of polymers

this presentation is for polymer processing and their applications. it includes diffrent process through which we process polymers and make use of them in our daily life.

Fabrication of plastics

Fabrication of Plastics in polymer technology for B.Tech students in India specially for JNTU K,H&A in Andhra Pradesh Telangana and also for other Indian Universities.

By

Gurram.Achyuth Kumar

A

Plastics ( manufacture, types,application,examples)

all details about plastics including manufacture, synthesis, types, applications

Fibre Reinforced Plastic manufacturing methods

Composites manufacturing processes are complex, and involve combinations of the following physical processes:

1) Reinforcement Shaping

2) Resin Infusion

3) Composite Consolidation

Advantages and disadvantages of processing techniques

plastic composite manufacturing

Hand Lay-up

Spray up method

Filament winding

Match die molding

Pultrusion

Resin transfer molding

Reaction injection molding

Hand Lay-Up is well suited for low volume production of product.

This method can be used for both corrosion barrier and the structural portion

Fiber is chopped in a hand-held gun and fed into a spray of catalyzed resin directed at the mold. The deposited materials are left to cure under standard atmospheric conditions.

Thermoplastics : Introduction,classification,Processing & applications

Thermoplastics : Introduction,classification,Processing & applications

Plastic manufacturing "forming and shaping plastics"

how plastic products are manufactured?

what are the processes involved in manufacturing of these products?

what are the various machine tools used?

what are the various types of plastics and what is resin?

what are the diffrent steps in manufacturing?

Get all these answers in this presentation.

Glass Fiber Polymers

These are the composite materials made up of polymers with the addition of fibers

These are stronger and lighter in weight

Resin Transfer Molding

My presentation on resin transfer molding. Not much description included. For reference i would recommend

" Composite manufacturing by Sanjay Mazumdar".

Polymer Extrusion problems & Defects

This ppt uses pictures and causes to describe different polymer extrusion defects and how to avoid them.

It mainly focuses on polymers

Melamine Formaldehyde

Melamine resin or melamine formaldehyde is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. The presentation includes the preparation of MF, its properties and applications.

Structural foam molding 1

description of the process, advantages, disadvantages, applications by reshmi. r of anna university

Rubber

Rana zia ur rehman

Graduate Reseracher at KASIT (Korea Advanced of science & Technology)

My Email ID: ranazia517@gmail.com

More Related Content

What's hot

Thermoplastics : Introduction,classification,Processing & applications

Thermoplastics : Introduction,classification,Processing & applications

Plastic manufacturing "forming and shaping plastics"

how plastic products are manufactured?

what are the processes involved in manufacturing of these products?

what are the various machine tools used?

what are the various types of plastics and what is resin?

what are the diffrent steps in manufacturing?

Get all these answers in this presentation.

Glass Fiber Polymers

These are the composite materials made up of polymers with the addition of fibers

These are stronger and lighter in weight

Resin Transfer Molding

My presentation on resin transfer molding. Not much description included. For reference i would recommend

" Composite manufacturing by Sanjay Mazumdar".

Polymer Extrusion problems & Defects

This ppt uses pictures and causes to describe different polymer extrusion defects and how to avoid them.

It mainly focuses on polymers

Melamine Formaldehyde

Melamine resin or melamine formaldehyde is a hard, thermosetting plastic material made from melamine and formaldehyde by polymerization. The presentation includes the preparation of MF, its properties and applications.

Structural foam molding 1

description of the process, advantages, disadvantages, applications by reshmi. r of anna university

Rubber

Rana zia ur rehman

Graduate Reseracher at KASIT (Korea Advanced of science & Technology)

My Email ID: ranazia517@gmail.com

What's hot (20)

Thermoplastics : Introduction,classification,Processing & applications

Thermoplastics : Introduction,classification,Processing & applications

Plastic manufacturing "forming and shaping plastics"

Plastic manufacturing "forming and shaping plastics"

CHAPTER 6 Strength, creep and fracture of polymers.ppt

CHAPTER 6 Strength, creep and fracture of polymers.ppt

Similar to Plastics manufacturing processes

PLASTIC MOULDING and Methods involving in it

plastic moulding a topic with some less knowledges

but surely help out the masters as well as unger graduates in their assignments

no need to modify just go through it and take some innovative ideas and some will be making some more better ones

but for those who are in a hurry and want to minimise their time or wants to save their time its a copmlete package just go through it

Polymer industries

These synthetic materials have added new manufacturing methods and supplemented metals, wood and even ceramics in construction.

Chapter 3 part 4 - Polymer Matrix Composite shaping processes (2).pptx

Polymer Matrix Composite shaping processes

Spun Laid Process, Melt Blown Process, Differences between spun laid Process ...

Spun Laid Process, Melt Blown Process, Differences between spun laid Process ...MD. SAJJADUL KARIM BHUIYAN

Spun Laid Process, Melt Blown Process, Differences between spun laid Process and Melt Blown ProcessSimilar to Plastics manufacturing processes (20)

Chapter 3 part 4 - Polymer Matrix Composite shaping processes (2).pptx

Chapter 3 part 4 - Polymer Matrix Composite shaping processes (2).pptx

Spun Laid Process, Melt Blown Process, Differences between spun laid Process ...

Spun Laid Process, Melt Blown Process, Differences between spun laid Process ...

Recently uploaded

一比一原版(Glasgow毕业证书)格拉斯哥大学毕业证成绩单如何办理

原件一模一样【微信:6496090 】【(Glasgow毕业证书)格拉斯哥大学毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

一比一原版(毕业证)长崎大学毕业证成绩单如何办理

一模一样【q/微:1954292140】【(毕业证)长崎大学毕业证成绩单Offer】【q/微:1954292140】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

【业务选择办理准则】

一、工作未确定,回国需先给父母、亲戚朋友看下文凭的情况,办理一份就读学校的毕业证【q/微:1954292140】文凭即可

二、回国进私企、外企、自己做生意的情况,这些单位是不查询毕业证真伪的,而且国内没有渠道去查询国外文凭的真假,也不需要提供真实教育部认证。鉴于此,办理一份毕业证【q/微:1954292140】即可

三、进国企,银行,事业单位,考公务员等等,这些单位是必需要提供真实教育部认证的,办理教育部认证所需资料众多且烦琐,所有材料您都必须提供原件,我们凭借丰富的经验,快捷的绿色通道帮您快速整合材料,让您少走弯路。

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

一比一原版(Brunel毕业证书)布鲁内尔大学毕业证成绩单如何办理

原件一模一样【微信:6496090 】【(Brunel毕业证书)布鲁内尔大学毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

一比一原版(RHUL毕业证书)伦敦大学皇家霍洛威学院毕业证如何办理

学校原件一模一样【微信:6496090 】【(RHUL毕业证书)伦敦大学皇家霍洛威学院毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(RHUL毕业证书)伦敦大学皇家霍洛威学院毕业证【微信:6496090 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(RHUL毕业证书)伦敦大学皇家霍洛威学院毕业证【微信:6496090 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(RHUL毕业证书)伦敦大学皇家霍洛威学院毕业证【微信:6496090 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(RHUL毕业证书)伦敦大学皇家霍洛威学院毕业证【微信:6496090 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

一比一原版(MMU毕业证书)曼彻斯特城市大学毕业证成绩单如何办理

学校原件一模一样【微信:6496090 】【(MMU毕业证书)曼彻斯特城市大学毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(MMU毕业证书)曼彻斯特城市大学毕业证【微信:6496090 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(MMU毕业证书)曼彻斯特城市大学毕业证【微信:6496090 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(MMU毕业证书)曼彻斯特城市大学毕业证【微信:6496090 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(MMU毕业证书)曼彻斯特城市大学毕业证【微信:6496090 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

Design Thinking Design thinking Design thinking

browser_id=0805f5bf-ce9a-4428-95d6-d033e2e99357; country_code=HK; osano_consentmanager_uuid=e15f0d2d-abea-4bd1-8577-fd4496790f18; osano_consentmanager=jLf5tMmyGrJqqkCKKefFwIVpDtiqgmGXw27g5gYdfQpk4hOXYBfZCKCzPBWYdK8w1lcTqLap8QS67svOUbat03XkUWKpqKEsLCK3mjSUmA3OnMuRFuNcW9HVt3YeaJgOUXcJUn5WeIq8q9VtmrJKMuvXgOOyCNgJWMAZwoEMWDFkG3j7qcUcs1NPsqtUuw0j0wfj8i4zlaJfa3IvQPG_D4D260JFXkQhYznGXb5sE5mPs-APZIQtxPHmFwkJdDYoBoMM5i6BZTOE3CooiHLlsht3rOOPQg88XYMzui4zjk9McsqToNHwDRV6b9Kej7cm8wKYlnWd2VvhLptTLhhm5ZKtGgKGzvw1_typZRzwu9MKcBj0yTeYwGRJRAKuVn47zkhpHSgnz6D1l16vepyuyiQ8MPZIOh8c_uGbHMcyoaVTDaayQ8U8px9wRqFxUSyZEpQTa_fi5T-6Uz_R67Brn2PS-d4tvXLr66ldhAZ1Jf__4OIznZdrqvDR_Z2ebTeVTu5ATJ1DvLZ4i1BLFhcurWlu5l8T0-Jhw6DJ34hHUusbWzObZ3YFnj__0ei7tWJgFrkFO9CJagQ3viMmBxQ7AkTVJEHyjWU9; _fs_sample_user=false; _cookie_id=0a94bc58797e85f5de6c93345f64781e; __utma=186399478.1905777825.1717386827.1717386827.1717386827.1; __utmc=186399478; __utmz=186399478.1717386827.1.1.utmcsr=(direct)|utmccn=(direct)|utmcmd=(none); logged_in=MjUwNTA4MTg3--b7017508f246f17817fd3e608989a3ea5afca79b; _uv_id=30907880; __utmv=186399478.|1=member_type=FREE=1; __utmt=1; split=%7B%22connatix_player%22%3A%22control%22%7D; _li_dcdm_c=.slideshare.net; _lc2_fpi=064716c27ff8--01hze4afgcx42z2sfzncwg116f; _lc2_fpi_meta=%7B%22w%22%3A1717387476492%7D; cookie=579db3e3-4e1c-4ac9-a9db-002f2d678eef; cookie_cst=zix7LPQsHA%3D%3D; _lr_retry_request=true; _lr_env_src_ats=false; ccuid=70541430-c837-48de-9b38-b4f3df46fe15; ccsid=a9cca90f-eb12-4a61-b312-3155fe2cedc9; pbjs_fabrickId_cst=VyxHLMwsHQ%3D%3D; __qca=P0-718305261-1717387477147; _au_1d=AU1D-0100-001717387478-RZGCHPIP-HI28; cnx_userId=1a25f8b38d594f66bdfcd9b623574d7e; __gads=ID=b0c257cd8837a2d5:T=1717387477:RT=1717387477:S=ALNI_MZemOB79GYzmJy3MDitud8C8ts5nA; __gpi=UID=00000e3fd92e5908:T=1717387477:RT=1717387477:S=ALNI_MZR3uQlHjpZGt6pPAiR8bAmgQiNMw; __eoi=ID=120019e4653fcac0:T=1717387477:RT=1717387477:S=AA-Afja3ZyvegUx9PpJpyU3JRtKG; _ga=GA1.2.1905777825.1717386827; _gid=GA1.2.1124439812.1717387480; pbjs_fabrickId=%7B%22fabrickId%22%3A%22E1%3AZZkbPxuXzPC-yttqf7OyQwqyZ4d59gxkbK9Q9mAMU6KKtKk-zyILipMXIxtHYjde-k20DDHHi6M_4jJU4r9LAuwgRg_9_51CF7Sii2B_ST0%22%7D; flash=BAh7DEkiDHN1Y2Nlc3MGOgZFRjBJIgtub3RpY2UGOwBGMEkiDHdhcm5pbmcGOwBGMEkiDG1lc3NhZ2UGOwBGMEkiCmVycm9yBjsARjBJIg5wZXJtYW5lbnQGOwBGMEkiEW1vZGFsX25vdGljZQY7AEYw--f6b5339a8f734d46392574bf61fd69c472ec51d6; __utmb=186399478.31.7.1717387752666; _dd_s=rum=0&expire=1717388665794

PORTFOLIO FABIANA VILLANI ARCHITECTURE.pdf

Hello everyone! I am thrilled to present my latest portfolio on LinkedIn, marking the culmination of my architectural journey thus far. Over the span of five years, I've been fortunate to acquire a wealth of knowledge under the guidance of esteemed professors and industry mentors. From rigorous academic pursuits to practical engagements, each experience has contributed to my growth and refinement as an architecture student. This portfolio not only showcases my projects but also underscores my attention to detail and to innovative architecture as a profession.

Design Thinking Design thinking Design thinking

https://www.google.com/maps/d/view?mid=1deXTRaa0CGg1QvFHlnVvmlnp4FPtZ10&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/view?mid=1BHv3gx5ZJJH3inU343hkNLpPQCv6KPo&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/view?mid=1AfH4_M3zoT6_s93ASy0CeE8jovcHgik&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/view?mid=19QktXHVSUwDqMFK3CcLocgXQ6bPz5b8&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/view?mid=1w11lKJgVGX6rOP4J7J1PCJie86IWQVM&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/view?mid=1kVcrH9p-f2MJdJ6voQGvC1P35jx-QZ8&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/view?mid=149RlyyVXCaY65ql-dLC2eZ1fsP01JN8&vomp=1&cid=mp&cv=RgEAcd5aUzg.en.

https://www.google.com/maps/d/view?mid=1jtRQWjvBCrEFjsvsEIDLcLy-VAyeVHY&vomp=1&cid=mp&cv=RgEAcd5aUzg.en.

https://www.google.com/maps/d/view?mid=1L5nx5uSpbzk3VDdxpuIX8TzOM2ZUA4E&vomp=1&cid=mp&cv=RgEAcd5aUzg.en.

https://www.google.com/maps/d/view?mid=1L5nx5uSpbzk3VDdxpuIX8TzOM2ZUA4E&vomp=1&cid=mp&cv=RgEAcd5aUzg.en.

https://www.google.com/maps/d/view?mid=1SudZO_xD1NsTUsnvMCZtPgAHMpZCIaI&ll=22.39653737546966%2C114.10949749999997&z=12

https://www.google.com/maps/d/view?mid=1xl8SHD1eLjf4PbIhmeodTYJF4dPX4oo&ll=22.39653737546966%2C114.10949749999997&z=12

https://www.google.com/maps/d/view?mid=1LikThZPD8S6wG37Lnt1VWYWjBZ4IL_0&ll=22.39653737546966%2C114.10949749999997&z=12

https://www.google.com/maps/d/view?mid=1xl8SHD1eLjf4PbIhmeodTYJF4dPX4oo&ll=22.39653737546966%2C114.10949749999997&z=12

https://www.google.com/maps/d/view?mid=149RlyyVXCaY65ql-dLC2eZ1fsP01JN8&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1m72ggtGeWoLJnHpU_3f7LZ-HUQv2Mzk&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1F2NYKICN0Wb27ewNUsrV2BB18wvP7GQ&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1eKeVRSRhyfqRrG0F9kQiD5yp0cGt4WQ&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1g6bB3w3qRleJoX2Psz1zPggAUxwnCdU&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1sGPo5jqk_loy-a1es93BLxTKvRXmxt4&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1vaAt-Vy9I85rMukOc65MQmt3SoNBpNQ&ll=22.396537375469673%2C114.10949749999997&z=11

https://www.google.com/maps/d/viewer?mid=1r62eAttQMFxuaZeIVC_YF_aqPADXnf8&ll=22.396537375469673%2C114.10949749999997&z=11

Common Designing Mistakes and How to avoid them

You could be a professional graphic designer and still make mistakes. There is always the possibility of human error. On the other hand if you’re not a designer, the chances of making some common graphic design mistakes are even higher. Because you don’t know what you don’t know. That’s where this blog comes in. To make your job easier and help you create better designs, we have put together a list of common graphic design mistakes that you need to avoid.

一比一原版(CITY毕业证书)谢菲尔德哈勒姆大学毕业证如何办理

学校原件一模一样【微信:6496090 】【(CITY毕业证书)谢菲尔德哈勒姆大学毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(CITY毕业证书)谢菲尔德哈勒姆大学毕业证【微信:6496090 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(CITY毕业证书)谢菲尔德哈勒姆大学毕业证【微信:6496090 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(CITY毕业证书)谢菲尔德哈勒姆大学毕业证【微信:6496090 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(CITY毕业证书)谢菲尔德哈勒姆大学毕业证【微信:6496090 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

Can AI do good? at 'offtheCanvas' India HCI prelude

Invited talk at 'offtheCanvas' IndiaHCI prelude, 29th June 2024.

https://www.alandix.com/academic/talks/offtheCanvas-IndiaHCI2024/

The world is being changed fundamentally by AI and we are constantly faced with newspaper headlines about its harmful effects. However, there is also the potential to both ameliorate theses harms and use the new abilities of AI to transform society for the good. Can you make the difference?

一比一原版(Bristol毕业证书)布里斯托大学毕业证成绩单如何办理

原件一模一样【微信:6496090 】【(Bristol毕业证书)布里斯托大学毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

Exploring the Future of Smart Garages.pdf

Dive into the innovative world of smart garages with our insightful presentation, "Exploring the Future of Smart Garages." This comprehensive guide covers the latest advancements in garage technology, including automated systems, smart security features, energy efficiency solutions, and seamless integration with smart home ecosystems. Learn how these technologies are transforming traditional garages into high-tech, efficient spaces that enhance convenience, safety, and sustainability.

Ideal for homeowners, tech enthusiasts, and industry professionals, this presentation provides valuable insights into the trends, benefits, and future developments in smart garage technology. Stay ahead of the curve with our expert analysis and practical tips on implementing smart garage solutions.

一比一原版(LSE毕业证书)伦敦政治经济学院毕业证成绩单如何办理

原件一模一样【微信:6496090 】【(LSE毕业证书)伦敦政治经济学院毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

Book Formatting: Quality Control Checks for Designers

This presentation was made to help designers who work in publishing houses or format books for printing ensure quality.

Quality control is vital to every industry. This is why every department in a company need create a method they use in ensuring quality. This, perhaps, will not only improve the quality of products and bring errors to the barest minimum, but take it to a near perfect finish.

It is beyond a moot point that a good book will somewhat be judged by its cover, but the content of the book remains king. No matter how beautiful the cover, if the quality of writing or presentation is off, that will be a reason for readers not to come back to the book or recommend it.

So, this presentation points designers to some important things that may be missed by an editor that they could eventually discover and call the attention of the editor.

一比一原版(UCB毕业证书)伯明翰大学学院毕业证成绩单如何办理

原件一模一样【微信:6496090 】【(UCB毕业证书)伯明翰大学学院毕业证成绩单】【微信:6496090 】学位证,留信认证(真实可查,永久存档)offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微6496090

【主营项目】

一.毕业证【q微6496090】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微6496090】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

Expert Accessory Dwelling Unit (ADU) Drafting Services

Whether you’re looking to create a guest house, a rental unit, or a private retreat, our experienced team will design a space that complements your existing home and maximizes your investment. We provide personalized, comprehensive expert accessory dwelling unit (ADU)drafting solutions tailored to your needs, ensuring a seamless process from concept to completion.

Top 5 Indian Style Modular Kitchen Designs

Get the perfect modular kitchen in Gurgaon at Finzo! We offer high-quality, custom-designed kitchens at the best prices. Wardrobes and home & office furniture are also available. Free consultation! Best Quality Luxury Modular kitchen in Gurgaon available at best price. All types of Modular Kitchens are available U Shaped Modular kitchens, L Shaped Modular Kitchen, G Shaped Modular Kitchens, Inline Modular Kitchens and Italian Modular Kitchen.

Recently uploaded (20)

Коричневый и Кремовый Деликатный Органический Копирайтер Фрилансер Марке...

Коричневый и Кремовый Деликатный Органический Копирайтер Фрилансер Марке...

Can AI do good? at 'offtheCanvas' India HCI prelude

Can AI do good? at 'offtheCanvas' India HCI prelude

Book Formatting: Quality Control Checks for Designers

Book Formatting: Quality Control Checks for Designers

Expert Accessory Dwelling Unit (ADU) Drafting Services

Expert Accessory Dwelling Unit (ADU) Drafting Services

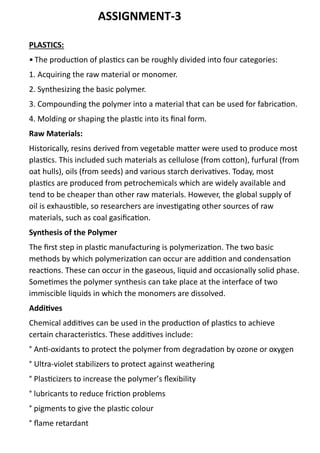

Plastics manufacturing processes

- 1. ASSIGNMENT-3 PLASTICS: •The production of plastics can be roughly divided into four categories: 1. Acquiring the raw material or monomer. 2. Synthesizing the basic polymer. 3. Compounding the polymer into a material that can be used for fabrication. 4. Molding or shaping the plastic into its final form. Raw Materials: Historically, resins derived from vegetable matter were used to produce most plastics. This included such materials as cellulose (from cotton), furfural (from oat hulls), oils (from seeds) and various starch derivatives. Today, most plastics are produced from petrochemicals which are widely available and tend to be cheaper than other raw materials. However, the global supply of oil is exhaustible, so researchers are investigating other sources of raw materials, such as coal gasification. Synthesis of the Polymer The first step in plastic manufacturing is polymerization. The two basic methods by which polymerization can occur are addition and condensation reactions. These can occur in the gaseous, liquid and occasionally solid phase. Sometimes the polymer synthesis can take place at the interface of two immiscible liquids in which the monomers are dissolved. Additives Chemical additives can be used in the production of plastics to achieve certain characteristics. These additives include: ° Anti-oxidants to protect the polymer from degradation by ozone or oxygen ° Ultra-violet stabilizers to protect against weathering ° Plasticizers to increase the polymer’s flexibility ° lubricants to reduce friction problems ° pigments to give the plastic colour ° flame retardant

- 2. ASSIGNMENT-3 Plastics are often manufactured as composites. This is achieved by adding reinforcements such as glass or carbon fibers to the plastics, increasing their strength and stability. Plastic foam is a different type of composite which combines plastic and gas. An example of this can be seen in styro foam cups which are made of foamed polystyrene. Shaping and Finishing Compression molding is one of the oldest methods used for converting polymers into useful materials. It uses pressure to force the plastic into a certain shape. One half of a two-piece mold is filled with plastic and then the two halves of the mold are brought together and the plastic is melted under high pressure Methods used for shaping plastics are *EXTRUSION Plastics: Any, especially high density polythene; polystyrene and polyvinyl chloride; all synthetic fibres Tooling cost: Moderate Production volume: High but restricted to minimum order lengths Uses : Anything with a constant cross section: fibres; tubing; pipes; sheets; films; cable sheathing; profiles e.g. curtain rails or window frames

- 3. ASSIGNMENT-3 Tolerances: Standard industry tolerances usually provide adequate precision for most applications •Angular tolerances will be ± 1 to 2 degrees •Flatness tolerance across a profile is ± .004 per inch of width •Extrusions will be straight within 0.0125 inch per foot of length •The approximate twist tolerance will be .5 degrees per foot *INJECTION MOLDING Material is introduced into the injection moulding machine via a Hopper. Theinjection moulding machine consists of aheated barrel equipped with a reciprocatingscrew (driven by a hydraulic or electric motor), which feeds the molten polymer into a temperature controlled split mould via a channel system of gates and runners. • The screw melts (plasticizes) (plasticizes) the polymer, polymer,and also acts as a ram during the injection phase. The screw action also provides additional heating by virtue of the shearing action on the polymer. • The polymer is injected into a mould tool that defines the shape of the molded part

- 4. ASSIGNMENT-3 Plastics: Commonly all thermoplastics Marks: The plastic enters the mould through what is known as a gate which leaves a 'sprue' which is then broken off but leaves a slightly rough, often circular area; there are sometimes also smooth circular marks left by the ejector pins used to help release the warm moulding from the mould; mould lines are sometimes also visible. Tooling cost: High Production volume: High Uses : Precision technique capable of complicated shapes: e.g. medical components; cheap products produced in very large numbers: Lego; plastic cutlery; machine housings; washing-up bowl

- 5. ASSIGNMENT-3 Process comparison: * Typical values shown first (Feasible values in parentheses)