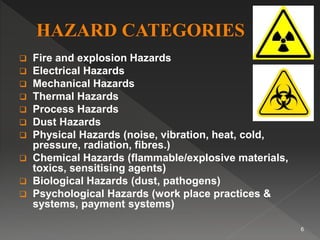

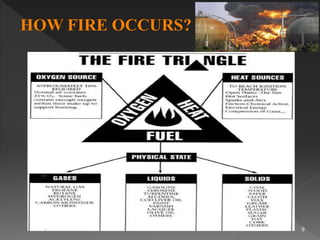

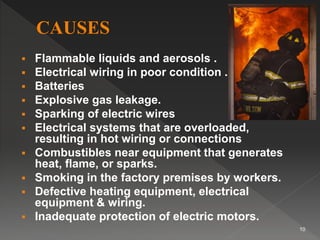

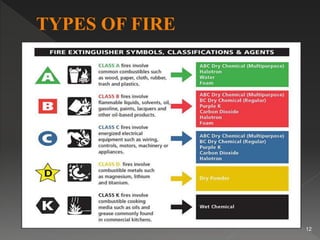

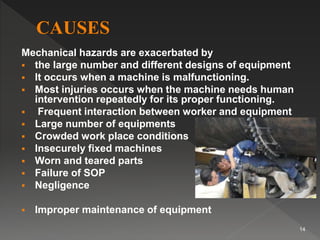

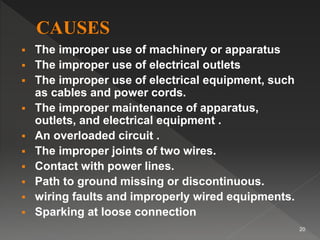

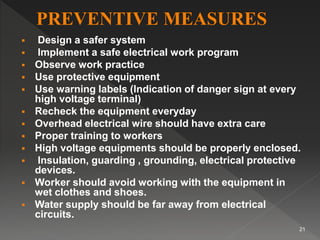

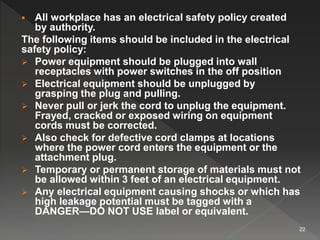

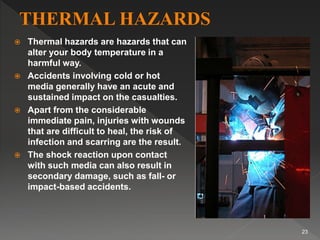

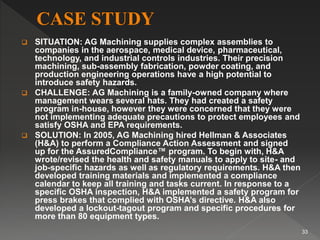

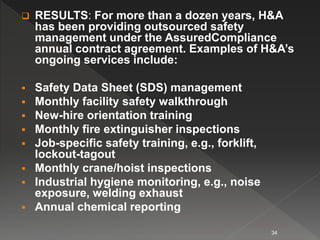

This document discusses various industrial hazards found in pharmaceutical manufacturing processes. It covers fire and explosion hazards, mechanical hazards, electrical hazards, thermal hazards, and process hazards. For each hazard type, the document discusses potential causes and recommended preventive measures. It provides an example case study of a manufacturing company that hired a consultant to improve its safety compliance after recognizing gaps in its in-house safety program. The document emphasizes the importance of identifying hazards, implementing engineering and administrative controls, and training workers to reduce risks in industrial processes.