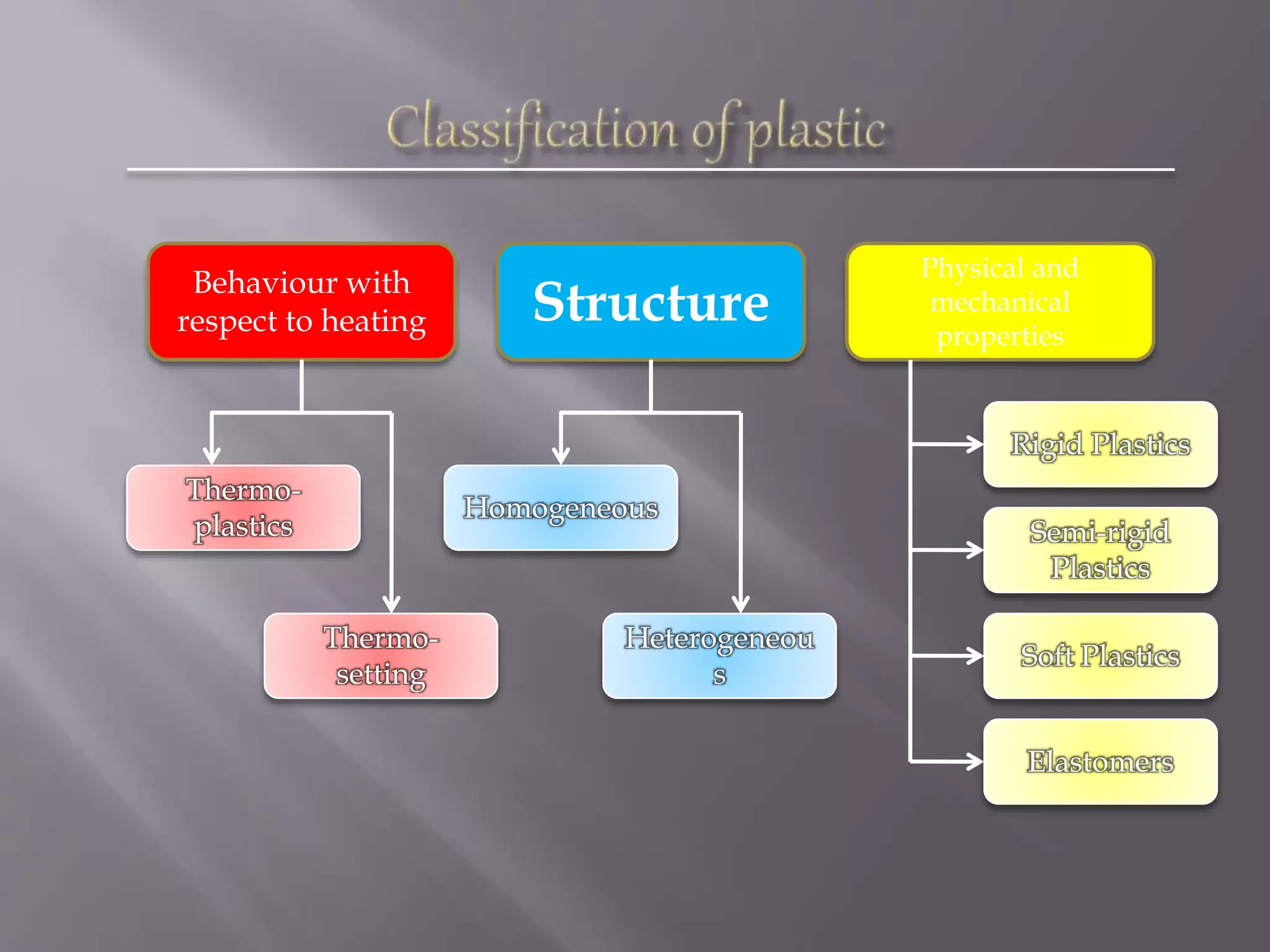

Plastic is a synthetic material made from organic polymers that can be molded into various shapes. There are two main types of plastics: thermoplastics and thermoset plastics. Thermoplastics soften when heated and harden when cooled, allowing them to be remolded and recycled. Thermoset plastics harden permanently once molded. Plastics have a variety of applications due to their properties like corrosion resistance, low cost, and ability to be molded into complex shapes. However, they also have weaknesses like low strength and sensitivity to heat and chemicals.