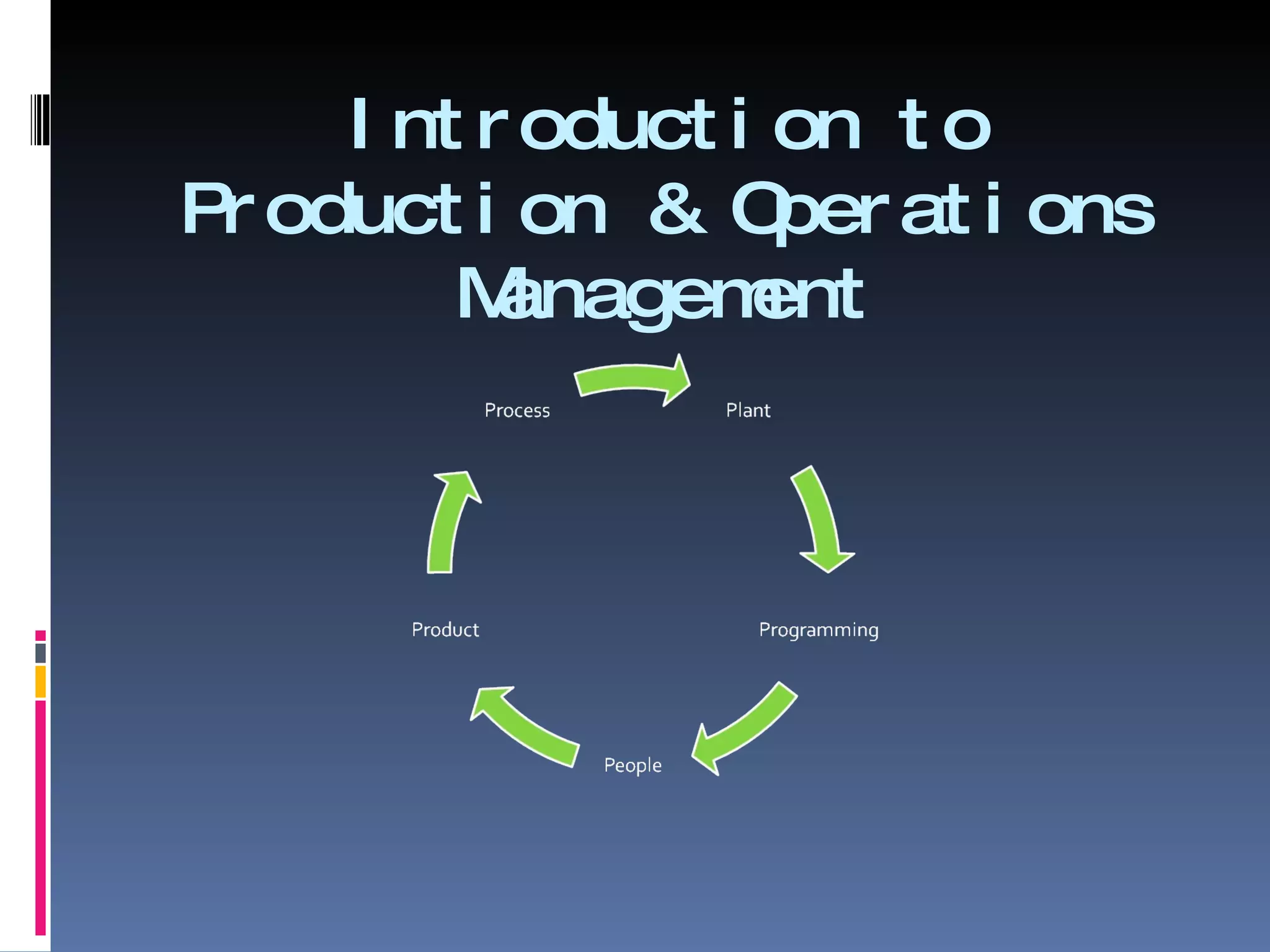

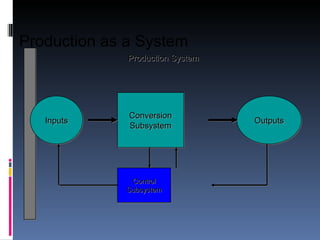

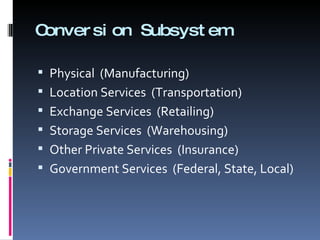

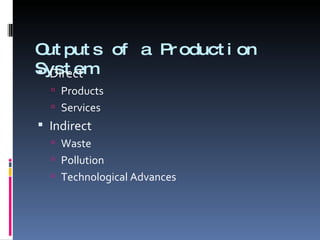

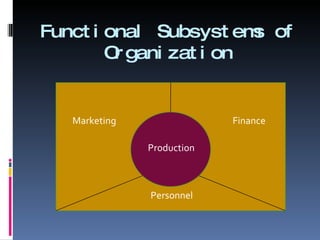

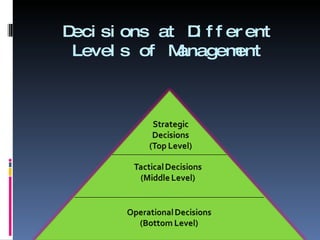

This document provides an introduction to production and operations management. It discusses how POM involves managing an organization's production system to take inputs and convert them into outputs. Today, POM is affected by factors like global competition and advances in technology. POM can be studied as a production system, an organizational function, and through decision making. As a system, production has inputs, conversion processes, and outputs. As a function, the operations department is critical to a company's success. Decision making in POM includes strategic, operating, and control decisions made at different management levels.