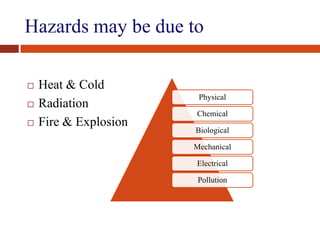

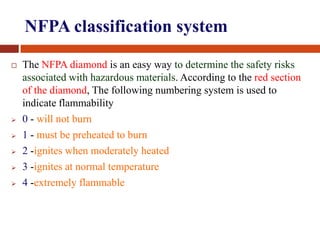

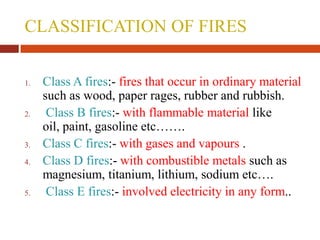

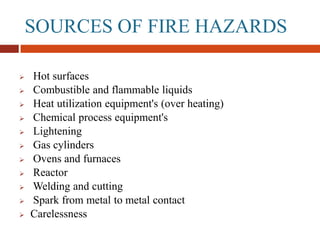

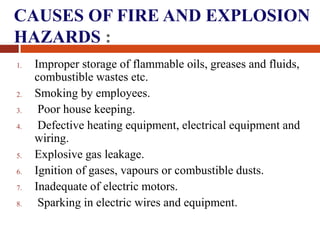

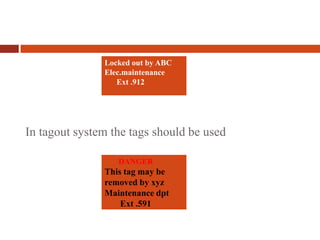

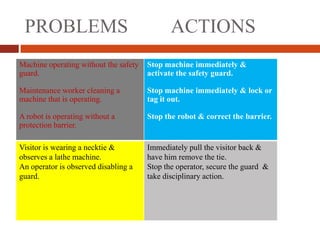

Industrial hazards can occur due to fires, mechanical issues, and electrical problems. Fires can be caused by improper storage of flammable materials, smoking, or defective equipment. Mechanical injuries happen through contact with machines and can be prevented using guards and lockout/tagout systems. Electrical shocks arise from improper wiring, insulation failures, or working on live circuits. Safety measures involve disconnecting power, inspecting equipment, using protective gear, and only allowing trained personnel to perform work.