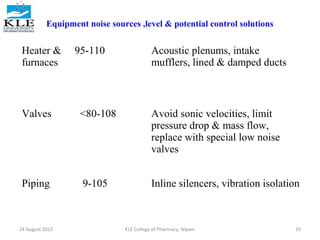

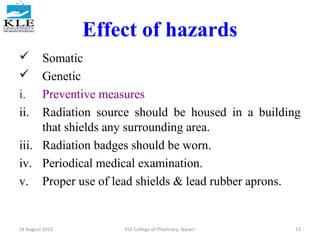

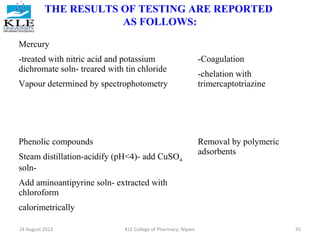

This document discusses various industrial hazards and safety measures. It begins with an introduction to industrial hazards and defines them. It then covers different types of hazards like heat and cold, noise, radiation, fire and explosions, chemicals, biological agents, mechanical and electrical hazards. For each type of hazard, the document discusses potential health effects and recommendations to prevent or minimize risks. It also addresses related topics like industrial effluent testing and treatment, classification of safety signs, and case studies of industrial accidents.